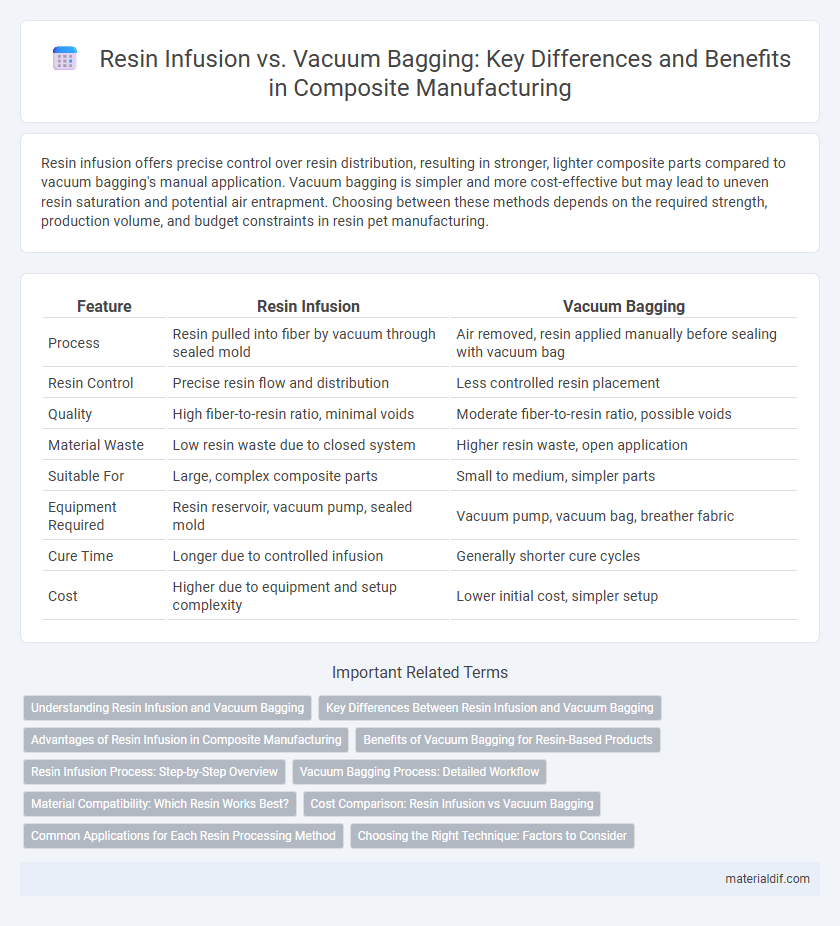

Resin infusion offers precise control over resin distribution, resulting in stronger, lighter composite parts compared to vacuum bagging's manual application. Vacuum bagging is simpler and more cost-effective but may lead to uneven resin saturation and potential air entrapment. Choosing between these methods depends on the required strength, production volume, and budget constraints in resin pet manufacturing.

Table of Comparison

| Feature | Resin Infusion | Vacuum Bagging |

|---|---|---|

| Process | Resin pulled into fiber by vacuum through sealed mold | Air removed, resin applied manually before sealing with vacuum bag |

| Resin Control | Precise resin flow and distribution | Less controlled resin placement |

| Quality | High fiber-to-resin ratio, minimal voids | Moderate fiber-to-resin ratio, possible voids |

| Material Waste | Low resin waste due to closed system | Higher resin waste, open application |

| Suitable For | Large, complex composite parts | Small to medium, simpler parts |

| Equipment Required | Resin reservoir, vacuum pump, sealed mold | Vacuum pump, vacuum bag, breather fabric |

| Cure Time | Longer due to controlled infusion | Generally shorter cure cycles |

| Cost | Higher due to equipment and setup complexity | Lower initial cost, simpler setup |

Understanding Resin Infusion and Vacuum Bagging

Resin infusion and vacuum bagging are advanced composite manufacturing techniques used for creating strong, lightweight parts by saturating fiber reinforcements with resin. Resin infusion involves drawing resin into dry fibers using vacuum pressure, ensuring thorough resin distribution and minimal voids, while vacuum bagging applies vacuum pressure to compact the laminate and remove excess resin and air. Understanding the differences in resin flow control and pressure application is crucial for selecting the optimal method based on part complexity, resin viscosity, and desired mechanical properties.

Key Differences Between Resin Infusion and Vacuum Bagging

Resin infusion involves pulling resin into a dry fiber layup through a sealed vacuum, ensuring thorough saturation and minimal voids, while vacuum bagging involves applying pressure with a vacuum to compact the laminate and squeezing out excess resin. Resin infusion typically results in lighter, stronger composite parts due to better resin control and reduced resin content compared to vacuum bagging, which can lead to resin-rich areas. Key differences include resin flow mechanisms, degree of resin control, and final composite quality, with resin infusion offering superior consistency for high-performance applications.

Advantages of Resin Infusion in Composite Manufacturing

Resin infusion offers superior control over resin distribution, ensuring thorough impregnation of fiber reinforcements and resulting in higher quality composite parts with reduced void content. This process enhances mechanical properties by achieving consistent fiber-to-resin ratios and minimizes resin waste compared to vacuum bagging. Improved environmental safety through reduced emissions and a lower requirement for manual labor also make resin infusion advantageous in composite manufacturing.

Benefits of Vacuum Bagging for Resin-Based Products

Vacuum bagging offers superior consolidation and fiber wet-out for resin-based products, ensuring enhanced structural integrity and reduced void content. This process also allows for precise control over resin distribution, optimizing material usage and improving surface finish quality. The airtight environment created during vacuum bagging minimizes air entrapment and oxidation, resulting in stronger, more durable composite parts.

Resin Infusion Process: Step-by-Step Overview

The resin infusion process begins by laying dry fiber reinforcement onto the mold, followed by sealing it with a vacuum bag to create an airtight environment. A vacuum pump is used to evacuate air and compress the fibers, then resin is introduced through inlet tubing, allowing it to flow and saturate the reinforcement thoroughly under vacuum pressure. The process concludes with curing the resin to form a strong, lightweight composite part with enhanced mechanical properties and reduced void content.

Vacuum Bagging Process: Detailed Workflow

Vacuum bagging is a composite manufacturing process where materials are placed in a mold and sealed under a vacuum bag to remove air and compress the layers. The workflow begins with laying dry fabric reinforcement onto the mold, followed by applying the resin either manually or through pre-impregnated fabrics, then sealing the assembly with a vacuum bag film to create an airtight environment. Once the vacuum pump removes air inside the bag, atmospheric pressure compacts the layers, ensuring resin saturation and eliminating voids, resulting in a strong, lightweight composite part.

Material Compatibility: Which Resin Works Best?

Epoxy resins are highly compatible with resin infusion due to their low viscosity and strong adhesion properties, ensuring thorough fiber wet-out and superior structural integrity. Polyester resins, while less compatible with infusion methods because of higher viscosity, are commonly used in vacuum bagging for their fast curing and cost-effectiveness with compatible fiberglass materials. Vinyl ester resins offer a balance between the two, providing corrosion resistance and compatibility with both infusion and vacuum bagging, especially in marine and automotive composite applications.

Cost Comparison: Resin Infusion vs Vacuum Bagging

Resin infusion generally incurs higher upfront costs due to specialized equipment like vacuum pumps, infusion lines, and resin distribution media, but it offers superior material efficiency and reduced waste, leading to lower long-term expenses. Vacuum bagging requires less initial investment since it uses basic vacuum bags and sealing materials, yet it often results in higher resin consumption and potential rework costs due to inconsistent resin flow. Evaluating total cost of ownership reveals resin infusion's advantage in large-scale, high-performance composite manufacturing despite higher initial outlay.

Common Applications for Each Resin Processing Method

Resin infusion is commonly used in large composite structures such as boat hulls, wind turbine blades, and automotive parts due to its ability to produce high-strength, void-free laminates with consistent resin distribution. Vacuum bagging is ideal for smaller parts and repair work, including aerospace components and sporting goods, where achieving precise control over resin thickness and fiber consolidation is critical. Both methods enhance composite quality but are selected based on part size, complexity, and desired mechanical properties.

Choosing the Right Technique: Factors to Consider

Selecting between resin infusion and vacuum bagging depends on factors such as part complexity, desired mechanical properties, and production volume. Resin infusion offers superior fiber wet-out and reduced void content, ideal for high-performance composites and larger, intricate molds. Vacuum bagging suits simpler geometries and lower-volume runs, providing greater process control and cost-effectiveness for prototype or small-scale production.

Resin Infusion vs Vacuum Bagging Infographic

materialdif.com

materialdif.com