Heat-resistant resin offers superior thermal stability compared to standard resin, maintaining structural integrity at elevated temperatures up to 200degC or higher. Standard resin typically softens or deforms under heat, limiting its use in high-temperature applications. Choosing heat-resistant resin enhances durability and performance in automotive, aerospace, and electronic components exposed to extreme heat.

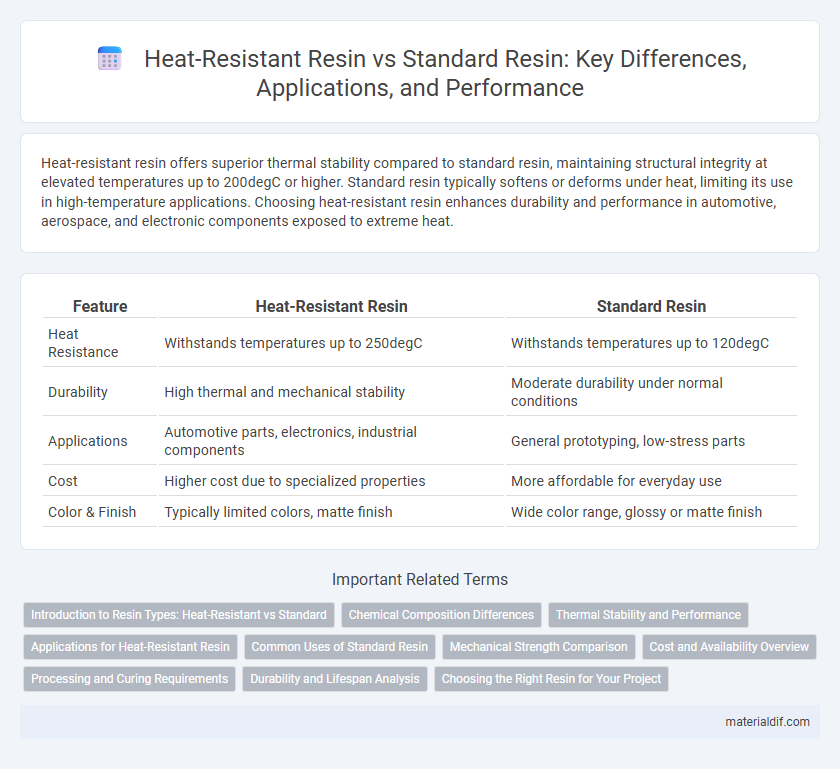

Table of Comparison

| Feature | Heat-Resistant Resin | Standard Resin |

|---|---|---|

| Heat Resistance | Withstands temperatures up to 250degC | Withstands temperatures up to 120degC |

| Durability | High thermal and mechanical stability | Moderate durability under normal conditions |

| Applications | Automotive parts, electronics, industrial components | General prototyping, low-stress parts |

| Cost | Higher cost due to specialized properties | More affordable for everyday use |

| Color & Finish | Typically limited colors, matte finish | Wide color range, glossy or matte finish |

Introduction to Resin Types: Heat-Resistant vs Standard

Heat-resistant resin offers superior thermal stability, maintaining structural integrity at temperatures up to 200degC, compared to standard resin which typically withstands around 80-120degC. This enhanced heat tolerance makes heat-resistant resin ideal for applications in automotive, aerospace, and electronics industries where exposure to elevated temperatures is common. Standard resin remains a cost-effective choice for general-purpose uses with lower thermal requirements, such as prototyping and decorative items.

Chemical Composition Differences

Heat-resistant resin contains aromatic rings and heat-stabilizing additives such as polyimides or polyphenylene sulfide, which enhance thermal stability and prevent degradation at high temperatures. Standard resin typically consists of aliphatic polymers like epoxy or polyester, which lack these reinforcing chemical structures and thus have lower thermal resistance. The inclusion of rigid, cross-linked molecular chains in heat-resistant resins contributes significantly to their superior chemical and thermal performance compared to standard resins.

Thermal Stability and Performance

Heat-resistant resin offers superior thermal stability compared to standard resin, maintaining structural integrity at temperatures exceeding 200degC. This enhanced performance ensures minimal deformation and improved mechanical properties under prolonged heat exposure. Standard resin typically softens or deforms at lower temperatures, limiting its application in high-heat environments.

Applications for Heat-Resistant Resin

Heat-resistant resin is engineered to withstand elevated temperatures, making it ideal for applications in automotive, aerospace, and electronics industries where thermal stability is crucial. Unlike standard resin, heat-resistant resin maintains mechanical integrity and dimensional stability under continuous heat exposure, enabling its use in engine components, electrical insulators, and heat exchangers. Its superior thermal properties extend the lifespan of parts subjected to high-temperature environments, enhancing safety and performance.

Common Uses of Standard Resin

Standard resin is commonly used in applications such as prototyping, decorative items, and basic mechanical parts due to its ease of processing and cost-effectiveness. It is ideal for low-stress environments like consumer products, toy manufacturing, and model making where high heat resistance is not required. Standard resin offers versatility in 3D printing, injection molding, and casting for everyday plastic components.

Mechanical Strength Comparison

Heat-resistant resin exhibits significantly higher mechanical strength compared to standard resin, maintaining structural integrity at elevated temperatures up to 200degC or more. Standard resin typically begins to degrade or soften around 70-90degC, leading to reduced durability and mechanical performance. This makes heat-resistant resin ideal for applications requiring sustained load-bearing capacity under thermal stress.

Cost and Availability Overview

Heat-resistant resin typically incurs higher costs compared to standard resin due to specialized additives that enhance thermal stability and performance in extreme temperatures. Standard resin remains more widely available and cost-effective, making it suitable for general applications where heat resistance is not critical. Availability of heat-resistant resin is more limited, often requiring orders from specialized suppliers with longer lead times.

Processing and Curing Requirements

Heat-resistant resin requires higher processing temperatures and extended curing times compared to standard resin to achieve optimal thermal stability and mechanical properties. Standard resin typically cures at lower temperatures with shorter cycle times, making it easier to process but less suitable for high-temperature applications. Precise control of temperature and curing conditions is critical in heat-resistant resin to prevent degradation and ensure long-term performance.

Durability and Lifespan Analysis

Heat-resistant resin offers superior durability compared to standard resin due to its enhanced thermal stability, maintaining structural integrity at temperatures exceeding 200degC. This advanced resin type exhibits a significantly longer lifespan, often lasting 2 to 3 times longer in high-temperature applications without warping or degradation. Standard resins typically soften or degrade around 60-80degC, leading to reduced mechanical performance and shorter service life in demanding environments.

Choosing the Right Resin for Your Project

Heat-resistant resin offers superior thermal stability, making it ideal for applications exposed to high temperatures or thermal cycling, such as automotive parts and electronic housings. Standard resin provides cost-effective solutions with adequate strength for general-purpose uses, but may deform or degrade under prolonged heat exposure. Selecting the right resin depends on the project's temperature requirements, mechanical stress, and durability expectations to ensure optimal performance and longevity.

Heat-Resistant Resin vs Standard Resin Infographic

materialdif.com

materialdif.com