Additive manufacturing enables the creation of complex resin components with high precision and minimal material waste, outperforming conventional casting in design flexibility and customization. Unlike casting, which often requires molds and longer production cycles, additive techniques allow rapid prototyping and on-demand manufacturing directly from digital models. This efficiency reduces costs and lead times, making additive manufacturing an ideal choice for intricate and low-volume resin parts.

Table of Comparison

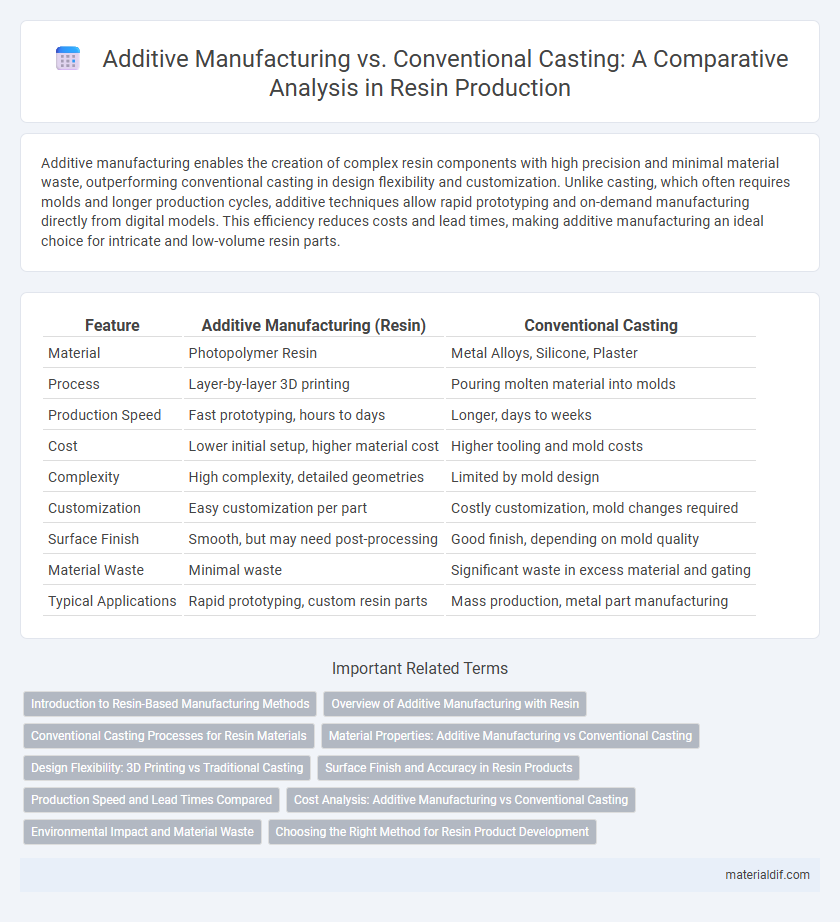

| Feature | Additive Manufacturing (Resin) | Conventional Casting |

|---|---|---|

| Material | Photopolymer Resin | Metal Alloys, Silicone, Plaster |

| Process | Layer-by-layer 3D printing | Pouring molten material into molds |

| Production Speed | Fast prototyping, hours to days | Longer, days to weeks |

| Cost | Lower initial setup, higher material cost | Higher tooling and mold costs |

| Complexity | High complexity, detailed geometries | Limited by mold design |

| Customization | Easy customization per part | Costly customization, mold changes required |

| Surface Finish | Smooth, but may need post-processing | Good finish, depending on mold quality |

| Material Waste | Minimal waste | Significant waste in excess material and gating |

| Typical Applications | Rapid prototyping, custom resin parts | Mass production, metal part manufacturing |

Introduction to Resin-Based Manufacturing Methods

Resin-based manufacturing methods, including additive manufacturing and conventional casting, utilize polymer resins to create detailed and complex parts with high precision. Additive manufacturing builds objects layer by layer using photopolymerization or extrusion of resin, enabling rapid prototyping and customization with minimal waste. Conventional casting involves pouring liquid resin into molds, making it suitable for bulk production of consistent parts but often requiring longer curing times and less geometric complexity.

Overview of Additive Manufacturing with Resin

Additive manufacturing with resin utilizes photopolymerization techniques such as stereolithography (SLA) and digital light processing (DLP) to create highly detailed and precise components layer by layer from liquid resin. This process offers enhanced design flexibility, reduced material waste, and faster prototyping compared to conventional casting, which relies on molds and often involves longer lead times and limited geometric complexity. Resin-based additive manufacturing enables rapid production of complex shapes with fine surface finishes, ideal for applications in dental, jewelry, and aerospace industries.

Conventional Casting Processes for Resin Materials

Conventional casting processes for resin materials involve pouring liquid resin into molds where it hardens through chemical or thermal curing, enabling detailed and smooth surface finishes suitable for functional prototypes and low-volume production. These methods, such as investment casting and compression molding, provide consistent mechanical properties and are cost-effective for repeated parts with complex geometries. Compared to additive manufacturing, conventional casting offers superior scalability and better material homogeneity, making it ideal for applications requiring high strength and durability in resin-based components.

Material Properties: Additive Manufacturing vs Conventional Casting

Additive manufacturing of resin materials enables precise control over microstructural properties, resulting in improved mechanical strength and reduced porosity compared to conventional casting. Resin components produced through additive processes exhibit superior customization in density and thermal resistance, enhancing performance in specialized applications. Conventional casting typically involves greater material waste and less uniformity, which can lead to inconsistencies in resin durability and surface finish.

Design Flexibility: 3D Printing vs Traditional Casting

Additive manufacturing using resin enables unprecedented design flexibility by allowing complex geometries and intricate details that are difficult or impossible to achieve with conventional casting methods. Unlike traditional casting, which relies on molds and is limited by their design constraints, 3D printing builds objects layer by layer, facilitating rapid prototyping and customization. This precise control over shape and structure accelerates product development and reduces material waste in resin-based additive manufacturing.

Surface Finish and Accuracy in Resin Products

Additive manufacturing with resin enables highly detailed surface finishes and impressive dimensional accuracy due to layer-by-layer precision and advanced stereolithography techniques. Conventional casting often results in rougher surfaces requiring post-processing to meet smoothness standards, and its accuracy is limited by mold quality and material shrinkage. Resin-based additive methods outperform casting by delivering intricate geometries and consistent tolerances essential for prototype and end-use components.

Production Speed and Lead Times Compared

Additive manufacturing with resin significantly reduces production speed and lead times by enabling rapid prototyping and on-demand fabrication without the need for molds, unlike conventional casting that involves lengthy mold creation and cooling phases. Resin-based 3D printing technologies such as SLA or DLP produce complex geometries directly from digital files, accelerating iteration cycles within hours rather than days or weeks. Conventional casting remains slower due to multiple preparatory steps, including pattern making and finishing, which prolong total production timelines.

Cost Analysis: Additive Manufacturing vs Conventional Casting

Additive manufacturing with resin typically incurs higher upfront costs due to expensive printers and materials but reduces waste and tooling expenses, offering cost efficiency for low-volume or custom parts. Conventional casting has lower initial equipment costs and benefits from economies of scale, making it more cost-effective for large production runs despite longer lead times and higher labor costs. Overall, additive manufacturing minimizes material waste and setup time, while conventional casting remains advantageous for mass production due to its lower per-unit cost.

Environmental Impact and Material Waste

Additive manufacturing using resin significantly reduces material waste compared to conventional casting by precisely depositing layers only where needed, minimizing excess resin usage. Conventional casting processes often generate substantial waste due to mold creation, excess runoff, and trimming of hardened resin parts. Environmentally, additive manufacturing lowers energy consumption and decreases emissions by eliminating the need for intensive mold production and reducing the volume of discarded resin materials.

Choosing the Right Method for Resin Product Development

Choosing the right method for resin product development depends on factors like design complexity, production volume, and cost-efficiency. Additive manufacturing excels in creating intricate geometries and rapid prototyping with minimal material waste, making it ideal for low-volume, customized resin parts. Conventional casting offers high durability and surface finish for large-scale production runs but requires longer setup times and higher initial costs.

Additive manufacturing vs Conventional casting Infographic

materialdif.com

materialdif.com