DCPD resin offers superior chemical resistance and flexibility compared to Bisphenol-A resin, making it ideal for automotive parts and protective coatings. Bisphenol-A resin provides excellent thermal stability and mechanical strength, which is favored in electronic encapsulation and adhesives. Choosing between DCPD and Bisphenol-A resin depends on specific application requirements such as environmental exposure and performance criteria.

Table of Comparison

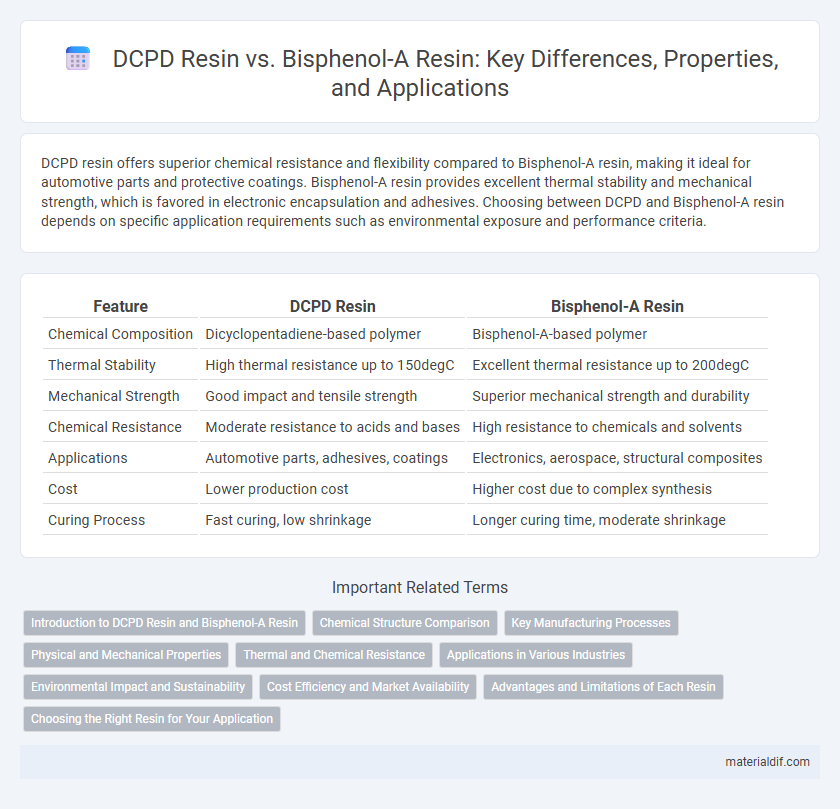

| Feature | DCPD Resin | Bisphenol-A Resin |

|---|---|---|

| Chemical Composition | Dicyclopentadiene-based polymer | Bisphenol-A-based polymer |

| Thermal Stability | High thermal resistance up to 150degC | Excellent thermal resistance up to 200degC |

| Mechanical Strength | Good impact and tensile strength | Superior mechanical strength and durability |

| Chemical Resistance | Moderate resistance to acids and bases | High resistance to chemicals and solvents |

| Applications | Automotive parts, adhesives, coatings | Electronics, aerospace, structural composites |

| Cost | Lower production cost | Higher cost due to complex synthesis |

| Curing Process | Fast curing, low shrinkage | Longer curing time, moderate shrinkage |

Introduction to DCPD Resin and Bisphenol-A Resin

Dicyclopentadiene (DCPD) resin is a thermosetting polymer known for its excellent chemical resistance, high mechanical strength, and thermal stability, making it ideal for automotive and industrial applications. Bisphenol-A (BPA) resin, commonly used in epoxy and polycarbonate production, offers superior transparency, toughness, and resistance to heat and impact. Both resins serve distinct purposes based on their molecular structures, with DCPD providing enhanced durability in harsh environments and BPA delivering versatility in consumer and electronic products.

Chemical Structure Comparison

Dicyclopentadiene (DCPD) resin features a unique norbornene ring structure derived from cyclopentadiene, resulting in high thermal stability and chemical resistance. In contrast, Bisphenol-A (BPA) resin contains two phenol groups connected by a propane bridge, providing rigidity and excellent mechanical properties due to its aromatic rings. The distinct chemical backbones influence their performance, with DCPD offering enhanced durability in harsh environments while BPA resins excel in applications requiring structural strength and heat resistance.

Key Manufacturing Processes

DCPD resin is produced through the polymerization of dicyclopentadiene using metathesis or cationic polymerization techniques, which provide rigidity and heat resistance for industrial applications. Bisphenol-A resin, commonly synthesized via condensation polymerization of bisphenol-A with epichlorohydrin, results in epoxy resins valued for their excellent adhesion and chemical resistance. The manufacturing of DCPD resin emphasizes control over polymer structure for mechanical strength, while Bisphenol-A resin production focuses on achieving high molecular weight and cross-link density for enhanced durability.

Physical and Mechanical Properties

DCPD resin exhibits superior impact resistance and flexibility compared to Bisphenol-A resin, making it ideal for applications requiring toughness and durability. Bisphenol-A resin offers higher thermal stability and tensile strength, which suits it for structural components exposed to high temperatures. Both resins demonstrate excellent chemical resistance, but DCPD resin tends to have better dimensional stability under mechanical stress.

Thermal and Chemical Resistance

Dicyclopentadiene (DCPD) resin exhibits superior thermal stability, maintaining integrity at temperatures up to 200degC, whereas Bisphenol-A (BPA) resin typically withstands temperatures around 150degC. Chemically, DCPD resins demonstrate enhanced resistance to acids and alkalis, making them more suitable for harsh industrial environments compared to BPA resins, which are more prone to hydrolysis and chemical degradation. The molecular structure of DCPD, characterized by a strained bicyclic ring, contributes to its robust thermal and chemical resistance properties compared to the phenolic structure of BPA resin.

Applications in Various Industries

DCPD resin excels in automotive manufacturing and electrical insulation due to its superior impact resistance and thermal stability, making it ideal for producing durable bumpers, housings, and circuit boards. Bisphenol-A resin is widely used in the production of polycarbonate plastics and epoxy resins, finding applications in construction, electronics, and food packaging for its excellent chemical resistance and clarity. Both resins support high-performance industrial needs but are differentiated by their specific chemical properties that cater to distinct manufacturing requirements.

Environmental Impact and Sustainability

DCPD resin exhibits lower environmental toxicity and better biodegradability compared to Bisphenol-A (BPA) resin, which is associated with endocrine disruption and persistence in ecosystems. The production of DCPD resin generates fewer hazardous byproducts and utilizes renewable feedstocks more efficiently, enhancing its sustainability profile. In contrast, BPA resin's reliance on petrochemical sources and challenges in recycling contribute to greater environmental burdens and limited circularity.

Cost Efficiency and Market Availability

DCPD resin offers superior cost efficiency compared to Bisphenol-A resin due to its lower raw material expenses and faster curing times, making it ideal for large-scale industrial applications. Market availability of DCPD resin is expanding rapidly in sectors such as coatings, adhesives, and composites, driven by growing demand for durable, lightweight materials. In contrast, Bisphenol-A resin faces stricter regulatory constraints and higher production costs, which limit its widespread market penetration despite its established use in electronics and plastics.

Advantages and Limitations of Each Resin

DCPD resin offers superior chemical resistance and excellent electrical insulation properties, making it ideal for automotive and electrical applications, but it has limited UV stability and lower mechanical strength compared to Bisphenol-A resin. Bisphenol-A resin provides high thermal stability, strong mechanical performance, and good adhesion, widely used in coatings and adhesives; however, it is more expensive and less resistant to certain chemicals than DCPD resin. Selecting between DCPD and Bisphenol-A resins depends on application-specific requirements such as chemical exposure, mechanical load, and cost constraints.

Choosing the Right Resin for Your Application

DCPD resin offers superior impact resistance and chemical durability, making it ideal for automotive parts and electrical components exposed to harsh environments. Bisphenol-A resin excels in high thermal stability and mechanical strength, suited for applications requiring heat resistance and dimensional stability, such as electronic housings and structural adhesives. Selecting the right resin depends on balancing factors like thermal performance, chemical exposure, and mechanical demands specific to your application.

DCPD Resin vs Bisphenol-A Resin Infographic

materialdif.com

materialdif.com