The shrinkage rate and flow rate in resin PET are critical factors influencing product quality and manufacturing efficiency. A higher flow rate can lead to lower shrinkage by ensuring uniform filling and reducing internal stresses during cooling. Optimizing these parameters balances dimensional accuracy with mechanical properties, preventing defects such as warping and voids.

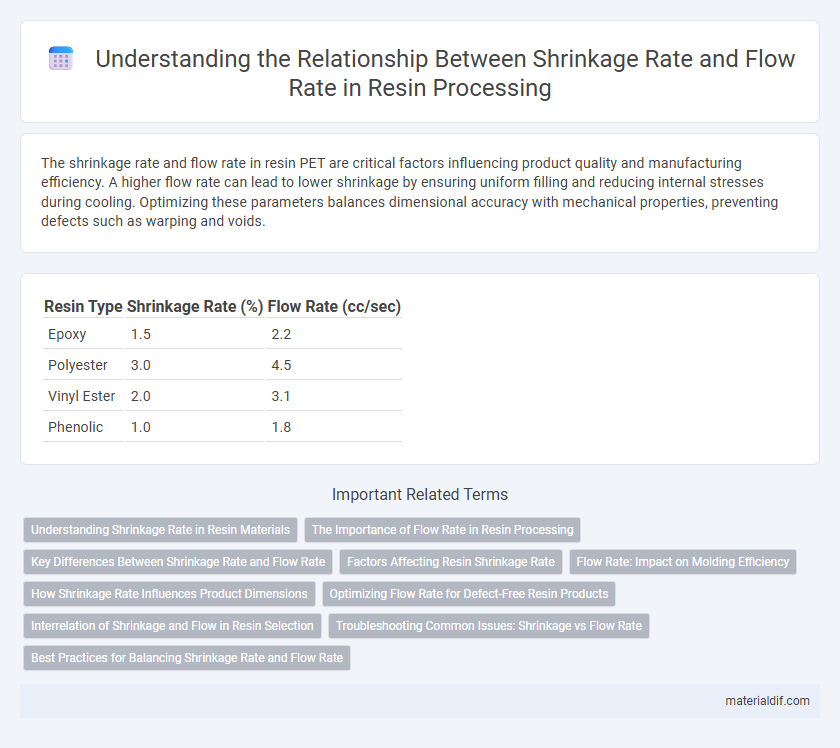

Table of Comparison

| Resin Type | Shrinkage Rate (%) | Flow Rate (cc/sec) |

|---|---|---|

| Epoxy | 1.5 | 2.2 |

| Polyester | 3.0 | 4.5 |

| Vinyl Ester | 2.0 | 3.1 |

| Phenolic | 1.0 | 1.8 |

Understanding Shrinkage Rate in Resin Materials

Shrinkage rate in resin materials refers to the dimensional reduction that occurs during the curing or cooling process, significantly impacting the final product quality and structural integrity. Accurate measurement of shrinkage rate helps in predicting material behavior and compensating for potential defects in mold design and processing parameters. Understanding the relationship between shrinkage rate and flow rate is essential for optimizing mold filling, ensuring uniform material distribution, and preventing internal stresses or warping in resin-based components.

The Importance of Flow Rate in Resin Processing

Flow rate critically influences resin processing by directly affecting shrinkage rate and final product quality. Precise control of flow rate ensures uniform resin distribution, minimizing internal stresses and reducing dimensional changes during curing. Optimizing flow rate enhances material performance and consistency, crucial for high-precision applications in composite manufacturing.

Key Differences Between Shrinkage Rate and Flow Rate

Shrinkage rate measures the percentage reduction in resin volume as it cools and solidifies, directly affecting the final dimensions and structural integrity of molded parts. Flow rate indicates the speed at which resin moves through the mold during injection, influencing fill time and defect formation like weld lines or air traps. Understanding the key differences helps optimize processing parameters to balance dimensional accuracy and efficient mold filling.

Factors Affecting Resin Shrinkage Rate

Resin shrinkage rate is influenced by factors such as curing temperature, resin formulation, and filler content, which directly impact the polymerization process and material contraction. Higher flow rates can lead to uneven resin distribution, resulting in inconsistent shrinkage patterns and potential defects in the final product. Optimizing the balance between flow rate and curing parameters ensures minimal shrinkage and improved dimensional stability in resin applications.

Flow Rate: Impact on Molding Efficiency

High flow rate in resin significantly enhances molding efficiency by reducing cycle time and ensuring uniform cavity filling. Optimal flow rate minimizes defects such as voids and incomplete fills, directly impacting the quality of the final molded product. Balancing flow rate with resin viscosity is crucial to achieving maximum production speed without compromising part integrity.

How Shrinkage Rate Influences Product Dimensions

Shrinkage rate directly impacts product dimensions by causing a reduction in size from the mold to the final cured form, leading to potential dimensional inaccuracies. Higher shrinkage rates often result in greater deformation, warping, or internal stresses within resin products. Precise control of flow rate during resin injection can mitigate shrinkage effects by ensuring uniform material distribution and consistent curing, thereby preserving intended dimensions.

Optimizing Flow Rate for Defect-Free Resin Products

Optimizing flow rate in resin processing is crucial to minimize shrinkage rate and achieve defect-free products. A controlled flow rate ensures uniform material distribution, reducing internal stresses that cause warping and dimensional inaccuracies. Precise adjustment of flow parameters enhances the structural integrity and surface finish of resin-based components.

Interrelation of Shrinkage and Flow in Resin Selection

Shrinkage rate in resin directly impacts its flow rate during molding, influencing the final product's dimensional accuracy and surface quality. High-flow resins tend to exhibit lower shrinkage rates, reducing internal stresses and warpage, which is critical for precision applications. Understanding the interrelation of shrinkage and flow informs optimal resin selection, balancing processability with mechanical performance demands.

Troubleshooting Common Issues: Shrinkage vs Flow Rate

High shrinkage rates in resin can lead to warping and dimensional inaccuracies, often caused by insufficient flow rates during molding. Increasing the flow rate improves material filling, reducing voids and minimizing shrinkage defects by ensuring uniform resin distribution. Monitoring and optimizing the balance between shrinkage rate and flow rate is essential for achieving precise part quality and minimizing post-processing issues.

Best Practices for Balancing Shrinkage Rate and Flow Rate

Optimizing resin shrinkage rate and flow rate requires precise temperature control and resin viscosity adjustments to maintain dimensional accuracy and prevent defects. Employing rheological analysis and mold flow simulations helps balance shrinkage while ensuring consistent filling and curing. Selecting resins with tailored molecular weights and additives further refines flow characteristics to minimize internal stresses and warpage.

Shrinkage Rate vs Flow Rate Infographic

materialdif.com

materialdif.com