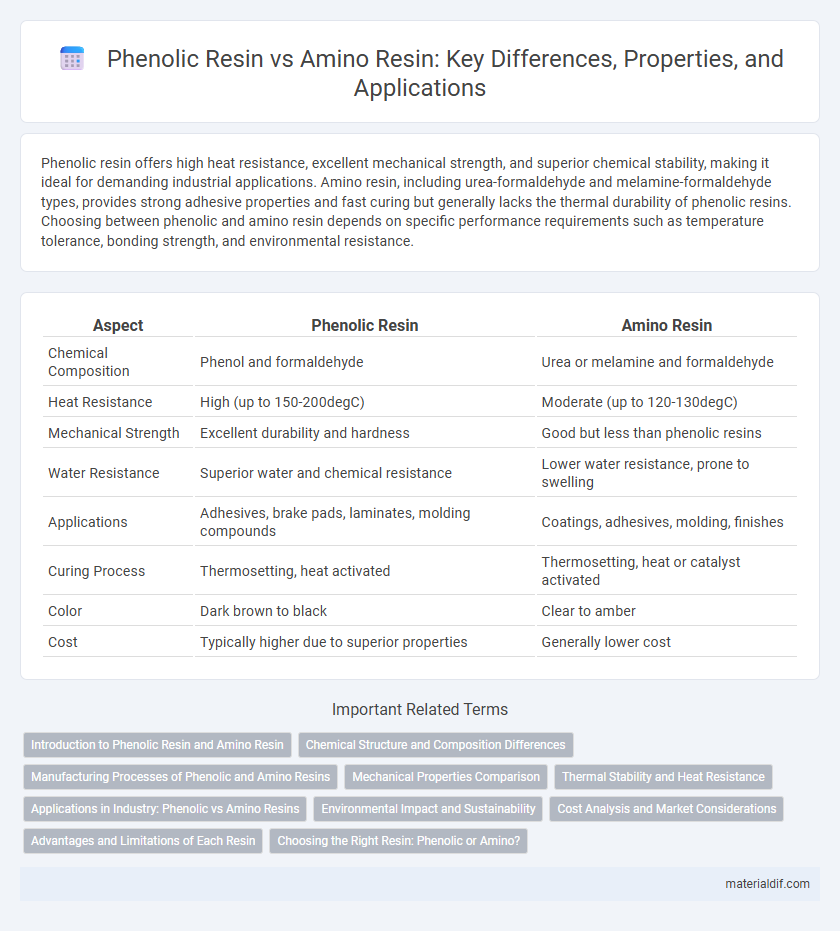

Phenolic resin offers high heat resistance, excellent mechanical strength, and superior chemical stability, making it ideal for demanding industrial applications. Amino resin, including urea-formaldehyde and melamine-formaldehyde types, provides strong adhesive properties and fast curing but generally lacks the thermal durability of phenolic resins. Choosing between phenolic and amino resin depends on specific performance requirements such as temperature tolerance, bonding strength, and environmental resistance.

Table of Comparison

| Aspect | Phenolic Resin | Amino Resin |

|---|---|---|

| Chemical Composition | Phenol and formaldehyde | Urea or melamine and formaldehyde |

| Heat Resistance | High (up to 150-200degC) | Moderate (up to 120-130degC) |

| Mechanical Strength | Excellent durability and hardness | Good but less than phenolic resins |

| Water Resistance | Superior water and chemical resistance | Lower water resistance, prone to swelling |

| Applications | Adhesives, brake pads, laminates, molding compounds | Coatings, adhesives, molding, finishes |

| Curing Process | Thermosetting, heat activated | Thermosetting, heat or catalyst activated |

| Color | Dark brown to black | Clear to amber |

| Cost | Typically higher due to superior properties | Generally lower cost |

Introduction to Phenolic Resin and Amino Resin

Phenolic resin, a synthetic polymer derived from phenol and formaldehyde, is known for its exceptional thermal stability, chemical resistance, and mechanical strength, making it ideal for applications such as adhesives, coatings, and molded products. Amino resin, formed by the reaction of formaldehyde with amino compounds like urea or melamine, offers excellent hardness, gloss, and water resistance, widely used in laminates, adhesives, and surface finishes. Both resins serve distinct industrial purposes due to their unique chemical structures and performance characteristics, influencing their selection in manufacturing processes.

Chemical Structure and Composition Differences

Phenolic resins are composed of phenol and formaldehyde, forming a three-dimensional network through methylene bridges that provide high thermal stability and chemical resistance. Amino resins, such as urea-formaldehyde and melamine-formaldehyde, consist of amino groups attached to a formaldehyde backbone, resulting in faster curing times and improved surface hardness but lower thermal resistance compared to phenolic resins. The primary chemical difference lies in phenolic resin's aromatic ring structure versus amino resin's nitrogen-containing groups, which affect their mechanical and chemical performance in industrial applications.

Manufacturing Processes of Phenolic and Amino Resins

Phenolic resins are manufactured through the condensation reaction of phenol with formaldehyde under acidic or basic conditions, resulting in a network polymer known for high thermal stability and chemical resistance. Amino resins, primarily urea-formaldehyde or melamine-formaldehyde types, are produced by reacting formaldehyde with amino compounds such as urea or melamine, typically using controlled polymerization processes to achieve desirable bonding and curing properties. The manufacturing of phenolic resins generally involves longer curing times and higher temperature requirements compared to amino resins, which cure faster and offer better color retention and surface finish.

Mechanical Properties Comparison

Phenolic resin exhibits superior mechanical strength, high heat resistance, and excellent dimensional stability compared to amino resin, making it ideal for industrial applications requiring durability. Amino resin, while offering good hardness and surface finish, tends to have lower impact resistance and flexibility. The enhanced thermal and mechanical properties of phenolic resin contribute to its frequent use in molds, laminates, and adhesives where mechanical stress is a critical factor.

Thermal Stability and Heat Resistance

Phenolic resin exhibits superior thermal stability and heat resistance compared to amino resin, withstanding temperatures up to 150-250degC without significant degradation, making it ideal for high-temperature applications. Amino resins, such as urea-formaldehyde and melamine-formaldehyde, typically offer lower thermal stability, tolerating temperatures up to approximately 120-150degC before losing structural integrity. The enhanced heat resistance of phenolic resins results from their highly cross-linked aromatic structure, which provides excellent resistance to thermal decomposition and oxidation.

Applications in Industry: Phenolic vs Amino Resins

Phenolic resins are widely used in industries requiring high thermal stability and mechanical strength, such as aerospace, automotive brake systems, and electrical insulation. Amino resins, including urea-formaldehyde and melamine-formaldehyde resins, excel in applications like wood adhesives, laminates, and molding compounds due to their superior hardness and gloss. Both resin types offer tailored chemical properties, making phenolic resins ideal for heat-resistant components, while amino resins provide excellent surface finishes and durability in consumer goods.

Environmental Impact and Sustainability

Phenolic resin, derived from phenol and formaldehyde, offers superior thermal stability and chemical resistance but raises environmental concerns due to formaldehyde emissions and non-biodegradability. Amino resin, typically formed from urea or melamine and formaldehyde, has lower emissions but still poses issues related to formaldehyde release and limited recycling potential. Both resins require advancements in green chemistry and alternative raw materials to improve sustainability and reduce ecological footprints in industrial applications.

Cost Analysis and Market Considerations

Phenolic resin generally offers a lower cost compared to amino resin due to its simpler production process and abundant raw materials, making it a preferred choice for large-scale industrial applications such as automotive brakes and circuit boards. Amino resin, including urea-formaldehyde and melamine-formaldehyde types, commands higher prices driven by superior properties like enhanced hardness, water resistance, and aesthetic finishes, which suits consumer goods and decorative laminates. Market trends indicate a steady demand for phenolic resin in sectors prioritizing cost-efficiency, while amino resin maintains niche leadership in premium products balancing performance and price.

Advantages and Limitations of Each Resin

Phenolic resins offer high thermal stability, excellent chemical resistance, and superior mechanical strength, making them ideal for high-temperature applications and durable composites. Amino resins provide good adhesion, ease of molding, and low cure temperatures, which suit decorative laminates and adhesives but tend to have lower moisture resistance and reduced durability compared to phenolic resins. Limitations of phenolic resins include brittleness and limited flexibility, while amino resins may release formaldehyde and exhibit decreased performance under prolonged exposure to heat and moisture.

Choosing the Right Resin: Phenolic or Amino?

Phenolic resin offers superior heat resistance and mechanical strength, making it ideal for high-temperature applications such as automotive components and electrical insulators. Amino resin provides excellent adhesion and water resistance, commonly used in laminates, adhesives, and molding compounds where durability and surface finish are critical. Selecting between phenolic and amino resin depends on the specific performance requirements, environmental exposure, and end-use application to ensure optimal material performance and cost efficiency.

Phenolic Resin vs Amino Resin Infographic

materialdif.com

materialdif.com