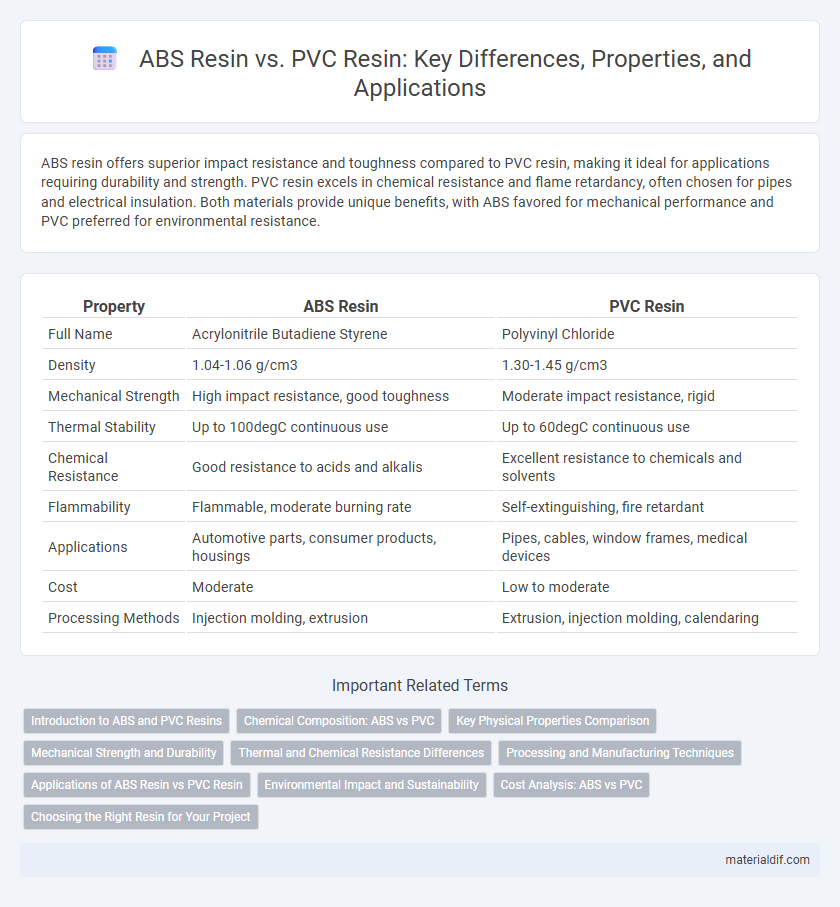

ABS resin offers superior impact resistance and toughness compared to PVC resin, making it ideal for applications requiring durability and strength. PVC resin excels in chemical resistance and flame retardancy, often chosen for pipes and electrical insulation. Both materials provide unique benefits, with ABS favored for mechanical performance and PVC preferred for environmental resistance.

Table of Comparison

| Property | ABS Resin | PVC Resin |

|---|---|---|

| Full Name | Acrylonitrile Butadiene Styrene | Polyvinyl Chloride |

| Density | 1.04-1.06 g/cm3 | 1.30-1.45 g/cm3 |

| Mechanical Strength | High impact resistance, good toughness | Moderate impact resistance, rigid |

| Thermal Stability | Up to 100degC continuous use | Up to 60degC continuous use |

| Chemical Resistance | Good resistance to acids and alkalis | Excellent resistance to chemicals and solvents |

| Flammability | Flammable, moderate burning rate | Self-extinguishing, fire retardant |

| Applications | Automotive parts, consumer products, housings | Pipes, cables, window frames, medical devices |

| Cost | Moderate | Low to moderate |

| Processing Methods | Injection molding, extrusion | Extrusion, injection molding, calendaring |

Introduction to ABS and PVC Resins

ABS resin, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its high impact resistance, toughness, and ease of processing, commonly used in automotive parts and consumer electronics. PVC resin, or Polyvinyl Chloride, is a versatile plastic characterized by its chemical resistance, durability, and flexibility, widely utilized in construction, piping, and packaging applications. Both ABS and PVC resins offer unique mechanical and physical properties that make them suitable for diverse industrial uses, with ABS excelling in strength and surface finish, while PVC provides superior chemical stability and cost-effectiveness.

Chemical Composition: ABS vs PVC

ABS resin is a terpolymer composed of acrylonitrile, butadiene, and styrene, offering a balanced combination of toughness, rigidity, and impact resistance. PVC resin, or polyvinyl chloride, consists primarily of vinyl chloride monomers and is known for its chemical resistance, durability, and versatility in rigid and flexible applications. The differences in chemical composition between ABS and PVC resins result in distinct thermal properties, mechanical strength, and resistance to environmental factors, influencing their suitability for various industrial uses.

Key Physical Properties Comparison

ABS resin exhibits higher impact resistance and better toughness compared to PVC resin, making it ideal for applications requiring durability and flexibility. PVC resin offers superior chemical resistance and flame retardancy, with greater hardness and rigidity than ABS, suitable for construction and piping uses. Both resins have distinct density ranges: ABS typically around 1.04 g/cm3, while PVC generally ranges from 1.3 to 1.45 g/cm3, influencing their weight and application suitability.

Mechanical Strength and Durability

ABS resin offers superior mechanical strength compared to PVC resin, making it ideal for applications requiring impact resistance and toughness. PVC resin excels in durability, particularly in chemical and weather resistance, which prolongs its lifespan in harsh environments. The choice between ABS and PVC resin depends largely on the balance needed between impact strength and environmental durability.

Thermal and Chemical Resistance Differences

ABS resin exhibits superior thermal resistance with a heat deflection temperature typically around 100degC, making it suitable for applications requiring moderate heat endurance, while PVC resin offers lower thermal resistance, generally withstanding temperatures up to about 60degC. Chemically, PVC resin provides excellent resistance to acids, alkalis, and many solvents, making it preferred for chemical exposure environments, whereas ABS resin is less resistant to strong chemicals but demonstrates better resistance to oils and fuels. These differences in thermal and chemical resistance properties dictate their selection in industries such as automotive, construction, and electrical components.

Processing and Manufacturing Techniques

ABS resin offers excellent processability through injection molding and extrusion, providing faster cycle times and superior impact resistance in manufactured parts. PVC resin, processed primarily via extrusion and calendering, delivers excellent chemical resistance and dimensional stability but requires precise temperature control to avoid degradation. Both resins demand specific temperature ranges for optimal melting and shaping, with ABS typically processing at 210-250degC and PVC at 160-190degC.

Applications of ABS Resin vs PVC Resin

ABS resin is widely used in automotive parts, consumer electronics housings, and toys due to its excellent impact resistance and ease of processing. PVC resin finds extensive application in construction materials like pipes, window profiles, and flooring because of its durability and chemical resistance. The choice between ABS and PVC resins depends on the required mechanical properties and environmental exposure in specific applications.

Environmental Impact and Sustainability

ABS resin generates more environmental concerns due to its petroleum-based origin and difficulty in recycling compared to PVC resin, which has established recycling streams and lower greenhouse gas emissions during production. PVC resin poses risks related to chlorine content, potentially releasing dioxins during incineration, necessitating controlled disposal methods to minimize ecological harm. Sustainable alternatives focus on bio-based ABS and improved PVC formulations to reduce carbon footprints and enhance recyclability in industrial applications.

Cost Analysis: ABS vs PVC

ABS resin generally has a higher production cost than PVC resin due to its more complex polymerization process and raw material expenses. PVC resin offers a cost-effective option, especially in large-scale applications, because of its lower material costs and ease of processing. When evaluating total expenditure, PVC resin often results in reduced manufacturing and maintenance costs compared to ABS resin, making it preferable for budget-conscious projects.

Choosing the Right Resin for Your Project

ABS resin offers superior impact resistance and heat tolerance, making it ideal for automotive parts, consumer electronics, and protective housings. PVC resin excels in chemical resistance, weatherability, and flame retardancy, frequently used in piping, electrical insulation, and construction materials. Selecting the right resin depends on project-specific requirements such as mechanical strength, environmental exposure, and regulatory compliance.

ABS resin vs PVC resin Infographic

materialdif.com

materialdif.com