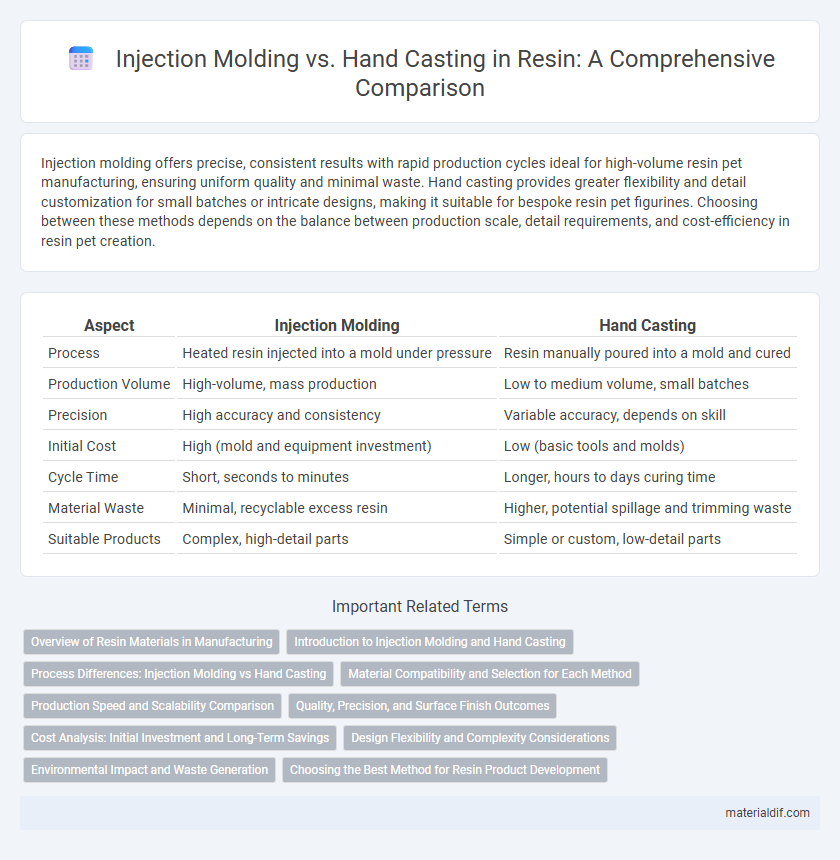

Injection molding offers precise, consistent results with rapid production cycles ideal for high-volume resin pet manufacturing, ensuring uniform quality and minimal waste. Hand casting provides greater flexibility and detail customization for small batches or intricate designs, making it suitable for bespoke resin pet figurines. Choosing between these methods depends on the balance between production scale, detail requirements, and cost-efficiency in resin pet creation.

Table of Comparison

| Aspect | Injection Molding | Hand Casting |

|---|---|---|

| Process | Heated resin injected into a mold under pressure | Resin manually poured into a mold and cured |

| Production Volume | High-volume, mass production | Low to medium volume, small batches |

| Precision | High accuracy and consistency | Variable accuracy, depends on skill |

| Initial Cost | High (mold and equipment investment) | Low (basic tools and molds) |

| Cycle Time | Short, seconds to minutes | Longer, hours to days curing time |

| Material Waste | Minimal, recyclable excess resin | Higher, potential spillage and trimming waste |

| Suitable Products | Complex, high-detail parts | Simple or custom, low-detail parts |

Overview of Resin Materials in Manufacturing

Resin materials used in manufacturing for injection molding typically include thermosetting plastics such as epoxy, polyester, and polyurethane, which offer high durability, chemical resistance, and precision in complex designs. Hand casting often utilizes RTV (room temperature vulcanizing) silicone resins or polyurethane resins, favored for their ease of use in small batches, flexibility, and ability to capture fine details without requiring expensive molds. The choice between injection molding and hand casting depends on production volume, material properties, and precision requirements, with injection molding suited for mass production and hand casting ideal for prototyping or low-volume custom parts.

Introduction to Injection Molding and Hand Casting

Injection molding involves injecting molten resin into a precisely designed mold under high pressure, enabling rapid production of complex and consistent parts with tight tolerances. Hand casting uses liquid resin poured manually into molds, offering greater flexibility for custom or low-volume pieces but with longer curing times and potential variability. Both methods use thermosetting or thermoplastic resins, but injection molding excels in mass production efficiency while hand casting is ideal for artisans and prototyping.

Process Differences: Injection Molding vs Hand Casting

Injection molding involves injecting molten resin into precise molds under high pressure, enabling rapid production of complex and detailed parts with consistent quality. Hand casting requires manually pouring resin into molds, resulting in slower production times and greater variability in finished product detail and consistency. Injection molding suits large-scale manufacturing, while hand casting is better aligned with small runs or custom, artisanal creations.

Material Compatibility and Selection for Each Method

Injection molding suits thermoplastic resins like ABS, polypropylene, and polystyrene due to their melt flow properties, enabling precise and repetitive shaping. Hand casting favors thermosetting resins such as epoxy, polyurethane, and polyester, which cure at room temperature and allow more intricate, low-volume production. Material selection depends on processing temperature tolerance, viscosity, and end-use mechanical properties specific to each manufacturing method.

Production Speed and Scalability Comparison

Injection molding offers significantly faster production speeds than hand casting, producing hundreds to thousands of resin parts per hour through automated, high-pressure injection processes. Hand casting is labor-intensive and slower, often requiring hours or days to cure individual resin pieces, limiting throughput. Scalability heavily favors injection molding, as it supports mass production with consistent quality, while hand casting is better suited for small batches or prototypes due to its manual nature and longer cycle times.

Quality, Precision, and Surface Finish Outcomes

Injection molding offers superior quality and precision due to its automated, repeatable process, ensuring consistent dimensions and intricate detail replication. Hand casting allows for more artistic flexibility but often results in variable surface finish and less uniformity in final products. The surface finish in injection molding is typically smoother and more refined, benefiting from polished molds and controlled cooling cycles.

Cost Analysis: Initial Investment and Long-Term Savings

Injection molding requires a significant initial investment in high-precision molds and specialized machinery, making it cost-effective primarily for large production runs. Hand casting involves lower upfront costs with minimal equipment expenses, suitable for small batches or custom pieces but can lead to higher per-unit costs over time. Long-term savings with injection molding arise from faster production cycles, material efficiency, and reduced labor costs compared to the labor-intensive hand casting process.

Design Flexibility and Complexity Considerations

Injection molding offers high precision and consistent replication for complex resin parts with intricate detailing, making it ideal for mass production and designs requiring tight tolerances. Hand casting excels in design flexibility, allowing for custom shapes and modifications without expensive molds, suitable for prototyping and low-volume or unique resin pieces. Choosing between the two depends on the balance between production volume, complexity of geometry, and need for detailed surface finishes in resin manufacturing.

Environmental Impact and Waste Generation

Injection molding of resin produces less waste due to high precision and material reuse, significantly reducing environmental impact compared to hand casting. Hand casting generates more excess resin and offcuts, leading to greater waste disposal challenges and higher resource consumption. Energy efficiency in injection molding further lowers carbon emissions, making it a more sustainable option for resin manufacturing.

Choosing the Best Method for Resin Product Development

Injection molding offers precise, high-volume resin product manufacturing with consistent quality and reduced labor costs, making it ideal for large-scale production. Hand casting provides flexibility for small batches, complex shapes, and rapid prototyping, enabling customization and lower initial investment. Selecting the best method depends on production volume, design complexity, and budget constraints to optimize resin product development.

Injection Molding vs Hand Casting Infographic

materialdif.com

materialdif.com