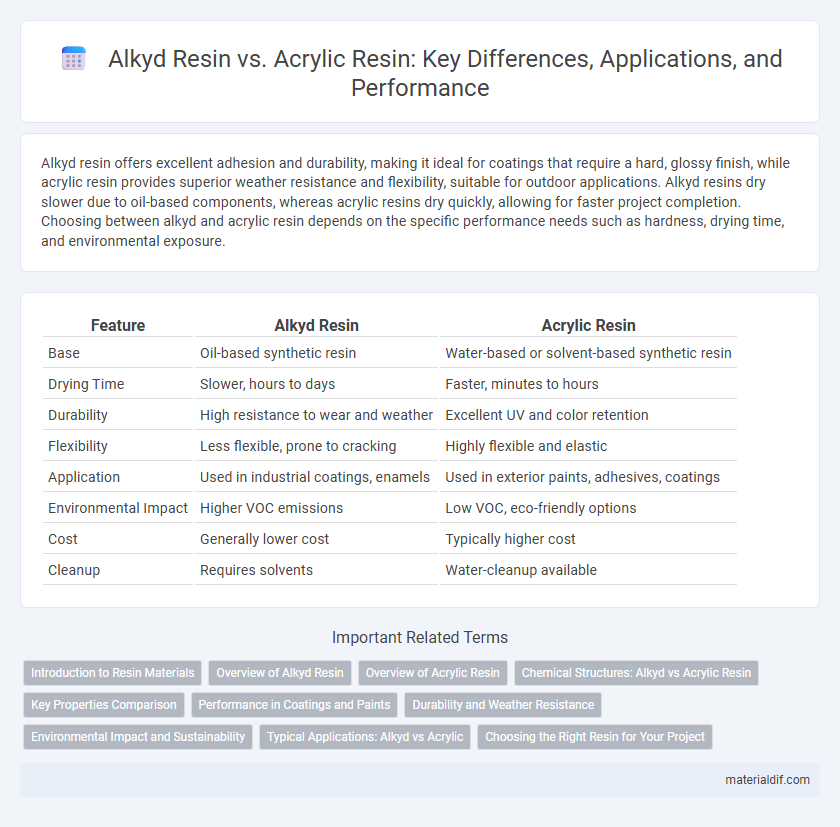

Alkyd resin offers excellent adhesion and durability, making it ideal for coatings that require a hard, glossy finish, while acrylic resin provides superior weather resistance and flexibility, suitable for outdoor applications. Alkyd resins dry slower due to oil-based components, whereas acrylic resins dry quickly, allowing for faster project completion. Choosing between alkyd and acrylic resin depends on the specific performance needs such as hardness, drying time, and environmental exposure.

Table of Comparison

| Feature | Alkyd Resin | Acrylic Resin |

|---|---|---|

| Base | Oil-based synthetic resin | Water-based or solvent-based synthetic resin |

| Drying Time | Slower, hours to days | Faster, minutes to hours |

| Durability | High resistance to wear and weather | Excellent UV and color retention |

| Flexibility | Less flexible, prone to cracking | Highly flexible and elastic |

| Application | Used in industrial coatings, enamels | Used in exterior paints, adhesives, coatings |

| Environmental Impact | Higher VOC emissions | Low VOC, eco-friendly options |

| Cost | Generally lower cost | Typically higher cost |

| Cleanup | Requires solvents | Water-cleanup available |

Introduction to Resin Materials

Alkyd resin is a polyester-based material commonly used in coatings and paints due to its excellent adhesion, flexibility, and durability. Acrylic resin, a thermoplastic polymer made from acrylic acid or methacrylic acid derivatives, offers superior weather resistance, color retention, and fast drying properties. Both resin types serve critical roles in industrial and decorative applications, with alkyd resin favored for traditional oil-based paints and acrylic resin preferred for water-based, high-performance coatings.

Overview of Alkyd Resin

Alkyd resin is a polyester-based polymer synthesized by the reaction of polyols, polyacids, and fatty acids or oils, commonly used in coatings, varnishes, and paints due to its excellent adhesion and flexibility. It offers superior chemical resistance and durability compared to other resins, with a drying time that varies depending on the oil length used in its formulation. Alkyd resins are valued in industrial and decorative applications for their cost-effectiveness and ability to provide a glossy and protective finish on various surfaces.

Overview of Acrylic Resin

Acrylic resin is a polymer primarily derived from acrylic acid or methacrylic acid, known for its excellent clarity, UV resistance, and weather durability. It offers superior fast-drying properties and flexibility compared to alkyd resin, making it ideal for coatings exposed to harsh outdoor environments. Acrylic resin's resistance to yellowing and cracking enhances the longevity of paints, adhesives, and sealants.

Chemical Structures: Alkyd vs Acrylic Resin

Alkyd resins are polyester-based compounds typically synthesized from polyols, dibasic acids, and fatty acids or oils, featuring ester linkages that contribute to their flexibility and durability. Acrylic resins are composed of polymerized acrylic acid or methacrylic acid derivatives, characterized by carbon-carbon backbone chains with pendant ester groups providing high clarity and UV resistance. The ester functionality in alkyd resins is part of the backbone, whereas in acrylic resins it is present in side chains, leading to distinct physical and chemical properties affecting performance in coatings and adhesives.

Key Properties Comparison

Alkyd resin features excellent adhesion, flexibility, and durability, making it ideal for coatings exposed to outdoor weather and mechanical stress, while acrylic resin offers superior UV resistance, color retention, and faster drying times suited for decorative and protective applications. Alkyd resins generally have higher solvent content and slower curing processes compared to the low-VOC, water-based, and environmentally friendly nature of acrylic resins. The choice between alkyd and acrylic resin depends on application requirements such as exposure conditions, drying time, and environmental regulations.

Performance in Coatings and Paints

Alkyd resin offers superior adhesion, flexibility, and durability in coatings, making it ideal for exterior applications exposed to harsh weather. Acrylic resin excels in color retention, UV resistance, and quick drying times, enhancing performance in decorative and automotive paints. Both resins provide strong film formation, but acrylic resins outperform alkyds in resistance to yellowing and chalking, ensuring longer-lasting finishes.

Durability and Weather Resistance

Alkyd resin offers strong adhesion and flexibility, making it highly durable in various applications, but it tends to yellow and degrade over prolonged UV exposure. Acrylic resin provides superior weather resistance and maintains color stability under harsh sunlight, ensuring long-lasting performance without cracking or fading. For outdoor durability, acrylic resin is generally preferred due to its excellent resistance to moisture, UV radiation, and temperature fluctuations.

Environmental Impact and Sustainability

Alkyd resin, derived from plant oils, offers partial biodegradability but releases higher VOCs (volatile organic compounds) during curing, contributing to air pollution. Acrylic resin, synthesized from petrochemicals, has a lower VOC emission and longer durability, reducing frequent repainting and waste generation. Sustainability efforts focus on bio-based acrylics and reformulated alkyds to minimize environmental impact while maintaining performance standards.

Typical Applications: Alkyd vs Acrylic

Alkyd resins are predominantly used in decorative and protective coatings for metal and wood surfaces, offering excellent durability and adhesion in architectural paints and industrial finishes. Acrylic resins excel in applications requiring superior weather resistance, color retention, and flexibility, making them ideal for automotive coatings, adhesives, and high-performance coatings in exterior environments. Both resin types serve distinct markets based on specific performance criteria, with alkyds favored for cost-effective interior and exterior paints and acrylics chosen for advanced coating technologies.

Choosing the Right Resin for Your Project

Alkyd resin offers excellent adhesion, flexibility, and durability, making it ideal for outdoor applications and metal coatings where corrosion resistance and weatherproofing are crucial. Acrylic resin provides superior UV resistance, color retention, and faster drying times, favored in art projects, indoor coatings, and environments requiring vibrant, long-lasting finishes. Selecting the right resin depends on factors such as exposure conditions, desired finish, drying time, and substrate compatibility to ensure optimal performance and longevity.

Alkyd Resin vs Acrylic Resin Infographic

materialdif.com

materialdif.com