Acrylic resin offers excellent clarity, UV resistance, and color stability, making it ideal for decorative and artistic pet projects, while polyurethane resin provides superior flexibility, impact resistance, and durability, better suited for functional or protective pet items. Acrylic resin cures faster and produces a harder finish, whereas polyurethane resin cures more slowly but results in a more resilient and flexible final product. Choosing between acrylic and polyurethane resin depends on whether the pet item prioritizes aesthetic appeal or mechanical robustness.

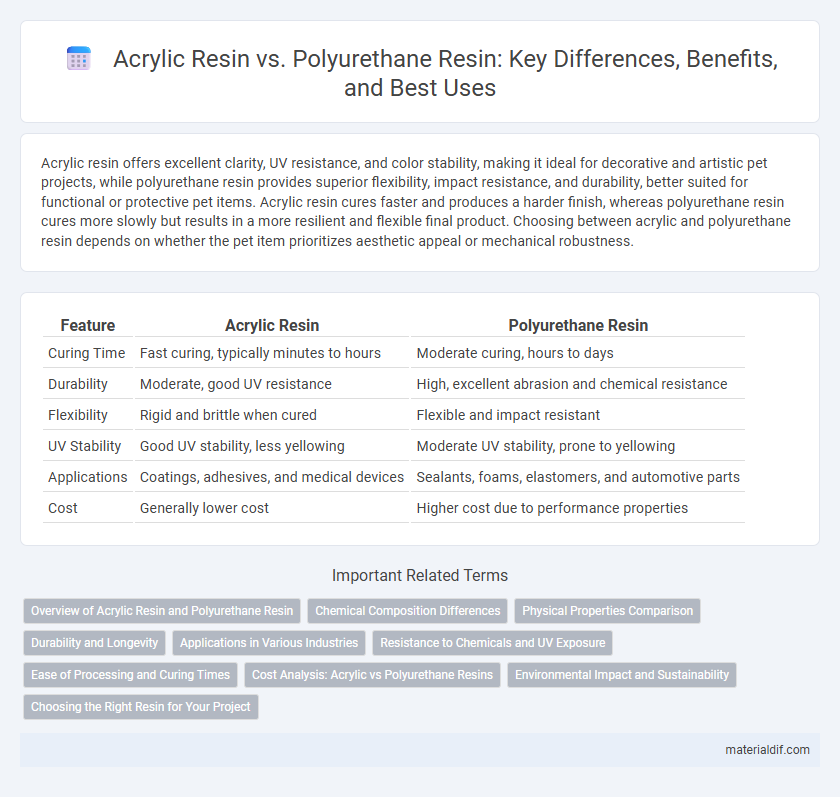

Table of Comparison

| Feature | Acrylic Resin | Polyurethane Resin |

|---|---|---|

| Curing Time | Fast curing, typically minutes to hours | Moderate curing, hours to days |

| Durability | Moderate, good UV resistance | High, excellent abrasion and chemical resistance |

| Flexibility | Rigid and brittle when cured | Flexible and impact resistant |

| UV Stability | Good UV stability, less yellowing | Moderate UV stability, prone to yellowing |

| Applications | Coatings, adhesives, and medical devices | Sealants, foams, elastomers, and automotive parts |

| Cost | Generally lower cost | Higher cost due to performance properties |

Overview of Acrylic Resin and Polyurethane Resin

Acrylic resin, known for its clarity, UV resistance, and weatherability, is widely used in applications requiring durable, transparent finishes such as coatings, adhesives, and inks. Polyurethane resin offers superior flexibility, abrasion resistance, and chemical durability, making it ideal for industrial coatings, elastomers, and sealants. Both resins provide versatile properties, with acrylic excelling in stiffness and UV stability, while polyurethane stands out for toughness and elasticity.

Chemical Composition Differences

Acrylic resin consists primarily of polymers derived from acrylic acid or methacrylic acid, featuring ester functional groups that provide clarity, UV resistance, and rigidity. Polyurethane resin is formed through the reaction of polyols with isocyanates, producing urethane linkages that result in greater flexibility, abrasion resistance, and impact strength. The chemical composition difference centers on acrylic resins being polyester-based with ester groups, while polyurethane resins contain urethane groups formed by the polyaddition process.

Physical Properties Comparison

Acrylic resin exhibits high transparency, excellent weather resistance, and good hardness, making it suitable for optical applications and outdoor coatings. Polyurethane resin offers superior flexibility, abrasion resistance, and impact strength, ideal for flexible foams and durable coatings. While acrylic resins tend to be more rigid and UV stable, polyurethane resins provide better elasticity and wear resistance under mechanical stress.

Durability and Longevity

Acrylic resin exhibits superior UV resistance, maintaining color and structural integrity over time, making it highly durable for outdoor applications. Polyurethane resin offers exceptional flexibility and abrasion resistance, extending its longevity under mechanical stress and impact. Both resins provide excellent durability, but acrylic resin is preferred for prolonged exposure to sunlight, while polyurethane excels in wear-prone environments.

Applications in Various Industries

Acrylic resin is widely used in automotive coatings, adhesives, and construction materials due to its excellent UV resistance and clarity. Polyurethane resin dominates in flexible foam production, footwear, and industrial coatings because of its superior elasticity and abrasion resistance. Both resins are integral in electronics packaging and marine applications, where durability and environmental resistance are critical factors.

Resistance to Chemicals and UV Exposure

Acrylic resin offers superior UV resistance, maintaining clarity and structural integrity even under prolonged sunlight exposure, making it ideal for outdoor applications. Polyurethane resin excels in chemical resistance, particularly against oils, solvents, and abrasion, ensuring durability in harsh industrial environments. Both resins provide robust performance, but the choice depends on prioritizing UV stability with acrylics or chemical resilience with polyurethanes.

Ease of Processing and Curing Times

Acrylic resin offers faster curing times compared to polyurethane resin, making it ideal for projects requiring quick turnaround and minimal downtime. Polyurethane resin, while typically slower to cure, provides greater ease of processing due to its superior flexibility and resistance to shrinkage during molding. Both resins are suitable for different applications, with acrylic favored for rapid prototyping and polyurethane preferred for detailed, durable finishes.

Cost Analysis: Acrylic vs Polyurethane Resins

Acrylic resins generally offer a lower initial cost compared to polyurethane resins, making them more affordable for large-scale applications or budget-sensitive projects. Polyurethane resins, while more expensive upfront, provide superior durability and resistance to chemicals and abrasion, which can reduce long-term maintenance and replacement expenses. The overall cost analysis depends on the specific application requirements, with acrylic resins favored for cost-efficiency and polyurethane resins preferred for performance and longevity.

Environmental Impact and Sustainability

Acrylic resin typically demonstrates lower environmental impact due to its water-based formulation and higher recyclability compared to polyurethane resin, which often relies on petrochemical components and emits more volatile organic compounds (VOCs) during curing. Polyurethane resins generally possess superior durability and chemical resistance but pose greater challenges for biodegradability and end-of-life disposal. Choosing acrylic resin aligns better with sustainability goals through reduced greenhouse gas emissions and enhanced potential for circular material usage in manufacturing.

Choosing the Right Resin for Your Project

Acrylic resin offers superior UV resistance and clarity, making it ideal for outdoor applications and art projects requiring vibrant colors. Polyurethane resin provides excellent flexibility and durability, suitable for casting, coatings, and industrial parts exposed to wear and impact. Selecting the right resin depends on project needs such as exposure to elements, mechanical stress, and desired finish quality.

Acrylic Resin vs Polyurethane Resin Infographic

materialdif.com

materialdif.com