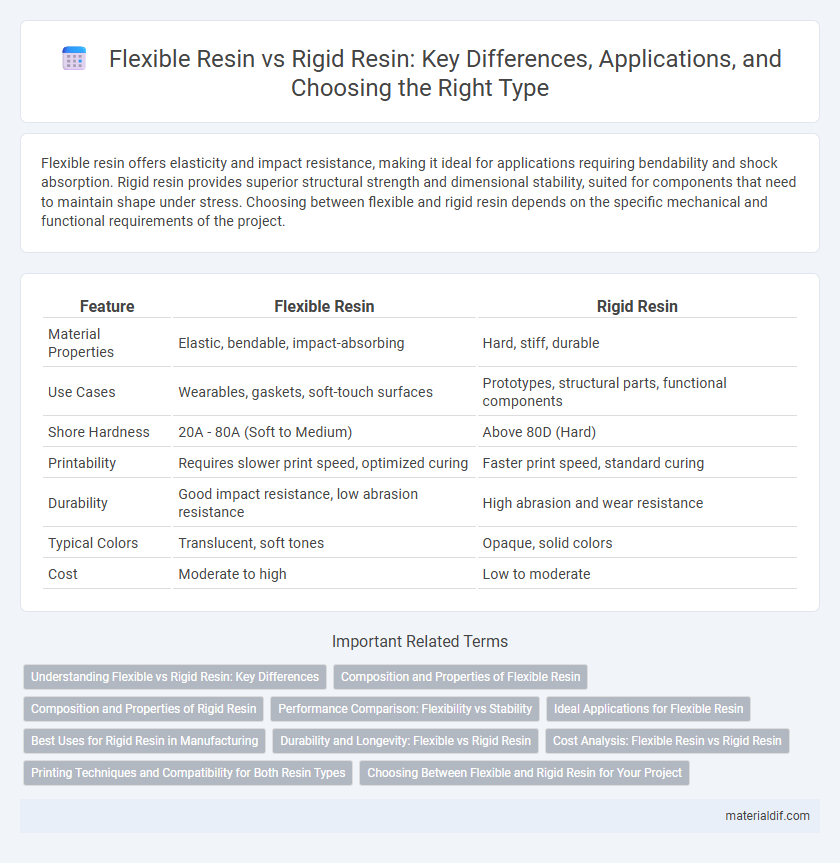

Flexible resin offers elasticity and impact resistance, making it ideal for applications requiring bendability and shock absorption. Rigid resin provides superior structural strength and dimensional stability, suited for components that need to maintain shape under stress. Choosing between flexible and rigid resin depends on the specific mechanical and functional requirements of the project.

Table of Comparison

| Feature | Flexible Resin | Rigid Resin |

|---|---|---|

| Material Properties | Elastic, bendable, impact-absorbing | Hard, stiff, durable |

| Use Cases | Wearables, gaskets, soft-touch surfaces | Prototypes, structural parts, functional components |

| Shore Hardness | 20A - 80A (Soft to Medium) | Above 80D (Hard) |

| Printability | Requires slower print speed, optimized curing | Faster print speed, standard curing |

| Durability | Good impact resistance, low abrasion resistance | High abrasion and wear resistance |

| Typical Colors | Translucent, soft tones | Opaque, solid colors |

| Cost | Moderate to high | Low to moderate |

Understanding Flexible vs Rigid Resin: Key Differences

Flexible resin offers elasticity and impact resistance suitable for applications requiring bendability and shock absorption, while rigid resin provides high structural strength and dimensional stability, ideal for load-bearing and precise components. The chemical composition and curing process determine their mechanical properties, with flexible resin typically incorporating elastomers and rigid resin relying on thermosetting polymers. Choosing between flexible and rigid resin depends on end-use requirements such as flexibility, durability, and environmental resistance.

Composition and Properties of Flexible Resin

Flexible resin typically consists of polyurethane or silicone-based polymers, which impart elasticity and durability suitable for applications requiring bendable or stretchable materials. Its molecular composition includes plasticizers and elastomers that enhance flexibility, impact resistance, and abrasion tolerance, distinguishing it from rigid resin types dominated by thermoset or thermoplastic polymers. These properties make flexible resin ideal for use in seals, gaskets, and wearable devices where resilience under continuous deformation is critical.

Composition and Properties of Rigid Resin

Rigid resin is primarily composed of high-density polymers such as epoxy or polyurethane, which provide a tightly cross-linked molecular structure. This composition results in superior mechanical strength, excellent dimensional stability, and high resistance to heat and chemicals. Its rigidity makes it ideal for applications requiring structural support and durability, unlike flexible resin that incorporates plasticizers for elasticity.

Performance Comparison: Flexibility vs Stability

Flexible resin offers superior elasticity and impact resistance, making it ideal for applications requiring bending and deformation without fracture. Rigid resin provides enhanced dimensional stability and load-bearing strength, suitable for structural parts demanding high stiffness and precise tolerances. Performance comparison highlights that flexible resin excels in shock absorption, while rigid resin ensures long-term durability under stress.

Ideal Applications for Flexible Resin

Flexible resin excels in producing durable, impact-resistant printed parts ideal for wearable devices, soft robotics, and automotive components requiring elasticity. Its ability to withstand repeated bending and compression makes it perfect for prototypes simulating soft tissues or protective covers. Unlike rigid resin, flexible resin offers superior shock absorption and flexibility for functional end-use parts in dynamic environments.

Best Uses for Rigid Resin in Manufacturing

Rigid resin is ideal for manufacturing applications requiring high strength and dimensional stability, such as automotive parts, electronic housings, and structural components. Its ability to withstand mechanical stress and resist deformation makes it suitable for load-bearing and impact-resistant products. Rigid resin's durability and thermal resistance enhance product longevity and performance in demanding industrial environments.

Durability and Longevity: Flexible vs Rigid Resin

Flexible resin offers enhanced durability by absorbing impacts and resisting fractures, making it ideal for applications requiring bendability and repeated stress endurance. Rigid resin, while less forgiving under pressure, provides superior longevity in load-bearing uses due to its high structural stability and resistance to deformation. Material choice depends on balancing flexibility demands with the necessity for long-term strength and wear resistance in specific environments.

Cost Analysis: Flexible Resin vs Rigid Resin

Flexible resin generally incurs higher material costs compared to rigid resin due to its specialized chemical composition and enhanced elasticity properties. Production expenses for flexible resin also tend to be greater, driven by more complex manufacturing processes and extended curing times. In contrast, rigid resin offers cost advantages with lower raw material prices and faster processing, making it a more economical choice for large-scale applications.

Printing Techniques and Compatibility for Both Resin Types

Flexible resin excels in low-force stereolithography techniques like MSLA and DLP, offering high elasticity and impact resistance ideal for wearable or bendable prototypes. Rigid resin is compatible with similar UV-based printing methods but requires precise curing to achieve high strength and dimensional stability suited for functional parts and mechanical components. Both resin types demand calibrated exposure times and post-curing processes to optimize print quality and maximize performance.

Choosing Between Flexible and Rigid Resin for Your Project

Flexible resin offers superior elasticity and impact resistance, making it ideal for projects requiring durability and bendability, such as wearable items or prototypes with moving parts. Rigid resin provides high strength and dimensional stability, perfect for detailed models, mechanical components, and applications needing precise structural integrity. Evaluating project requirements like flexibility, strength, and surface finish helps determine whether flexible or rigid resin best suits your specific use case.

Flexible Resin vs Rigid Resin Infographic

materialdif.com

materialdif.com