Bisphenol-A resin offers excellent mechanical strength and chemical resistance, making it ideal for automotive and electrical applications. Bisphenol-F resin provides superior thermal stability and lower viscosity, enhancing processing efficiency and performance in high-temperature environments. Selecting between Bisphenol-A and Bisphenol-F resins depends on the specific application requirements, balancing factors such as durability, heat resistance, and ease of processing.

Table of Comparison

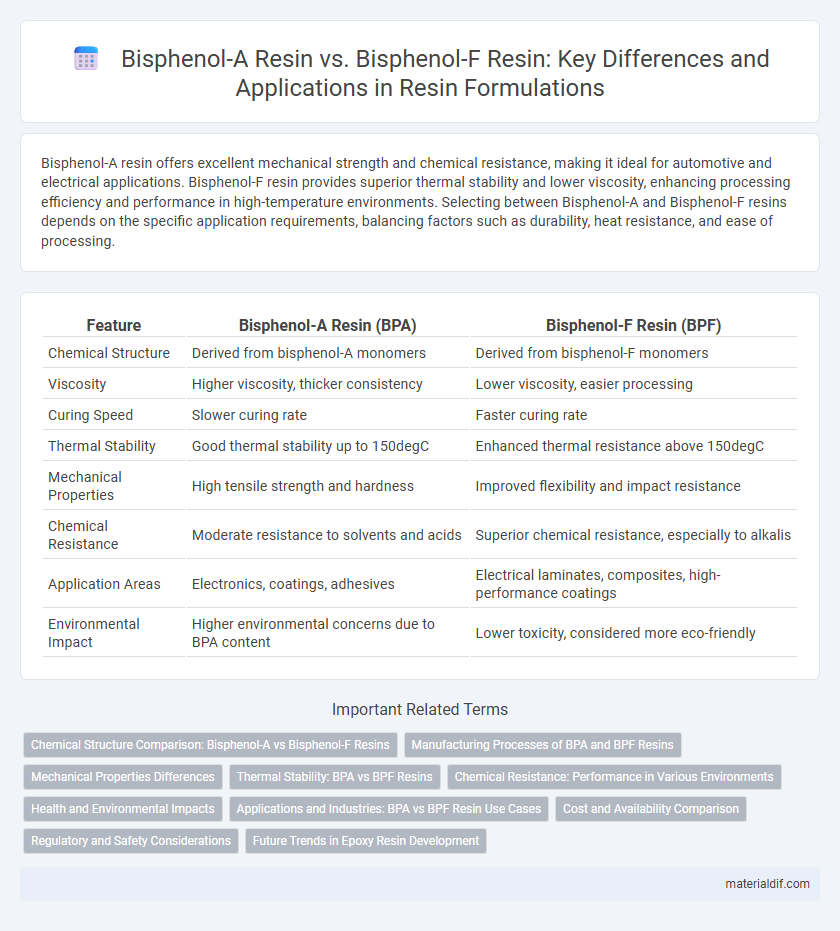

| Feature | Bisphenol-A Resin (BPA) | Bisphenol-F Resin (BPF) |

|---|---|---|

| Chemical Structure | Derived from bisphenol-A monomers | Derived from bisphenol-F monomers |

| Viscosity | Higher viscosity, thicker consistency | Lower viscosity, easier processing |

| Curing Speed | Slower curing rate | Faster curing rate |

| Thermal Stability | Good thermal stability up to 150degC | Enhanced thermal resistance above 150degC |

| Mechanical Properties | High tensile strength and hardness | Improved flexibility and impact resistance |

| Chemical Resistance | Moderate resistance to solvents and acids | Superior chemical resistance, especially to alkalis |

| Application Areas | Electronics, coatings, adhesives | Electrical laminates, composites, high-performance coatings |

| Environmental Impact | Higher environmental concerns due to BPA content | Lower toxicity, considered more eco-friendly |

Chemical Structure Comparison: Bisphenol-A vs Bisphenol-F Resins

Bisphenol-A resin features a chemical structure with two phenol groups connected by a propane bridge, leading to higher rigidity and thermal stability in polymer applications. Bisphenol-F resin differs by having a methylene bridge linking the phenol units, resulting in enhanced flexibility and better adhesion properties. These structural variations affect the resins' viscosity, cure rates, and overall mechanical performance in coatings and composite materials.

Manufacturing Processes of BPA and BPF Resins

Bisphenol-A (BPA) resin is primarily manufactured through the acid-catalyzed condensation of acetone with phenol, resulting in a thermosetting polymer widely used in epoxy resins and polycarbonate plastics. Bisphenol-F (BPF) resin production involves the reaction of phenol with formaldehyde under acidic or basic conditions, forming a resin with enhanced thermal stability and chemical resistance compared to BPA-based resins. The different manufacturing processes of BPA and BPF resins directly influence their molecular structure, performance characteristics, and application suitability in coatings, adhesives, and composite materials.

Mechanical Properties Differences

Bisphenol-A resin typically offers higher tensile strength and better impact resistance, making it suitable for applications requiring durability under stress. Bisphenol-F resin generally provides superior chemical resistance and improved dimensional stability, but with slightly lower mechanical strength compared to Bisphenol-A. These differences influence the choice of resin based on specific performance requirements in engineering and manufacturing.

Thermal Stability: BPA vs BPF Resins

Bisphenol-A (BPA) resin typically exhibits higher thermal stability compared to Bisphenol-F (BPF) resin, making it suitable for applications involving prolonged exposure to elevated temperatures. The molecular structure of BPA resins provides enhanced resistance to thermal degradation, withstanding temperatures often above 200degC without significant loss of mechanical properties. In contrast, BPF resins show slightly lower thermal resistance but offer improved flexibility and chemical resistance in certain industrial uses.

Chemical Resistance: Performance in Various Environments

Bisphenol-A resin exhibits strong chemical resistance, particularly against acids, alkalis, and solvents, making it suitable for applications in harsh industrial environments. Bisphenol-F resin offers enhanced resistance to water and improved durability in alkaline conditions, providing superior performance in environments with prolonged moisture exposure. Both resins demonstrate excellent thermal stability, but Bisphenol-F resin is often preferred for coatings and adhesives requiring higher resistance to chemical degradation.

Health and Environmental Impacts

Bisphenol-A (BPA) resin has been linked to endocrine disruption and potential reproductive health risks, prompting regulatory restrictions in many regions. In contrast, Bisphenol-F (BPF) resin offers lower estrogenic activity, reducing some toxicological concerns, but still presents environmental persistence challenges. Both resins contribute to microplastic pollution, necessitating advancements in sustainable resin alternatives and improved waste management strategies.

Applications and Industries: BPA vs BPF Resin Use Cases

Bisphenol-A (BPA) resin is widely used in producing polycarbonate plastics and epoxy resins for automotive parts, electronics, and protective coatings due to its high strength and clarity. Bisphenol-F (BPF) resin is preferred in applications requiring superior chemical resistance and thermal stability, such as in adhesives, coatings, and electrical insulation in the aerospace and chemical industries. Both resins serve critical roles in manufacturing, with BPA dominating consumer goods and BPF favored in more demanding industrial environments.

Cost and Availability Comparison

Bisphenol-A resin is generally more cost-effective and widely available due to its extensive industrial production and established supply chains. Bisphenol-F resin tends to have higher prices, reflecting its specialized applications and limited manufacturing facilities. Availability of Bisphenol-A resin is consistent across global markets, whereas Bisphenol-F resin may face regional supply constraints affecting procurement timelines.

Regulatory and Safety Considerations

Bisphenol-A (BPA) resin faces stricter regulatory scrutiny due to its classification as a potential endocrine disruptor, leading to limitations in food contact materials and toys in regions like the EU and California. Bisphenol-F (BPF) resin is gaining preference for applications requiring safer chemical profiles, as it exhibits lower estrogenic activity and reduced leaching compared to BPA. Both resins are subject to ongoing safety evaluations, but BPF resin aligns better with current regulatory trends seeking alternatives with minimized human health risks.

Future Trends in Epoxy Resin Development

Bisphenol-A (BPA) and Bisphenol-F (BPF) resins remain foundational in epoxy resin technology, with BPF gaining traction due to its lower viscosity and enhanced chemical resistance, catering to trending demands for durable, environmentally friendly coatings. Advances in bio-based and low-emission curing agents are steering future epoxy resin formulations toward improved sustainability and performance, aligning with stricter environmental regulations and circular economy goals. Emerging research emphasizes hybrid resin systems combining BPA and BPF derivatives to optimize mechanical properties and thermal stability for high-tech applications in aerospace and electronics.

Bisphenol-A Resin vs Bisphenol-F Resin Infographic

materialdif.com

materialdif.com