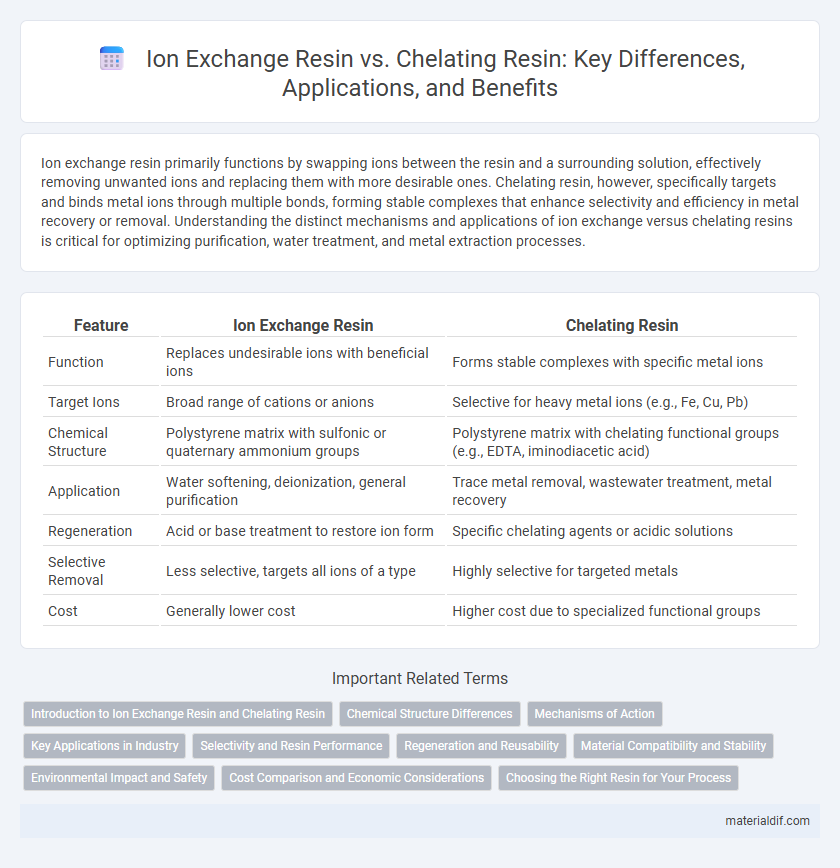

Ion exchange resin primarily functions by swapping ions between the resin and a surrounding solution, effectively removing unwanted ions and replacing them with more desirable ones. Chelating resin, however, specifically targets and binds metal ions through multiple bonds, forming stable complexes that enhance selectivity and efficiency in metal recovery or removal. Understanding the distinct mechanisms and applications of ion exchange versus chelating resins is critical for optimizing purification, water treatment, and metal extraction processes.

Table of Comparison

| Feature | Ion Exchange Resin | Chelating Resin |

|---|---|---|

| Function | Replaces undesirable ions with beneficial ions | Forms stable complexes with specific metal ions |

| Target Ions | Broad range of cations or anions | Selective for heavy metal ions (e.g., Fe, Cu, Pb) |

| Chemical Structure | Polystyrene matrix with sulfonic or quaternary ammonium groups | Polystyrene matrix with chelating functional groups (e.g., EDTA, iminodiacetic acid) |

| Application | Water softening, deionization, general purification | Trace metal removal, wastewater treatment, metal recovery |

| Regeneration | Acid or base treatment to restore ion form | Specific chelating agents or acidic solutions |

| Selective Removal | Less selective, targets all ions of a type | Highly selective for targeted metals |

| Cost | Generally lower cost | Higher cost due to specialized functional groups |

Introduction to Ion Exchange Resin and Chelating Resin

Ion exchange resin and chelating resin are specialized polymer materials designed for selective removal of ions from solutions. Ion exchange resins function by exchanging specific ions within the resin matrix with those in the surrounding solution, commonly used for water softening and purification. Chelating resins contain functional groups that form strong, stable complexes with metal ions, making them highly effective for extracting heavy metals and trace elements from industrial and environmental samples.

Chemical Structure Differences

Ion exchange resins feature sulfonic or carboxylic acid functional groups attached to a polymer matrix, enabling reversible exchange of ions based on charge attraction. Chelating resins incorporate multidentate ligands like aminophosphonate or iminodiacetic acid groups, allowing selective binding of metal ions through multiple coordination sites. The primary chemical structure difference lies in ion exchange resins relying on single-site ionic interactions, while chelating resins form stable, ring-like complexes via multiple coordination bonds.

Mechanisms of Action

Ion exchange resins function by exchanging ions between the resin and the solution, selectively removing unwanted ions through electrostatic attraction. Chelating resins possess specific functional groups that form stable coordination complexes with metal ions, enabling targeted metal ion binding through chelation. The primary difference lies in ion exchange resins relying on ion substitution while chelating resins form strong covalent-like bonds with metal ions for enhanced selectivity and capacity.

Key Applications in Industry

Ion exchange resins are widely utilized in water softening, demineralization, and purification processes within industries such as power generation, pharmaceuticals, and food processing. Chelating resins are specialized for selective removal of heavy metals and recovery of precious metals in mining, environmental remediation, and electroplating industries. Both resins play critical roles in optimizing industrial water treatment and metal extraction applications.

Selectivity and Resin Performance

Ion exchange resin exhibits high selectivity for specific ions based on charge and size, making it ideal for water softening and deionization. Chelating resin provides superior selectivity for metal ions through stable complex formation, enhancing metal recovery and removal efficiency. Resin performance in industrial applications depends on resin capacity, regeneration efficiency, and resistance to fouling or degradation.

Regeneration and Reusability

Ion exchange resins are regenerated by reversing ion adsorption through chemical treatment with acids or bases, allowing multiple reuse cycles while maintaining high ion removal efficiency. Chelating resins require more specific regenerants like EDTA or acids designed to break metal-ligand bonds, which can be less straightforward and may reduce resin lifespan due to ligand degradation. The regeneration process of ion exchange resins is generally more efficient and cost-effective, enhancing their reusability compared to chelating resins in industrial water treatment applications.

Material Compatibility and Stability

Ion exchange resins, typically composed of sulfonated polystyrene or polyacrylic acid, offer high chemical stability and broad compatibility with acidic or neutral solutions, making them suitable for water softening and purification. Chelating resins, often based on polyacrylic matrices functionalized with aminophosphonic or iminodiacetic acid groups, exhibit selective binding for heavy metals but can be less stable under extreme pH conditions due to ligand sensitivity. Material compatibility in ion exchange resins favors durable performance in harsh environments, whereas chelating resins prioritize metal specificity with moderate chemical stability limitations.

Environmental Impact and Safety

Ion exchange resins primarily facilitate ion replacement, offering efficient water purification with minimal chemical waste compared to traditional methods, thus lowering environmental footprint. Chelating resins, designed to selectively bind metal ions, enhance heavy metal removal from industrial wastewater but may generate complex waste requiring careful disposal to mitigate ecological risks. Both resins pose low toxicity risks during handling, yet proper containment and regeneration procedures are crucial to prevent accidental release of hazardous substances into the environment.

Cost Comparison and Economic Considerations

Ion exchange resins generally have lower upfront costs compared to chelating resins, making them more economical for large-scale water treatment applications. Chelating resins, while more expensive, offer superior selectivity for heavy metals, which can reduce operational expenses by minimizing regeneration cycles and chemical usage. Evaluating total lifecycle costs, including purchase price, regeneration frequency, and resin longevity, is crucial for determining the most cost-effective choice for specific industrial processes.

Choosing the Right Resin for Your Process

Ion exchange resins excel in removing dissolved ions through reversible exchange processes, making them ideal for water softening and deionization in industrial applications. Chelating resins selectively bind specific metal ions using functional groups, providing superior performance in heavy metal recovery and purification tasks. Selecting the right resin depends on process goals, with ion exchange favored for broad ion removal and chelating resins chosen for targeted metal ion separation.

Ion Exchange Resin vs Chelating Resin Infographic

materialdif.com

materialdif.com