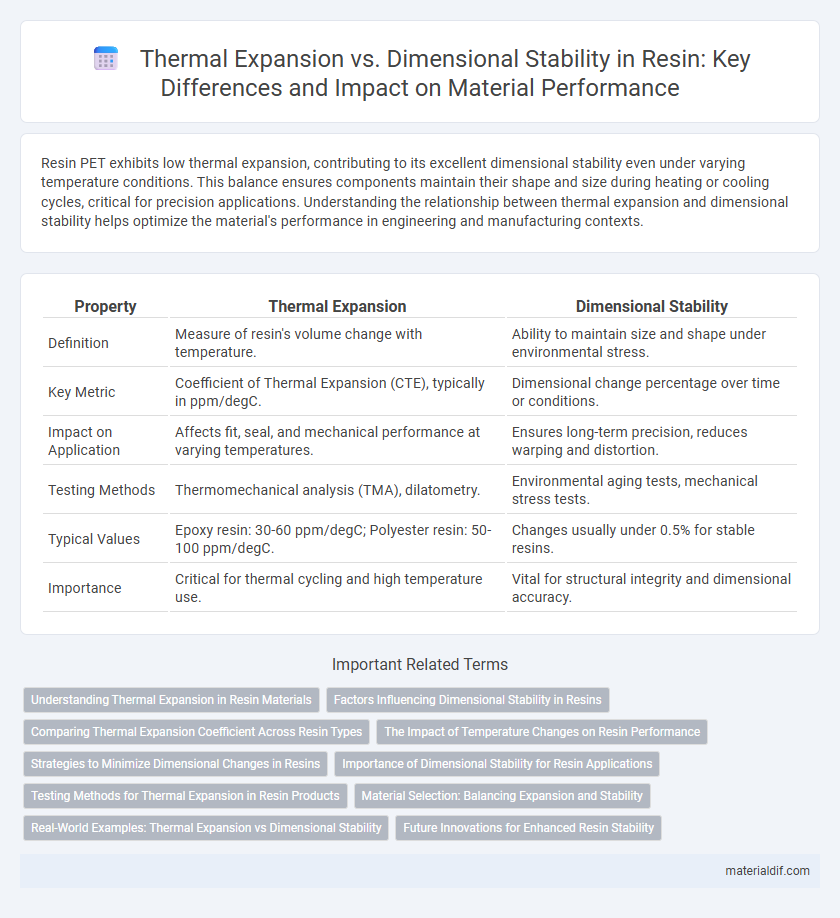

Resin PET exhibits low thermal expansion, contributing to its excellent dimensional stability even under varying temperature conditions. This balance ensures components maintain their shape and size during heating or cooling cycles, critical for precision applications. Understanding the relationship between thermal expansion and dimensional stability helps optimize the material's performance in engineering and manufacturing contexts.

Table of Comparison

| Property | Thermal Expansion | Dimensional Stability |

|---|---|---|

| Definition | Measure of resin's volume change with temperature. | Ability to maintain size and shape under environmental stress. |

| Key Metric | Coefficient of Thermal Expansion (CTE), typically in ppm/degC. | Dimensional change percentage over time or conditions. |

| Impact on Application | Affects fit, seal, and mechanical performance at varying temperatures. | Ensures long-term precision, reduces warping and distortion. |

| Testing Methods | Thermomechanical analysis (TMA), dilatometry. | Environmental aging tests, mechanical stress tests. |

| Typical Values | Epoxy resin: 30-60 ppm/degC; Polyester resin: 50-100 ppm/degC. | Changes usually under 0.5% for stable resins. |

| Importance | Critical for thermal cycling and high temperature use. | Vital for structural integrity and dimensional accuracy. |

Understanding Thermal Expansion in Resin Materials

Thermal expansion in resin materials refers to the tendency of the resin to change its volume or shape when exposed to temperature variations, a critical factor impacting overall dimensional stability. The coefficient of thermal expansion (CTE) measures how much the resin expands per degree of temperature increase, influencing applications where precise dimensions are required. Understanding the interaction between resin composition, temperature range, and thermal cycling is essential for predicting deformation and preventing structural failures in resin-based components.

Factors Influencing Dimensional Stability in Resins

Dimensional stability in resins is primarily influenced by the thermal expansion coefficient, crosslink density, filler content, and environmental conditions such as humidity and temperature fluctuations. High crosslink density reduces molecular mobility, thereby minimizing dimensional changes, while fillers like glass or carbon fibers restrict resin expansion by providing structural reinforcement. Moisture absorption also affects resin stability by causing swelling, which compounds dimensional variability when combined with thermal expansion under fluctuating service environments.

Comparing Thermal Expansion Coefficient Across Resin Types

The thermal expansion coefficient varies significantly among resin types, with epoxy resins generally exhibiting lower values around 30-70 x 10^-6 /degC, indicating superior dimensional stability compared to polyester resins that can reach up to 150 x 10^-6 /degC. Polycarbonate resins show moderate thermal expansion, typically near 65-85 x 10^-6 /degC, balancing flexibility and stability under temperature fluctuations. Understanding these differences is critical for applications requiring precise dimensional control under thermal stress.

The Impact of Temperature Changes on Resin Performance

Resin exhibits thermal expansion, which causes dimensional changes when exposed to temperature fluctuations, directly affecting its performance in precision applications. High thermal expansion can lead to warping, cracking, or loss of structural integrity, compromising the resin's durability and mechanical properties. Maintaining dimensional stability under varying temperatures is crucial for resins used in electronics, aerospace, and automotive components to ensure long-term reliability and functionality.

Strategies to Minimize Dimensional Changes in Resins

Controlling thermal expansion in resins involves integrating fillers such as glass or carbon fibers, which significantly reduce dimensional changes by enhancing the composite's rigidity. Optimizing resin formulations with cross-linking agents improves molecular stability, thereby minimizing distortions caused by temperature fluctuations. Implementing precise curing processes and maintaining uniform cooling rates further contribute to achieving consistent dimensional stability in resin applications.

Importance of Dimensional Stability for Resin Applications

Dimensional stability in resin applications ensures consistent shape and size under temperature fluctuations, crucial for precision components in automotive and aerospace industries. Unlike thermal expansion, which causes material deformation, high dimensional stability prevents warping, maintaining functional integrity and reliability. This property is vital for resins used in electronics, medical devices, and structural parts where exact tolerances and long-term performance are mandatory.

Testing Methods for Thermal Expansion in Resin Products

Thermal expansion in resin products is typically measured using dilatometry, which tracks dimensional changes as temperature varies, ensuring precise assessment of the coefficient of thermal expansion (CTE). Thermomechanical analysis (TMA) offers detailed insights into dimensional stability by applying controlled mechanical force while monitoring expansion under thermal cycling. Dynamic mechanical analysis (DMA) can also evaluate thermal transitions and the impact on resin structural integrity, crucial for predicting performance under thermal stress.

Material Selection: Balancing Expansion and Stability

Selecting resins with low thermal expansion coefficients is critical to maintaining dimensional stability in applications subjected to temperature variations. Materials like epoxy and phenolic resins provide superior stability due to their inherent rigidity and cross-linked structures, minimizing deformation risks. Balancing thermal expansion properties with mechanical and environmental requirements ensures optimal performance and longevity in engineered components.

Real-World Examples: Thermal Expansion vs Dimensional Stability

Resin materials like epoxy and polyurethane exhibit varying degrees of thermal expansion, which can impact the dimensional stability of molded components in automotive or aerospace applications. For instance, epoxy resins used in aircraft composites demonstrate excellent dimensional stability at elevated temperatures, minimizing structural distortion during flight cycles. Conversely, polypropylene resins in automotive parts may experience significant thermal expansion, leading to potential fitment issues and performance degradation under high heat conditions.

Future Innovations for Enhanced Resin Stability

Future innovations in resin technology aim to reduce thermal expansion by integrating nano-fillers and advanced cross-linking agents, significantly improving dimensional stability under temperature fluctuations. Researchers are developing smart resin composites that adapt their microstructure in response to heat, minimizing deformation and enhancing long-term performance. These advancements are expected to expand the application of resins in high-precision industries such as aerospace, electronics, and automotive manufacturing.

Thermal Expansion vs Dimensional Stability Infographic

materialdif.com

materialdif.com