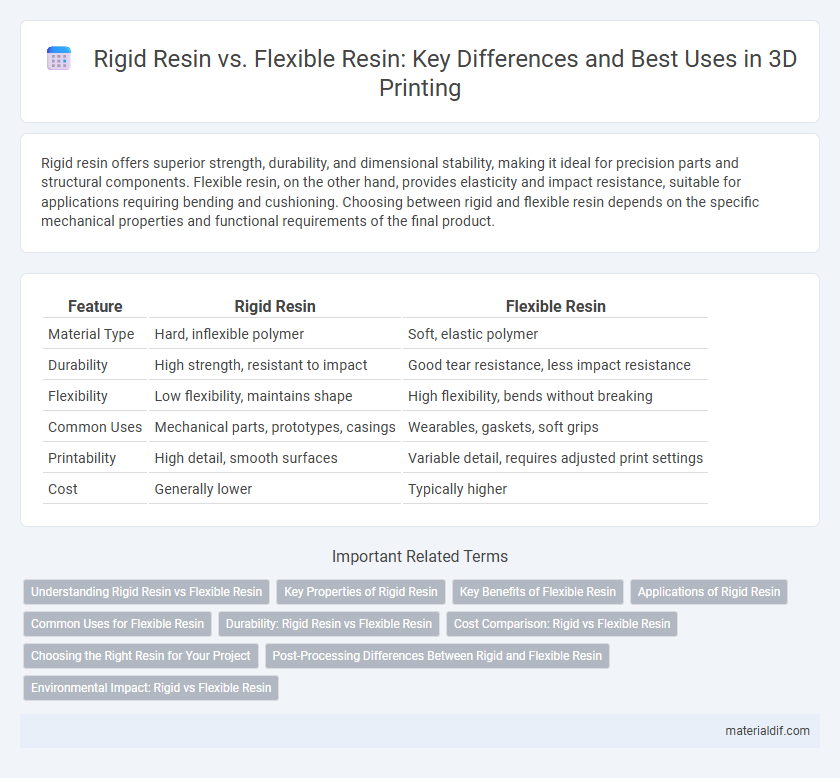

Rigid resin offers superior strength, durability, and dimensional stability, making it ideal for precision parts and structural components. Flexible resin, on the other hand, provides elasticity and impact resistance, suitable for applications requiring bending and cushioning. Choosing between rigid and flexible resin depends on the specific mechanical properties and functional requirements of the final product.

Table of Comparison

| Feature | Rigid Resin | Flexible Resin |

|---|---|---|

| Material Type | Hard, inflexible polymer | Soft, elastic polymer |

| Durability | High strength, resistant to impact | Good tear resistance, less impact resistance |

| Flexibility | Low flexibility, maintains shape | High flexibility, bends without breaking |

| Common Uses | Mechanical parts, prototypes, casings | Wearables, gaskets, soft grips |

| Printability | High detail, smooth surfaces | Variable detail, requires adjusted print settings |

| Cost | Generally lower | Typically higher |

Understanding Rigid Resin vs Flexible Resin

Rigid resin offers high strength and durability, making it ideal for structural applications requiring stiffness and impact resistance. Flexible resin provides elasticity and bendability, suitable for parts that need to absorb shocks or fit complex shapes without cracking. Choosing between rigid resin and flexible resin depends on the specific performance requirements, such as load-bearing capacity versus flexibility in the final product.

Key Properties of Rigid Resin

Rigid resin exhibits high tensile strength, excellent dimensional stability, and superior resistance to heat and chemicals, making it ideal for structural applications. Its low elongation at break ensures minimal deformation under stress, while its hardness provides durability and wear resistance. These properties enable rigid resin to maintain shape integrity and mechanical performance in demanding environments.

Key Benefits of Flexible Resin

Flexible resin offers exceptional elasticity and impact resistance, making it ideal for applications requiring bendable and durable materials. Its superior tear strength and ability to absorb shocks reduce the risk of breakage in prototypes and end-use parts. This resin type enhances product versatility by enabling complex geometries with soft-touch finishes and improved wear resistance.

Applications of Rigid Resin

Rigid resin is extensively used in applications requiring structural strength and dimensional stability, such as automotive parts, industrial machinery components, and consumer electronics housings. Its high tensile strength and resistance to deformation make it ideal for load-bearing parts and precise, durable prototypes in 3D printing. Industries prioritize rigid resin for manufacturing robust tools, mechanical components, and architectural models where rigidity and surface finish quality are critical.

Common Uses for Flexible Resin

Flexible resin is commonly used in applications requiring elasticity and impact resistance, such as wearable devices, seals, gaskets, and soft-touch grips. Its ability to mimic rubber-like properties makes it ideal for prototyping flexible components and producing durable, bendable parts in automotive and consumer electronics industries. Flexible resin is favored for creating customizable, intricate designs where comfort and durability are essential.

Durability: Rigid Resin vs Flexible Resin

Rigid resin offers superior durability with high resistance to impact, wear, and deformation, making it ideal for structural applications requiring long-lasting strength. Flexible resin provides moderate durability, excelling in applications where repeated bending and stress absorption are necessary without cracking. Understanding the balance between stiffness and elasticity helps select the right resin type for durability in specific environmental and mechanical conditions.

Cost Comparison: Rigid vs Flexible Resin

Rigid resin typically costs less per kilogram compared to flexible resin due to simpler manufacturing processes and lower material complexity. Flexible resin, designed for elasticity and durability, often carries a premium price reflecting advanced polymer formulations and additives. Choosing between rigid and flexible resin depends on budget constraints and performance requirements, with rigid resin offering cost efficiency and flexible resin providing specialized functional benefits.

Choosing the Right Resin for Your Project

Rigid resin offers high durability, dimensional stability, and resistance to wear, making it ideal for structural components and precise applications. Flexible resin provides excellent elasticity and impact resistance, suitable for prototypes, wearable devices, and parts requiring bending or compression. Selecting the right resin depends on project demands such as load-bearing capacity, flexibility requirements, and environmental conditions.

Post-Processing Differences Between Rigid and Flexible Resin

Post-processing rigid resin typically involves sanding and curing to achieve a solid, durable finish while maintaining its structural integrity. Flexible resin requires a gentler approach, often needing careful washing and lower-intensity curing to preserve elasticity and prevent brittleness. The differences in post-processing techniques directly impact the final mechanical properties and application suitability of each resin type.

Environmental Impact: Rigid vs Flexible Resin

Rigid resin typically exhibits lower environmental impact due to its durability and recyclability, reducing the need for frequent replacement and minimizing waste. Flexible resin, while offering versatility and lightweight properties, often encounters challenges in recycling processes, potentially leading to higher landfill contributions. The choice between rigid and flexible resin significantly influences resource consumption and end-of-life environmental footprints in various applications.

Rigid Resin vs Flexible Resin Infographic

materialdif.com

materialdif.com