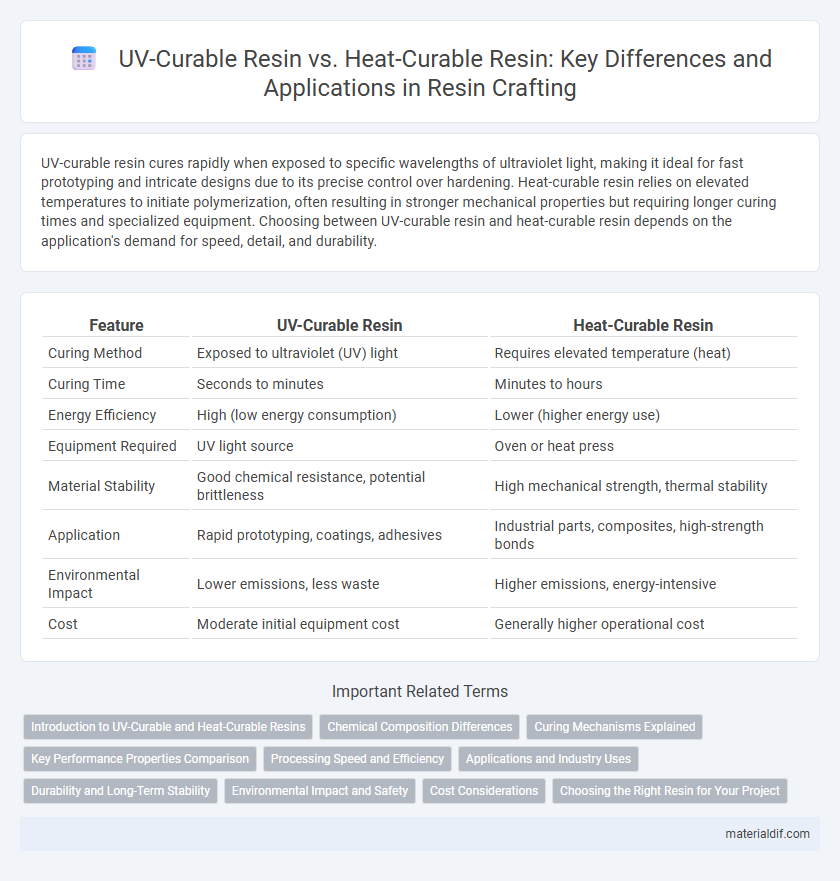

UV-curable resin cures rapidly when exposed to specific wavelengths of ultraviolet light, making it ideal for fast prototyping and intricate designs due to its precise control over hardening. Heat-curable resin relies on elevated temperatures to initiate polymerization, often resulting in stronger mechanical properties but requiring longer curing times and specialized equipment. Choosing between UV-curable resin and heat-curable resin depends on the application's demand for speed, detail, and durability.

Table of Comparison

| Feature | UV-Curable Resin | Heat-Curable Resin |

|---|---|---|

| Curing Method | Exposed to ultraviolet (UV) light | Requires elevated temperature (heat) |

| Curing Time | Seconds to minutes | Minutes to hours |

| Energy Efficiency | High (low energy consumption) | Lower (higher energy use) |

| Equipment Required | UV light source | Oven or heat press |

| Material Stability | Good chemical resistance, potential brittleness | High mechanical strength, thermal stability |

| Application | Rapid prototyping, coatings, adhesives | Industrial parts, composites, high-strength bonds |

| Environmental Impact | Lower emissions, less waste | Higher emissions, energy-intensive |

| Cost | Moderate initial equipment cost | Generally higher operational cost |

Introduction to UV-Curable and Heat-Curable Resins

UV-curable resins polymerize rapidly upon exposure to ultraviolet light, offering precise control and fast curing times essential for applications like 3D printing and coatings. Heat-curable resins, on the other hand, require elevated temperatures to initiate cross-linking reactions, providing enhanced thermal stability and mechanical strength suitable for high-performance composites and adhesives. Understanding the fundamental curing mechanisms of UV-curable and heat-curable resins enables optimized material selection based on processing speed, durability, and application-specific demands.

Chemical Composition Differences

UV-curable resins contain photoinitiators that trigger polymerization upon exposure to ultraviolet light, enabling rapid curing through free-radical or cationic mechanisms. Heat-curable resins rely on thermal initiators or hardeners such as peroxides or anhydrides to initiate chemical cross-linking when exposed to elevated temperatures. The key chemical composition difference lies in the presence of photoactive groups in UV-curable resins versus thermally reactive functional groups in heat-curable resins.

Curing Mechanisms Explained

UV-curable resin polymerizes quickly when exposed to ultraviolet light through a photoinitiated reaction, enabling rapid solidification and precise control over curing depth. Heat-curable resin requires elevated temperatures to activate thermal initiators, initiating a free-radical or cationic polymerization process that results in a gradual curing phase. The fundamental difference lies in UV light triggering instantaneous cross-linking, whereas heat curing depends on temperature-induced chemical activation for resin hardening.

Key Performance Properties Comparison

UV-curable resin offers rapid curing times under UV light, resulting in high dimensional accuracy and superior surface finishes, making it ideal for detailed applications. Heat-curable resin typically requires longer curing cycles and elevated temperatures, providing enhanced thermal stability and mechanical strength suitable for high-stress environments. Both resins exhibit excellent adhesion properties, but UV-curable resin excels in precision and speed, while heat-curable resin delivers greater durability and resistance to heat-induced deformation.

Processing Speed and Efficiency

UV-curable resin offers significantly faster processing speeds compared to heat-curable resin, curing in seconds under ultraviolet light versus minutes or hours of heat exposure. This rapid curing enhances production efficiency by reducing cycle times and energy consumption. Manufacturers benefit from increased throughput and lower operational costs when using UV-curable resin in industrial applications.

Applications and Industry Uses

UV-curable resin offers rapid curing times and high precision, making it ideal for electronics, dental, and 3D printing industries where intricate detailing and fast production are essential. Heat-curable resin provides superior thermal stability and mechanical strength, commonly utilized in automotive, aerospace, and industrial coatings that require durable, long-lasting materials. Both types serve critical roles across manufacturing sectors, selected based on specific application needs such as curing speed, environmental resistance, and mechanical performance.

Durability and Long-Term Stability

UV-curable resin offers superior long-term stability due to its rapid curing process, which creates a dense polymer network resistant to environmental degradation. Heat-curable resin provides excellent durability under high-temperature conditions but may suffer from gradual brittleness and yellowing over time. Both resins deliver strong performance, yet UV-curable variants maintain dimensional stability and mechanical strength more effectively for extended applications.

Environmental Impact and Safety

UV-curable resins significantly reduce environmental impact by eliminating solvents and lowering VOC emissions compared to heat-curable resins, which often require high energy input and release more volatile organic compounds. Safety benefits of UV-curable resins include minimal exposure to hazardous fumes and lower curing temperatures, reducing fire risks and worker exposure to heat. In contrast, heat-curable resins involve prolonged exposure to elevated temperatures, increasing energy consumption and potential harmful emissions.

Cost Considerations

UV-curable resin generally offers lower operational costs due to faster curing times and reduced energy consumption compared to heat-curable resin, which requires prolonged exposure to high temperatures and specialized heating equipment. The initial investment in UV-curing systems may be higher, but the overall efficiency and reduced processing time result in cost savings for large-scale production. Heat-curable resin systems incur higher utility expenses and longer cycle times, impacting total cost efficiency in industrial applications.

Choosing the Right Resin for Your Project

UV-curable resin offers rapid curing times and precise detailing, making it ideal for projects requiring fine resolution and quick turnaround. Heat-curable resin provides superior mechanical strength and thermal resistance, suitable for applications demanding durability and heat endurance. Selecting the right resin depends on project requirements such as curing speed, material properties, and environmental conditions to optimize performance and cost-efficiency.

UV-Curable Resin vs Heat-Curable Resin Infographic

materialdif.com

materialdif.com