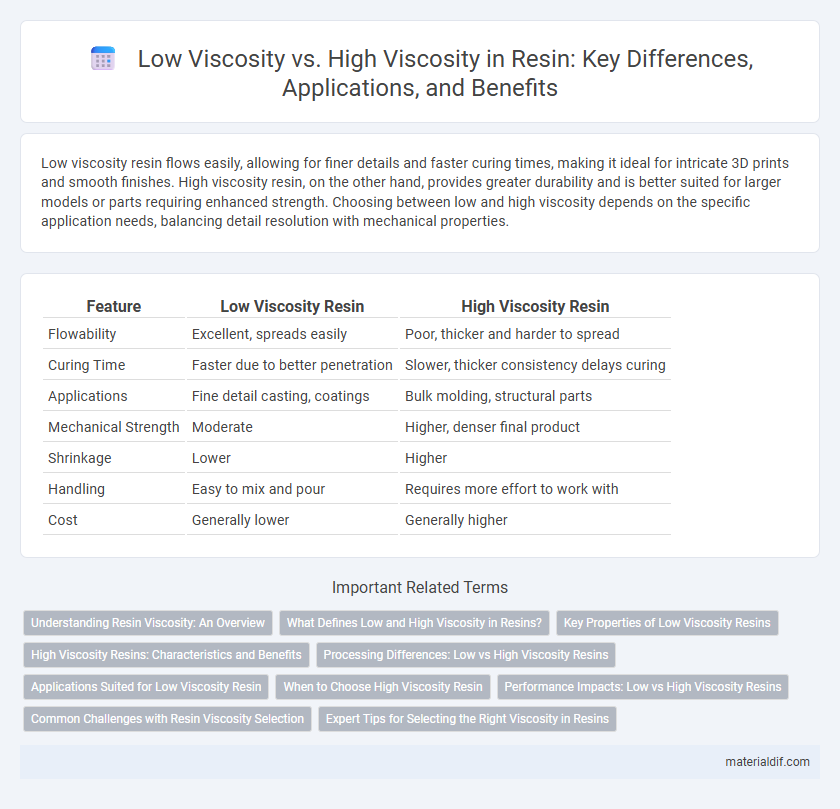

Low viscosity resin flows easily, allowing for finer details and faster curing times, making it ideal for intricate 3D prints and smooth finishes. High viscosity resin, on the other hand, provides greater durability and is better suited for larger models or parts requiring enhanced strength. Choosing between low and high viscosity depends on the specific application needs, balancing detail resolution with mechanical properties.

Table of Comparison

| Feature | Low Viscosity Resin | High Viscosity Resin |

|---|---|---|

| Flowability | Excellent, spreads easily | Poor, thicker and harder to spread |

| Curing Time | Faster due to better penetration | Slower, thicker consistency delays curing |

| Applications | Fine detail casting, coatings | Bulk molding, structural parts |

| Mechanical Strength | Moderate | Higher, denser final product |

| Shrinkage | Lower | Higher |

| Handling | Easy to mix and pour | Requires more effort to work with |

| Cost | Generally lower | Generally higher |

Understanding Resin Viscosity: An Overview

Resin viscosity significantly impacts application methods and curing times, with low viscosity resins offering easier flow and better penetration for intricate molds, while high viscosity resins provide thicker consistency ideal for layering and sculpting. Low viscosity types, typically below 500 centipoise, enable faster wetting of surfaces, reducing air bubble entrapment, whereas high viscosity resins, often above 1,500 centipoise, ensure stability in vertical applications and support heavier additives. Understanding these properties is crucial for selecting the right resin type based on project requirements such as casting details, cure speed, and environmental conditions.

What Defines Low and High Viscosity in Resins?

Low viscosity in resins is defined by a fluidity that allows easy flow and penetration, typically measured below 1000 centipoise, making it ideal for applications requiring smooth coating and impregnation. High viscosity resins, generally exceeding 5000 centipoise, exhibit thicker consistency and slower flow, suited for molding and structural uses where shape retention and build-up thickness are critical. The viscosity depends on resin chemistry, temperature, and molecular weight, influencing curing behavior and final mechanical properties.

Key Properties of Low Viscosity Resins

Low viscosity resins exhibit superior flow characteristics, enabling enhanced penetration into fine substrates and intricate molds, which is essential for applications requiring detailed replication and uniform coating. These resins offer faster curing times and improved wetting ability, leading to stronger adhesion and reduced chances of void formation in composites. Their low resistance to flow makes them ideal for infusion processes, ensuring optimal fiber impregnation and overall composite performance.

High Viscosity Resins: Characteristics and Benefits

High viscosity resins exhibit thicker consistency, enhancing their adhesive strength and durability in coatings, composites, and adhesives. Their slower flow rate provides superior control during application, reducing drips and sagging while ensuring better fill of joints and cavities. These resins are ideal for structural applications requiring robust mechanical properties and high chemical resistance.

Processing Differences: Low vs High Viscosity Resins

Low viscosity resins flow more easily, enabling faster impregnation of fibers and shorter curing times in composite manufacturing. High viscosity resins require higher temperatures or mechanical mixing to reduce thickness, which can extend processing time and increase energy consumption. Understanding these differences is crucial for selecting the appropriate resin type based on application requirements and production efficiency.

Applications Suited for Low Viscosity Resin

Low viscosity resin enables superior flow and penetration, making it ideal for intricate mold casting, composite manufacturing, and coatings requiring thin, even layers. Its ability to wet substrates thoroughly ensures optimal adhesion in applications like aerospace components, dental materials, and electronics encapsulation. This resin type supports faster curing and more consistent results in vacuum infusion and resin transfer molding processes.

When to Choose High Viscosity Resin

High viscosity resin is ideal for applications requiring enhanced strength and durability, such as heavy-duty coatings, structural adhesives, and thick composite materials. Its thicker consistency ensures better gap-filling capabilities and reduces the risk of sagging or dripping in vertical or overhead applications. Select high viscosity resin when precise molding detail and superior mechanical properties are critical for the final product's performance.

Performance Impacts: Low vs High Viscosity Resins

Low viscosity resins offer superior flow and penetration capabilities, enabling detailed mold filling and reduced air entrapment, leading to enhanced surface finish and mechanical strength. High viscosity resins provide increased resistance to sagging and better dimensional stability, making them ideal for vertical applications and thick laminates where structural integrity is critical. Selecting the appropriate resin viscosity directly impacts cure time, adhesion quality, and overall part performance in composites and coatings.

Common Challenges with Resin Viscosity Selection

Low viscosity resin often causes issues with insufficient film thickness and fisheye defects, while high viscosity resin can lead to poor flow and uneven coating application. Selecting the appropriate resin viscosity is critical to balance wetting, curing speed, and surface finish quality in coating or casting processes. Improper viscosity settings can result in adhesion problems, bubbles, and inconsistent mechanical properties in the final product.

Expert Tips for Selecting the Right Viscosity in Resins

Low viscosity resins offer superior flow and penetration, ideal for detailed molds and complex casting, while high viscosity resins provide enhanced control and reduce sagging in vertical applications. Experts recommend selecting resin viscosity based on project scale, mold intricacy, and curing time constraints to ensure optimal results. Testing small batches can help determine the best balance between workability and structural integrity for specific resin formulations.

Low Viscosity vs High Viscosity Infographic

materialdif.com

materialdif.com