Solventless resin offers a purer, more natural product as it is extracted without the use of chemical solvents, preserving the terpene profile and enhancing flavor and aroma. In contrast, solvent-based resin uses chemicals like butane or propane for extraction, which can leave residues and affect the final product's purity. Choosing solventless resin ensures a cleaner, safer experience with a more robust and authentic taste.

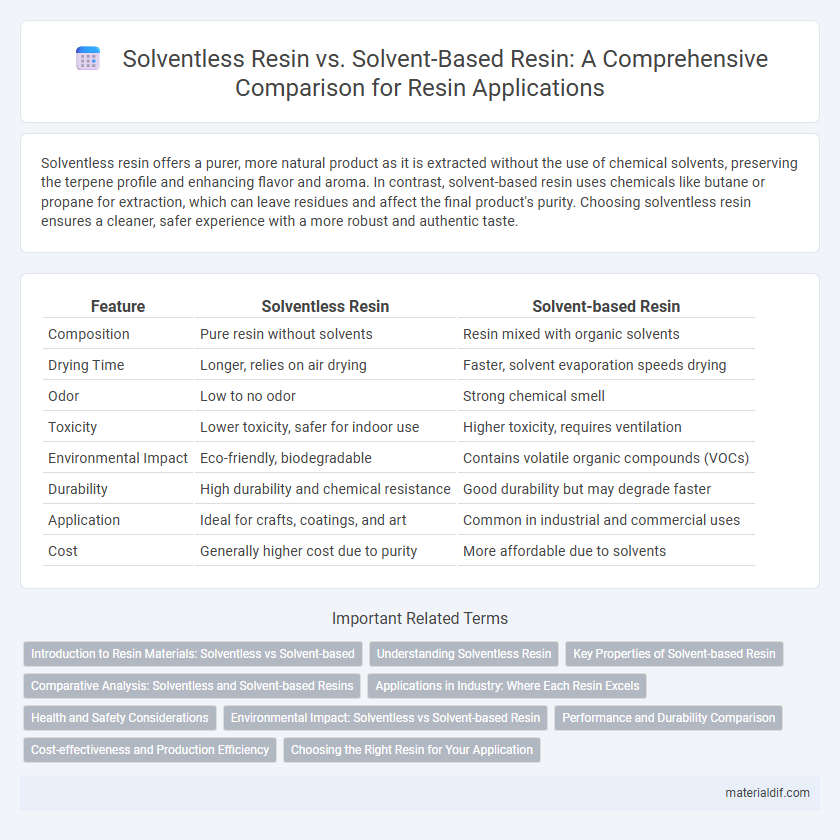

Table of Comparison

| Feature | Solventless Resin | Solvent-based Resin |

|---|---|---|

| Composition | Pure resin without solvents | Resin mixed with organic solvents |

| Drying Time | Longer, relies on air drying | Faster, solvent evaporation speeds drying |

| Odor | Low to no odor | Strong chemical smell |

| Toxicity | Lower toxicity, safer for indoor use | Higher toxicity, requires ventilation |

| Environmental Impact | Eco-friendly, biodegradable | Contains volatile organic compounds (VOCs) |

| Durability | High durability and chemical resistance | Good durability but may degrade faster |

| Application | Ideal for crafts, coatings, and art | Common in industrial and commercial uses |

| Cost | Generally higher cost due to purity | More affordable due to solvents |

Introduction to Resin Materials: Solventless vs Solvent-based

Solventless resin materials eliminate the use of organic solvents, resulting in lower VOC emissions and enhanced environmental safety compared to solvent-based resins. Solvent-based resins rely on solvents to dissolve the polymer matrix, enabling easier application but contributing to higher toxicity and longer drying times. Understanding these fundamental differences guides optimal resin selection for industrial applications emphasizing health, safety, and performance.

Understanding Solventless Resin

Solventless resin is a high-purity extract derived without using chemical solvents, preserving the natural terpene profile and cannabinoid content for enhanced flavor and potency. This type of resin undergoes mechanical extraction methods such as rosin pressing or dry sifting, ensuring a cleaner product free from residual solvents often found in solvent-based resins. Understanding solventless resin is crucial for consumers seeking a more natural and environmentally friendly option with superior safety and quality standards in cannabis concentrates.

Key Properties of Solvent-based Resin

Solvent-based resin is characterized by its superior adhesion and flexibility due to the presence of volatile organic compounds that enhance resin flow and penetration. These resins typically offer faster drying times and form a robust, durable finish resistant to moisture and chemical exposure. However, their application releases solvents, requiring careful handling and ventilation to mitigate environmental and health impacts.

Comparative Analysis: Solventless and Solvent-based Resins

Solventless resins contain no volatile organic compounds (VOCs), offering higher purity, better chemical stability, and reduced environmental impact compared to solvent-based resins. Solvent-based resins typically have lower viscosity for easier application but pose greater health risks and require longer curing times due to solvent evaporation. Choosing between solventless and solvent-based resins depends on application requirements such as durability, environmental safety, and processing conditions.

Applications in Industry: Where Each Resin Excels

Solventless resin excels in electronics and automotive industries due to its high purity, low VOC emissions, and superior adhesion without the risk of solvent residues, making it ideal for sensitive components and environmentally regulated manufacturing. Solvent-based resin is preferred in coatings, adhesives, and composite manufacturing where fast drying times and strong penetration into substrates enhance durability and finish quality. Each resin type's application depends on industry-specific requirements for environmental safety, curing speed, and material compatibility.

Health and Safety Considerations

Solventless resin eliminates volatile organic compounds (VOCs), significantly reducing inhalation risks and respiratory irritation associated with solvent-based alternatives. The absence of harmful solvents minimizes flammability hazards and environmental pollutants, enhancing workplace safety. Careful handling of solvent-based resins is crucial due to their chemical toxicity and potential for skin absorption, necessitating comprehensive protective measures.

Environmental Impact: Solventless vs Solvent-based Resin

Solventless resin significantly reduces environmental impact by eliminating volatile organic compounds (VOCs), which are prevalent in solvent-based resins and contribute to air pollution and health risks. Manufacturing and application of solventless resins generate fewer hazardous emissions and waste, promoting safer air quality and reduced ecological footprint. This eco-friendly alternative supports sustainable practices by minimizing chemical solvents that typically require rigorous disposal procedures and energy-intensive treatment.

Performance and Durability Comparison

Solventless resin offers superior durability and performance due to its higher molecular weight and fewer volatile organic compounds, resulting in enhanced chemical resistance and longer-lasting adhesion. Solvent-based resin, while easier to apply, tends to have weaker bond strength and is more prone to degradation over time because solvents evaporate, causing shrinkage and brittleness. In industrial applications where long-term wear and chemical exposure are critical, solventless resin provides a more robust and reliable solution.

Cost-effectiveness and Production Efficiency

Solventless resin offers superior cost-effectiveness by eliminating the need for expensive solvents, reducing material costs and waste disposal expenses. Production efficiency improves with solventless resin due to faster curing times and simplified handling processes, minimizing downtime and energy consumption. In contrast, solvent-based resins require additional solvent recovery or ventilation systems, increasing both operational complexity and production costs.

Choosing the Right Resin for Your Application

Solventless resin offers superior durability and environmental benefits by eliminating harmful solvents, making it ideal for applications requiring strong adhesion and low VOC emissions. Solvent-based resin provides ease of application and faster curing times, suited for projects where quick turnaround is critical. Selecting the right resin depends on factors like application surface, environmental regulations, and desired performance characteristics.

Solventless Resin vs Solvent-based Resin Infographic

materialdif.com

materialdif.com