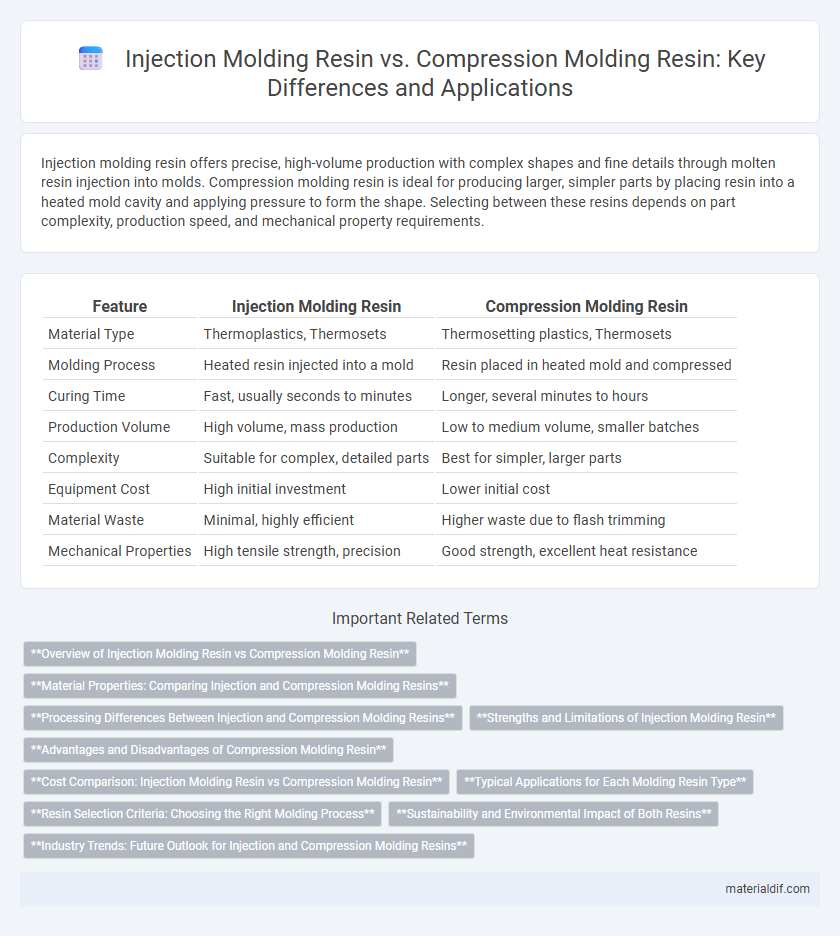

Injection molding resin offers precise, high-volume production with complex shapes and fine details through molten resin injection into molds. Compression molding resin is ideal for producing larger, simpler parts by placing resin into a heated mold cavity and applying pressure to form the shape. Selecting between these resins depends on part complexity, production speed, and mechanical property requirements.

Table of Comparison

| Feature | Injection Molding Resin | Compression Molding Resin |

|---|---|---|

| Material Type | Thermoplastics, Thermosets | Thermosetting plastics, Thermosets |

| Molding Process | Heated resin injected into a mold | Resin placed in heated mold and compressed |

| Curing Time | Fast, usually seconds to minutes | Longer, several minutes to hours |

| Production Volume | High volume, mass production | Low to medium volume, smaller batches |

| Complexity | Suitable for complex, detailed parts | Best for simpler, larger parts |

| Equipment Cost | High initial investment | Lower initial cost |

| Material Waste | Minimal, highly efficient | Higher waste due to flash trimming |

| Mechanical Properties | High tensile strength, precision | Good strength, excellent heat resistance |

Overview of Injection Molding Resin vs Compression Molding Resin

Injection molding resin is engineered for rapid melting and precise flow, ideal for producing complex shapes with high repeatability and fine detail, commonly used with thermoplastics like ABS and polycarbonate. Compression molding resin, typically thermosetting materials such as phenolic or epoxy, is formulated to withstand high pressure and heat, making it suitable for large, durable parts with excellent mechanical strength and heat resistance. Both resins differ significantly in processing techniques, performance characteristics, and applications, with injection molding excelling in mass production and compression molding favored for heavy-duty components.

Material Properties: Comparing Injection and Compression Molding Resins

Injection molding resins are typically thermoplastics with high melt flow indices, offering excellent fluidity and rapid solidification for detailed, complex shapes. Compression molding resins often involve thermosetting polymers like polyester or epoxy, characterized by superior heat resistance and mechanical strength but lower flowability. Material selection depends on desired properties such as flexibility, durability, and production speed, with thermoplastics favoring injection molding and thermosets commonly used in compression molding.

Processing Differences Between Injection and Compression Molding Resins

Injection molding resin requires precise temperature control and high pressure to inject molten material into complex molds rapidly, enabling fine detail and high production rates. Compression molding resin, conversely, involves placing pre-measured resin into an open heated mold cavity and applying mechanical pressure to shape and cure the material, which suits thicker, reinforced composites. These processing differences impact cycle times, part complexity, and resin selection based on thermal stability and viscosity.

Strengths and Limitations of Injection Molding Resin

Injection molding resin offers high precision and rapid production rates, making it ideal for complex and detailed parts. It provides excellent mechanical strength and consistent material properties but can be limited by higher tooling costs and less suitability for very large or simple shapes. Additionally, injection molding requires precise temperature control to avoid defects such as warping or sink marks.

Advantages and Disadvantages of Compression Molding Resin

Compression molding resin offers superior mechanical strength and heat resistance compared to injection molding resin, making it ideal for producing durable, high-performance parts. However, its disadvantages include longer cycle times and limited design complexity, which can restrict production efficiency and detailed component shapes. This resin type is best suited for large, simple parts where material robustness is critical.

Cost Comparison: Injection Molding Resin vs Compression Molding Resin

Injection molding resin typically incurs higher upfront costs due to the complexity of mold design and machinery requirements, but offers lower per-unit expenses for large production runs compared to compression molding resin. Compression molding resin generally involves lower initial tooling costs but results in higher material waste and longer cycle times, which can increase overall expenses for high-volume manufacturing. Cost efficiency depends on production scale, with injection molding resin favored for mass production and compression molding resin suited for smaller batches or simpler part geometries.

Typical Applications for Each Molding Resin Type

Injection molding resin is extensively used for producing complex, high-precision components like automotive parts, consumer electronics housings, and medical devices, where intricate shapes and fine details are essential. Compression molding resin is favored for manufacturing durable, heavy-duty items such as electrical insulators, kitchenware, and automotive gaskets, benefiting from its superior heat resistance and mechanical strength. Each resin type is tailored to specific industrial requirements, optimizing performance in their designated applications.

Resin Selection Criteria: Choosing the Right Molding Process

Injection molding resin must exhibit high flowability and precise thermal stability to ensure rapid filling of intricate molds, while compression molding resin requires excellent heat resistance and low shrinkage to withstand high pressure and maintain dimensional accuracy. Selection criteria prioritize resin viscosity, thermal properties, mechanical strength, and compatibility with production volume and part complexity. Material engineers often choose thermoplastics like polypropylene or ABS for injection molding, whereas thermosetting resins such as epoxy or phenolic often suit compression molding applications.

Sustainability and Environmental Impact of Both Resins

Injection molding resin typically offers improved material efficiency and lower waste generation compared to compression molding resin, contributing to a more sustainable manufacturing process. Compression molding resins often involve higher energy consumption and the use of thermosetting polymers, which pose recycling challenges and potential environmental hazards. Selecting injection molding resin enables better recyclability and reduced carbon footprint, aligning with eco-friendly production practices.

Industry Trends: Future Outlook for Injection and Compression Molding Resins

Industry trends indicate a growing preference for injection molding resins due to their ability to support high-volume, precise manufacturing with advanced thermoplastics like polypropylene and ABS. Compression molding resins, particularly thermosetting polymers such as epoxy and phenolic, maintain strong demand in automotive and aerospace sectors where durability and heat resistance are critical. Innovations in bio-based and recyclable resins are shaping the future outlook, with injection molding leading sustainable manufacturing efforts while compression molding evolves to incorporate eco-friendly materials.

Injection Molding Resin vs Compression Molding Resin Infographic

materialdif.com

materialdif.com