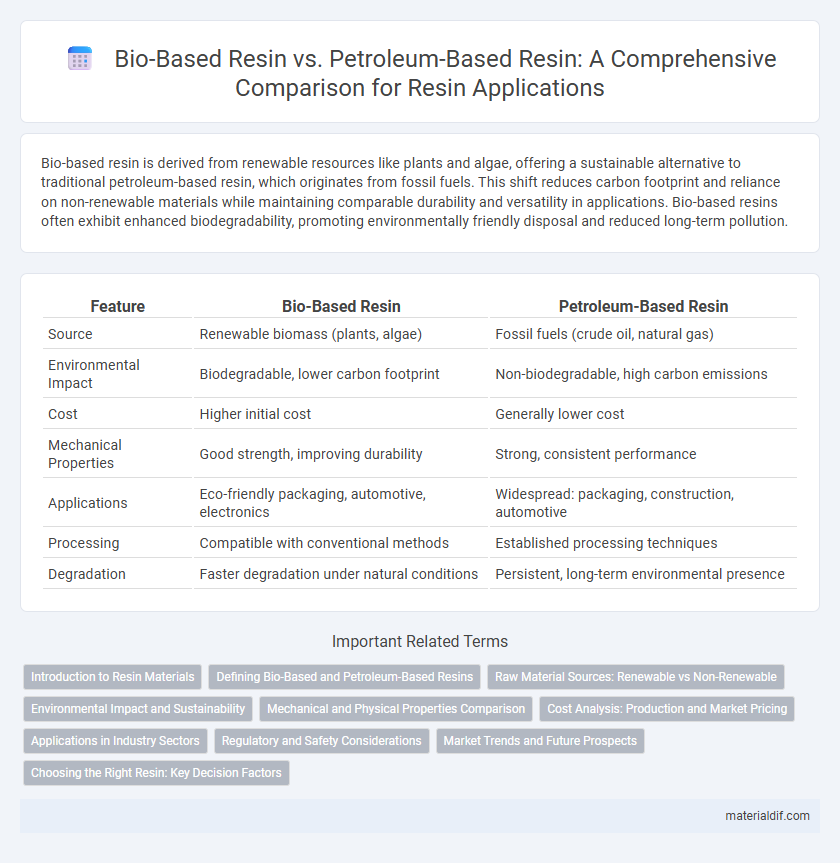

Bio-based resin is derived from renewable resources like plants and algae, offering a sustainable alternative to traditional petroleum-based resin, which originates from fossil fuels. This shift reduces carbon footprint and reliance on non-renewable materials while maintaining comparable durability and versatility in applications. Bio-based resins often exhibit enhanced biodegradability, promoting environmentally friendly disposal and reduced long-term pollution.

Table of Comparison

| Feature | Bio-Based Resin | Petroleum-Based Resin |

|---|---|---|

| Source | Renewable biomass (plants, algae) | Fossil fuels (crude oil, natural gas) |

| Environmental Impact | Biodegradable, lower carbon footprint | Non-biodegradable, high carbon emissions |

| Cost | Higher initial cost | Generally lower cost |

| Mechanical Properties | Good strength, improving durability | Strong, consistent performance |

| Applications | Eco-friendly packaging, automotive, electronics | Widespread: packaging, construction, automotive |

| Processing | Compatible with conventional methods | Established processing techniques |

| Degradation | Faster degradation under natural conditions | Persistent, long-term environmental presence |

Introduction to Resin Materials

Bio-based resin is derived from renewable biological sources such as plants, offering eco-friendly alternatives to traditional petroleum-based resins, which are synthesized from fossil fuels. These materials differ in chemical composition and environmental impact, with bio-based resins reducing carbon footprint and enhancing sustainability in manufacturing. Both resin types are integral to industries like packaging, automotive, and construction, where performance and ecological concerns influence material selection.

Defining Bio-Based and Petroleum-Based Resins

Bio-based resins are derived from renewable organic materials such as plant oils, starches, and cellulose, offering a sustainable alternative with reduced carbon footprints compared to traditional plastics. Petroleum-based resins originate from fossil fuels like crude oil and natural gas, providing high performance and durability but contributing to environmental pollution and resource depletion. Understanding the chemical composition and source of these resins is crucial for applications in eco-friendly manufacturing and product design.

Raw Material Sources: Renewable vs Non-Renewable

Bio-based resin is derived from renewable raw materials such as plant oils, starches, and cellulose, offering a sustainable alternative to petroleum-based resin, which relies on finite, non-renewable fossil fuels like crude oil and natural gas. The renewable sources for bio-based resins reduce carbon footprint and dependence on depleting resources, enhancing environmental benefits through biodegradability and lower greenhouse gas emissions. Petroleum-based resins, while historically dominant due to cost-efficiency and established supply chains, face challenges related to resource scarcity and ecological impact.

Environmental Impact and Sustainability

Bio-based resins derive from renewable resources such as plant oils and natural fibers, significantly reducing carbon emissions and reliance on fossil fuels compared to petroleum-based resins, which contribute to greenhouse gas emissions and environmental degradation through extraction and processing. The biodegradability of bio-based resins enhances waste management and soil health, in contrast to petroleum-based resins that persist in the environment, causing long-term pollution and microplastic accumulation. Sustainable production of bio-based resins supports circular economies and lowers ecological footprints by minimizing energy consumption and fostering carbon sequestration during biomass growth.

Mechanical and Physical Properties Comparison

Bio-based resins exhibit superior mechanical properties such as higher tensile strength and better impact resistance compared to petroleum-based resins, making them suitable for durable applications. Physically, bio-based resins often show enhanced thermal stability and lower density, contributing to lightweight and heat-resistant products. Petroleum-based resins generally provide consistent performance with well-established processing techniques but tend to have higher environmental impact due to their fossil fuel origin.

Cost Analysis: Production and Market Pricing

Bio-based resin production typically incurs higher costs due to raw material sourcing from renewable biomass and more complex processing methods compared to petroleum-based resin, which benefits from established extraction and refining infrastructure. Market pricing of bio-based resins reflects these elevated production expenses, resulting in a premium price point relative to petroleum-based alternatives. However, long-term trends indicate potential cost reductions in bio-based resin manufacturing driven by technological advancements and growing demand for sustainable materials.

Applications in Industry Sectors

Bio-based resins are increasingly utilized in packaging, automotive components, and construction materials due to their sustainability and biodegradability, offering an eco-friendly alternative to traditional materials. Petroleum-based resins dominate in electronics, aerospace, and high-performance industrial coatings, valued for their durability, thermal stability, and mechanical strength. The choice between bio-based and petroleum-based resins hinges on specific industrial application requirements, balancing environmental impact with performance characteristics.

Regulatory and Safety Considerations

Bio-based resins are gaining regulatory favor due to their lower environmental impact and reduced emissions of volatile organic compounds (VOCs) compared to petroleum-based resins, which often face stricter regulations related to hazardous air pollutants and carcinogenic substances. Safety considerations increasingly prioritize bio-based resins for their biodegradability and lower toxicity, aligning with global initiatives such as REACH and TSCA that impose rigorous safety standards on chemical substances. Compliance with these regulations ensures that bio-based resins offer a safer alternative in manufacturing processes, reducing health risks for workers and minimizing ecological damage.

Market Trends and Future Prospects

Market trends show a rising demand for bio-based resins driven by growing environmental concerns and regulatory support for sustainable materials. Bio-based resins, derived from renewable resources such as plant oils and starch, offer reduced carbon footprints compared to petroleum-based resins, which dominate the current market due to their established supply chains and cost advantages. Future prospects indicate increased investment in bio-based resin technologies and expanding applications in automotive, packaging, and construction sectors as industries shift towards greener alternatives.

Choosing the Right Resin: Key Decision Factors

Choosing the right resin involves evaluating environmental impact, performance characteristics, and cost efficiency. Bio-based resin offers renewable sourcing and reduced carbon footprint, making it ideal for sustainable applications, while petroleum-based resin provides superior durability and thermal stability for demanding industrial uses. Decision factors include application requirements, regulatory compliance, and long-term environmental goals.

Bio-Based Resin vs Petroleum-Based Resin Infographic

materialdif.com

materialdif.com