Acrylic resin offers superior weather resistance and clarity, making it ideal for outdoor applications and high-gloss finishes. Alkyd resin provides excellent adhesion and flexibility, commonly used in oil-based paints and primers for its durability and ease of use. Choosing between acrylic and alkyd resin depends on the specific requirements of the project, such as drying time, surface type, and environmental exposure.

Table of Comparison

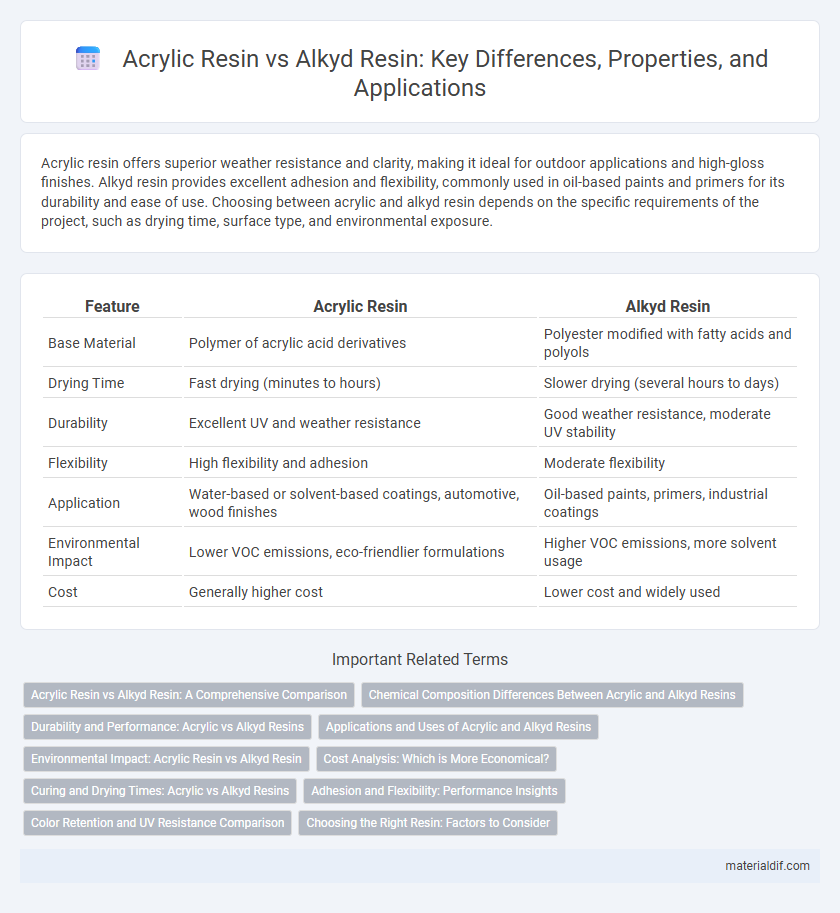

| Feature | Acrylic Resin | Alkyd Resin |

|---|---|---|

| Base Material | Polymer of acrylic acid derivatives | Polyester modified with fatty acids and polyols |

| Drying Time | Fast drying (minutes to hours) | Slower drying (several hours to days) |

| Durability | Excellent UV and weather resistance | Good weather resistance, moderate UV stability |

| Flexibility | High flexibility and adhesion | Moderate flexibility |

| Application | Water-based or solvent-based coatings, automotive, wood finishes | Oil-based paints, primers, industrial coatings |

| Environmental Impact | Lower VOC emissions, eco-friendlier formulations | Higher VOC emissions, more solvent usage |

| Cost | Generally higher cost | Lower cost and widely used |

Acrylic Resin vs Alkyd Resin: A Comprehensive Comparison

Acrylic resin offers superior UV resistance and color retention compared to alkyd resin, making it ideal for exterior applications requiring long-term durability. Alkyd resin provides excellent adhesion and flexibility, often preferred for interior surfaces due to its slower drying time and richer gloss. The choice between acrylic and alkyd resin depends on environmental exposure, desired finish, and maintenance requirements.

Chemical Composition Differences Between Acrylic and Alkyd Resins

Acrylic resins are primarily composed of polymethyl methacrylate (PMMA) or other acrylic esters derived from acrylic acid, resulting in a polymer with high transparency, UV resistance, and chemical stability. Alkyd resins consist of polyester chains formed from polyols, dibasic acids, and fatty acids or oils, creating a structure that provides excellent adhesion and flexibility but lower UV resistance compared to acrylics. The fundamental chemical difference lies in acrylic resins being based on acrylic monomers with ester linkages, whereas alkyd resins are modified polyesters incorporating fatty acid components, influencing their respective performance in coatings and adhesives.

Durability and Performance: Acrylic vs Alkyd Resins

Acrylic resins offer superior durability with excellent UV resistance, maintaining color and structural integrity over time, making them ideal for outdoor applications. Alkyd resins provide strong adhesion and hardness but tend to yellow and degrade faster under prolonged sunlight exposure. Performance-wise, acrylic resins outperform alkyd in flexibility and weather resistance, resulting in longer-lasting coatings for demanding environments.

Applications and Uses of Acrylic and Alkyd Resins

Acrylic resins are extensively used in automotive coatings, adhesives, and high-performance paints due to their excellent weather resistance and clarity, making them ideal for outdoor applications and industrial finishes. Alkyd resins find widespread use in architectural coatings, wood finishes, and metal primers, valued for their good adhesion, flexibility, and cost-effectiveness in interior and exterior applications. Both resins are integral to manufacturing durable coatings but differ in properties that tailor them to specific industrial and decorative purposes.

Environmental Impact: Acrylic Resin vs Alkyd Resin

Acrylic resin exhibits lower volatile organic compound (VOC) emissions compared to alkyd resin, significantly reducing air pollution and health hazards during application. Alkyd resin relies on petroleum-based solvents, which contribute to higher carbon footprints and longer curing times, increasing energy consumption and environmental burden. Biodegradability of acrylic resins further enhances their eco-friendliness, making them preferable for sustainable coatings and paints.

Cost Analysis: Which is More Economical?

Acrylic resin typically commands a higher price due to its superior durability, UV resistance, and faster drying time, making it a cost-effective choice for long-term applications despite the initial investment. Alkyd resin, on the other hand, offers a more affordable upfront cost but may incur additional maintenance expenses over time due to its slower drying and lower weather resistance. When considering the entire lifecycle cost, acrylic resin often proves more economical for projects requiring longevity and reduced upkeep.

Curing and Drying Times: Acrylic vs Alkyd Resins

Acrylic resin typically cures faster than alkyd resin, often drying to the touch within 30 minutes to 1 hour and fully curing in 24 hours, while alkyd resin may take 6 to 8 hours to dry and several days to fully cure due to its oil-based composition. The rapid curing time of acrylic resins makes them suitable for projects requiring quick turnaround, whereas alkyd resins provide a durable finish but require longer handling and drying periods. Temperature, humidity, and thickness of application significantly influence the drying and curing rates for both resin types.

Adhesion and Flexibility: Performance Insights

Acrylic resin exhibits superior adhesion to a wide range of surfaces, ensuring long-lasting durability in coatings and adhesives. It maintains excellent flexibility over time, resisting cracking and peeling under varying environmental conditions. Alkyd resin offers good adhesion but is generally less flexible, making it more prone to brittleness and potential surface damage during expansion or contraction.

Color Retention and UV Resistance Comparison

Acrylic resin exhibits superior color retention and UV resistance compared to alkyd resin, maintaining vibrant hues and structural integrity over prolonged exposure to sunlight. Alkyd resin tends to yellow and degrade faster under UV radiation, resulting in diminished aesthetic appeal and shorter lifespan. These properties make acrylic resin more suitable for applications demanding long-term durability and color stability in outdoor environments.

Choosing the Right Resin: Factors to Consider

Choosing the right resin depends on application requirements such as drying time, durability, and finish quality. Acrylic resin offers superior UV resistance and faster drying, ideal for outdoor use and vibrant color retention. Alkyd resin provides excellent adhesion and flexibility, making it suitable for metal surfaces and areas needing robust corrosion protection.

Acrylic resin vs Alkyd resin Infographic

materialdif.com

materialdif.com