Marine resin is specifically formulated to withstand harsh saltwater environments, offering superior UV resistance, flexibility, and corrosion protection compared to industrial resin. Industrial resin, while versatile and cost-effective for general applications, lacks the specialized additives that ensure long-term durability against marine exposure. Choosing marine resin is essential for projects requiring enhanced durability and performance in aquatic settings.

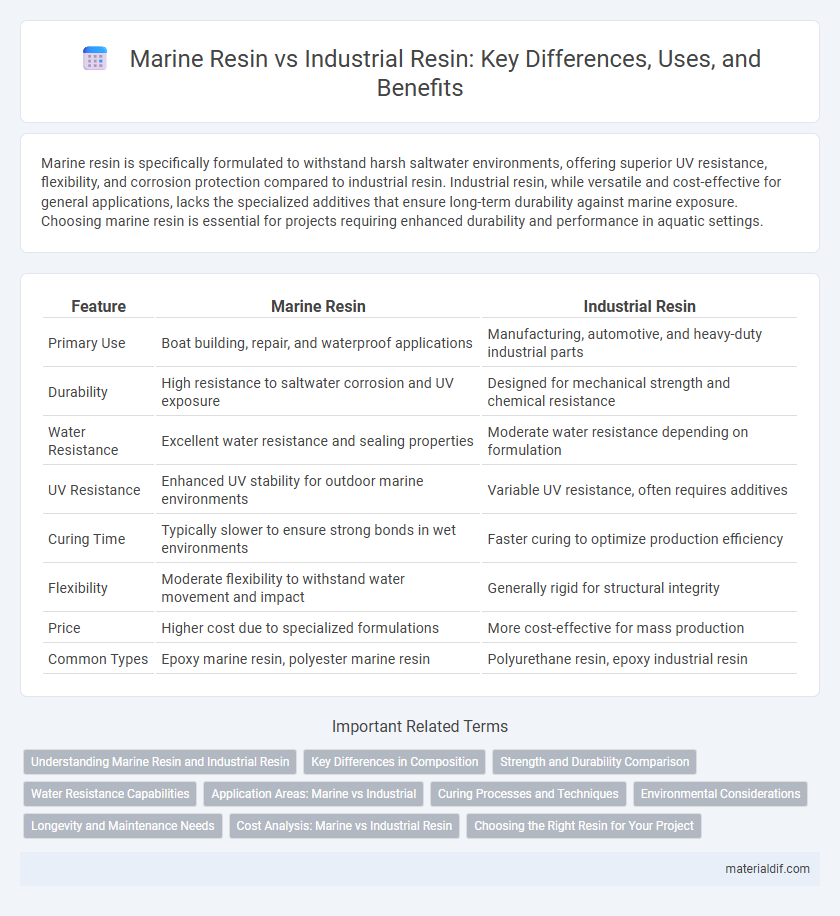

Table of Comparison

| Feature | Marine Resin | Industrial Resin |

|---|---|---|

| Primary Use | Boat building, repair, and waterproof applications | Manufacturing, automotive, and heavy-duty industrial parts |

| Durability | High resistance to saltwater corrosion and UV exposure | Designed for mechanical strength and chemical resistance |

| Water Resistance | Excellent water resistance and sealing properties | Moderate water resistance depending on formulation |

| UV Resistance | Enhanced UV stability for outdoor marine environments | Variable UV resistance, often requires additives |

| Curing Time | Typically slower to ensure strong bonds in wet environments | Faster curing to optimize production efficiency |

| Flexibility | Moderate flexibility to withstand water movement and impact | Generally rigid for structural integrity |

| Price | Higher cost due to specialized formulations | More cost-effective for mass production |

| Common Types | Epoxy marine resin, polyester marine resin | Polyurethane resin, epoxy industrial resin |

Understanding Marine Resin and Industrial Resin

Marine resin is specifically formulated to withstand harsh saline environments and UV exposure, making it ideal for boat building, repairs, and underwater applications. Industrial resin, on the other hand, offers enhanced chemical resistance, high strength, and thermal stability, serving a wide range of manufacturing and engineering purposes. Both resins are synthesized with distinct chemical properties to meet the unique demands of marine and industrial settings.

Key Differences in Composition

Marine resin typically contains UV stabilizers and enhanced corrosion resistance additives, making it suitable for harsh saltwater environments. Industrial resin, on the other hand, often prioritizes mechanical strength and chemical resistance with formulations tailored to withstand industrial pollutants and high temperatures. The key differences in composition lie in additives and polymer base, with marine resin optimized for durability against marine elements, while industrial resin focuses on robustness in manufacturing settings.

Strength and Durability Comparison

Marine resin typically offers superior strength and durability due to its formulation with UV inhibitors and anti-corrosive additives, making it highly resistant to saltwater and harsh marine environments. Industrial resin is generally designed for broad applications, lacking specialized features to withstand continuous exposure to moisture, chemicals, or extreme weather. The enhanced properties of marine resin ensure long-lasting performance and structural integrity in demanding aquatic conditions, whereas industrial resin may degrade faster under similar stresses.

Water Resistance Capabilities

Marine resin is specifically formulated with enhanced water resistance and UV stability, making it ideal for harsh marine environments where constant exposure to water and salt is a concern. Industrial resin, while durable, generally lacks the same level of waterproofing and corrosion resistance, limiting its effectiveness in prolonged wet conditions. High-performance marine resins often contain additives such as biocides and anti-corrosion agents to ensure long-lasting protection against moisture and environmental degradation.

Application Areas: Marine vs Industrial

Marine resin is specially formulated for harsh seawater environments, providing excellent durability, UV resistance, and water repellency, making it ideal for boat building, marine coatings, and underwater repairs. Industrial resin is engineered for a wide range of manufacturing applications, including electronics, automotive parts, and construction materials, where high mechanical strength, thermal stability, and chemical resistance are crucial. Both resins serve distinct purposes, with marine resin optimized for corrosion resistance and longevity in aquatic conditions, while industrial resin focuses on structural performance and versatility in diverse industrial settings.

Curing Processes and Techniques

Marine resin typically undergoes a slower, more controlled curing process to enhance water resistance, using specialized catalysts and additives to prevent bubbles and ensure durability in harsh sea environments. Industrial resin curing often prioritizes speed and efficiency, employing higher temperatures and accelerated hardeners to meet production demands while maintaining structural integrity. Techniques such as vacuum degassing and post-curing are common in both types to optimize mechanical properties and adhesion.

Environmental Considerations

Marine resin is specifically formulated to withstand harsh oceanic environments, often incorporating eco-friendly components to reduce toxicity and biodegrade more rapidly in marine ecosystems. Industrial resin, while versatile and durable for manufacturing, can contain chemical additives that pose greater risks to terrestrial and aquatic environments due to slower degradation rates and potential release of harmful substances. Choosing marine resin supports sustainable practices by minimizing ecological impact in sensitive marine habitats compared to conventional industrial resin options.

Longevity and Maintenance Needs

Marine resin is specifically formulated to withstand harsh saltwater environments, offering superior longevity through enhanced resistance to UV rays, moisture, and corrosion compared to industrial resin. Industrial resin often requires more frequent maintenance due to its lower tolerance to environmental stressors and potential for quicker degradation. Choosing marine resin significantly reduces upkeep costs and extends the lifespan of marine applications, making it the preferred option for durability and maintenance efficiency.

Cost Analysis: Marine vs Industrial Resin

Marine resin typically incurs higher costs compared to industrial resin due to its enhanced formulation that offers superior resistance to saltwater corrosion, UV exposure, and extreme weather conditions, which are critical for marine applications. Industrial resin is generally more affordable, designed for less demanding environments with relaxed performance requirements, making it a cost-effective choice for manufacturing processes and non-marine uses. The price differential reflects the balance between durability needs and budget constraints, with marine resin commanding premiums for specialized additives and certifications.

Choosing the Right Resin for Your Project

Marine resin offers superior water resistance, UV stability, and saltwater durability, making it ideal for boat building and marine applications. Industrial resin provides excellent chemical resistance and mechanical strength, suited for manufacturing, automotive parts, and heavy-duty equipment. Selecting the right resin depends on environmental exposure and performance requirements, ensuring longevity and structural integrity for your specific project.

Marine Resin vs Industrial Resin Infographic

materialdif.com

materialdif.com