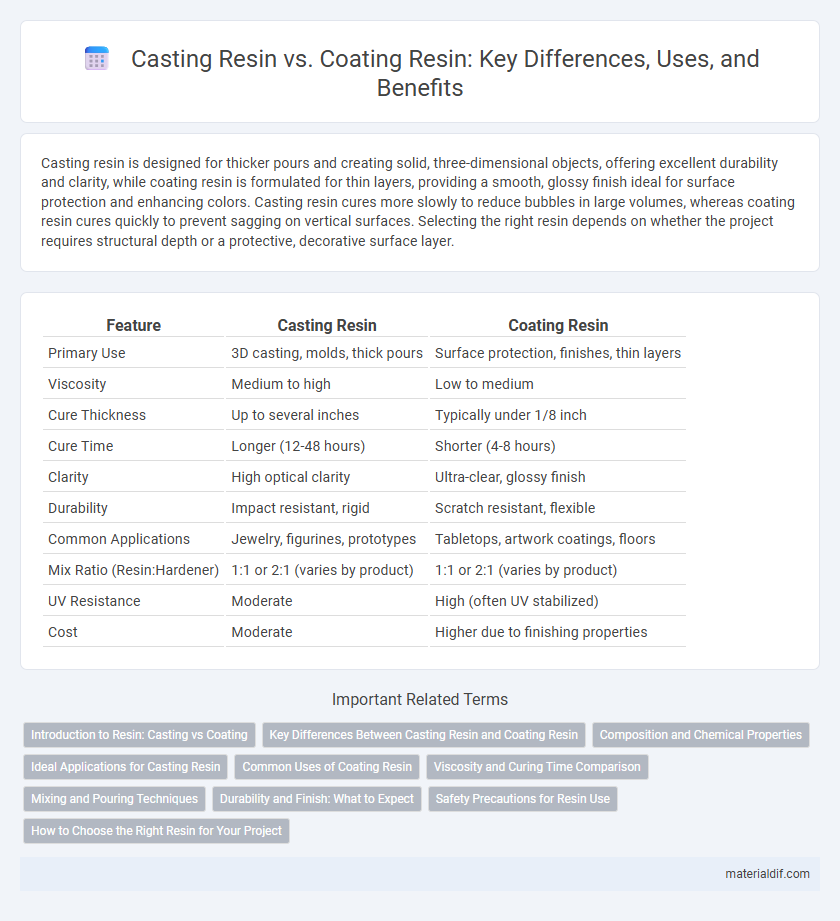

Casting resin is designed for thicker pours and creating solid, three-dimensional objects, offering excellent durability and clarity, while coating resin is formulated for thin layers, providing a smooth, glossy finish ideal for surface protection and enhancing colors. Casting resin cures more slowly to reduce bubbles in large volumes, whereas coating resin cures quickly to prevent sagging on vertical surfaces. Selecting the right resin depends on whether the project requires structural depth or a protective, decorative surface layer.

Table of Comparison

| Feature | Casting Resin | Coating Resin |

|---|---|---|

| Primary Use | 3D casting, molds, thick pours | Surface protection, finishes, thin layers |

| Viscosity | Medium to high | Low to medium |

| Cure Thickness | Up to several inches | Typically under 1/8 inch |

| Cure Time | Longer (12-48 hours) | Shorter (4-8 hours) |

| Clarity | High optical clarity | Ultra-clear, glossy finish |

| Durability | Impact resistant, rigid | Scratch resistant, flexible |

| Common Applications | Jewelry, figurines, prototypes | Tabletops, artwork coatings, floors |

| Mix Ratio (Resin:Hardener) | 1:1 or 2:1 (varies by product) | 1:1 or 2:1 (varies by product) |

| UV Resistance | Moderate | High (often UV stabilized) |

| Cost | Moderate | Higher due to finishing properties |

Introduction to Resin: Casting vs Coating

Casting resin is designed for creating thick, solid objects through pouring into molds, offering high durability and clarity ideal for jewelry and art pieces. Coating resin, on the other hand, provides a thin, protective layer that enhances surfaces with a glossy, scratch-resistant finish, commonly used on tabletops and artwork. Both types utilize epoxy or polyurethane bases but differ in viscosity, curing time, and application techniques to suit their specific purposes.

Key Differences Between Casting Resin and Coating Resin

Casting resin is designed for creating thick, solid objects and can be poured in layers up to several centimeters without heat buildup or warping. Coating resin is formulated as a thin, protective finish that cures to a hard, glossy surface, ideal for sealing and enhancing wood, artwork, or countertops. Key differences include viscosity, curing time, and durability, with casting resin having higher viscosity and slower curing for depth, while coating resin offers low viscosity and rapid curing for smooth surface finishes.

Composition and Chemical Properties

Casting resin typically consists of polyester, epoxy, or polyurethane formulations designed for high viscosity and self-leveling properties, enabling it to fill molds and create solid, durable objects. Coating resin primarily uses epoxy or polyurethane bases with lower viscosity and enhanced UV and abrasion resistance, formulated to form thin, protective films over surfaces. Chemical properties differ as casting resins cure through exothermic polymerization to form rigid structures, whereas coating resins emphasize flexibility and adhesion for surface protection and durability.

Ideal Applications for Casting Resin

Casting resin is ideal for creating thick, solid objects such as jewelry, sculptures, and molds due to its ability to cure in deep layers without excessive heat buildup. It offers high clarity and excellent resistance to impact and chemicals, making it suitable for artistic and industrial applications requiring durable and detailed finishes. Unlike coating resin, casting resin is not formulated for thin, protective surface layers but excels in bulk resin projects requiring dimensional stability and structural integrity.

Common Uses of Coating Resin

Coating resin is primarily used for surface protection and enhancement, providing a clear, glossy finish that resists scratches, UV rays, and moisture damage. It is commonly applied on wood, metal, and artwork to preserve appearance and extend durability. Unlike casting resin, which fills molds and creates solid objects, coating resin is formulated for thin, even layers to seal and protect surfaces.

Viscosity and Curing Time Comparison

Casting resin typically features a lower viscosity compared to coating resin, allowing it to flow smoothly into molds and capture fine details without trapping air bubbles. Its curing time is generally longer, often ranging from 24 to 72 hours, which facilitates deep pours and prevents overheating. In contrast, coating resin has a higher viscosity to create a thick, protective layer quickly and cures faster, usually within 12 to 24 hours, making it ideal for surface finishes and enhancing durability.

Mixing and Pouring Techniques

Casting resin requires precise measuring and thorough mixing to ensure complete chemical reaction and avoid sticky or uneven results, often mixed in a 2:1 or 1:1 resin-to-hardener ratio. Pouring techniques for casting resin involve slow, steady pours to minimize air bubbles and create thick, solid forms ideal for molds. Coating resin demands a thinner, more fluid consistency with careful application in thin layers to achieve smooth, glossy finishes without trapping dust or imperfections.

Durability and Finish: What to Expect

Casting resin offers superior durability due to its thicker composition, making it ideal for creating solid, long-lasting objects with high resistance to impact and wear. Coating resin provides a smooth, glossy finish that enhances surface aesthetics but is thinner and less durable than casting resin, mainly designed for protection and visual enhancement. Expect casting resin to deliver robust, structural integrity while coating resin excels in providing a flawless, protective layer with excellent clarity.

Safety Precautions for Resin Use

Casting resin requires strict adherence to safety precautions such as working in a well-ventilated area to avoid inhaling harmful fumes and wearing nitrile gloves to prevent skin contact. Coating resin also demands protective measures including eye protection and respirators to guard against volatile organic compounds released during application. Both resin types should be stored away from heat sources and children to minimize fire risks and accidental ingestion.

How to Choose the Right Resin for Your Project

Casting resin offers thick, durable layers ideal for creating solid objects, while coating resin provides thin, clear finishes perfect for protective or decorative surfaces. Consider project requirements such as thickness, transparency, curing time, and hardness to determine the optimal resin type. Evaluating factors like viscosity, UV resistance, and flexibility ensures selecting the resin that best suits sculpting, embedding, or glossy finishing needs.

Casting Resin vs Coating Resin Infographic

materialdif.com

materialdif.com