Casting resin offers higher viscosity and slower curing times, making it ideal for creating thick, solid objects with minimal bubbles. Laminating resin has lower viscosity and faster curing properties, perfectly suited for coating surfaces and bonding layers in composites. Understanding the differences ensures optimal results for specific projects such as jewelry making or fiberglass repairs.

Table of Comparison

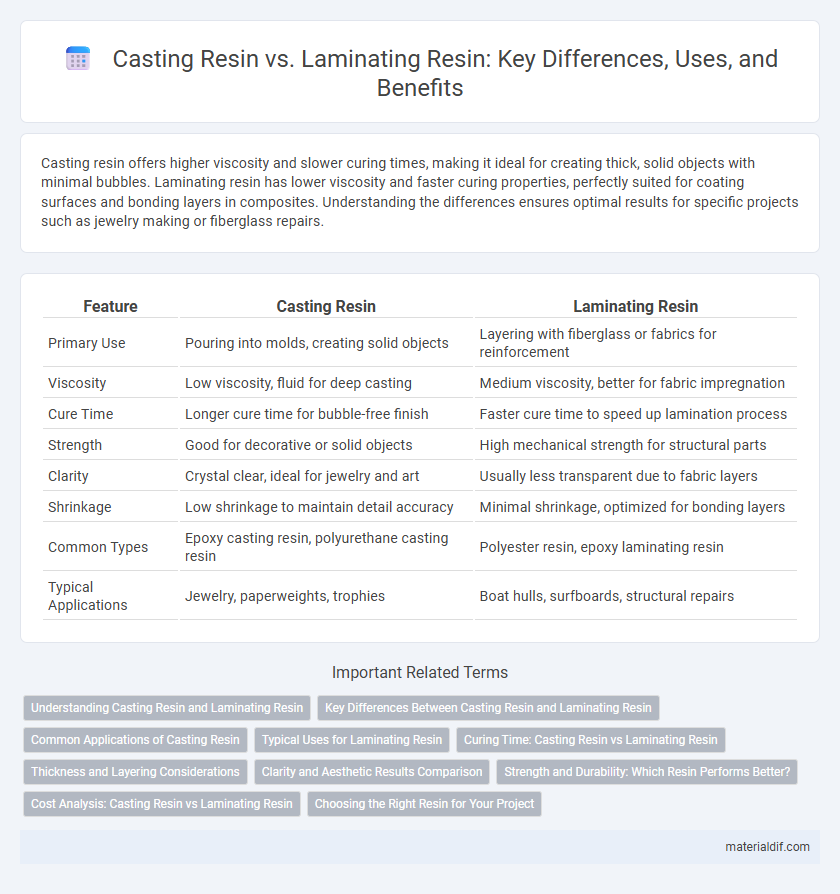

| Feature | Casting Resin | Laminating Resin |

|---|---|---|

| Primary Use | Pouring into molds, creating solid objects | Layering with fiberglass or fabrics for reinforcement |

| Viscosity | Low viscosity, fluid for deep casting | Medium viscosity, better for fabric impregnation |

| Cure Time | Longer cure time for bubble-free finish | Faster cure time to speed up lamination process |

| Strength | Good for decorative or solid objects | High mechanical strength for structural parts |

| Clarity | Crystal clear, ideal for jewelry and art | Usually less transparent due to fabric layers |

| Shrinkage | Low shrinkage to maintain detail accuracy | Minimal shrinkage, optimized for bonding layers |

| Common Types | Epoxy casting resin, polyurethane casting resin | Polyester resin, epoxy laminating resin |

| Typical Applications | Jewelry, paperweights, trophies | Boat hulls, surfboards, structural repairs |

Understanding Casting Resin and Laminating Resin

Casting resin is designed for deep pours and creating thick, solid objects with minimal heat generation, ideal for molds and sculptures. Laminating resin, often used in composites, cures quickly and provides a strong, flexible bond for layering materials like fiberglass. Understanding the different curing times, viscosities, and mechanical strengths of casting and laminating resins is crucial for selecting the right resin for specific projects.

Key Differences Between Casting Resin and Laminating Resin

Casting resin, designed for pouring into molds, offers excellent clarity and smooth finishes ideal for creating solid objects, while laminating resin is formulated for layering with fibrous materials like fiberglass to produce strong, flexible composites. Key differences include viscosity, with casting resin being low-viscosity for bubble-free casting, and laminating resin having higher viscosity to saturate reinforcement fabrics effectively. Cure time and mechanical properties also vary, as casting resin cures slower for clarity, whereas laminating resin cures faster for structural strength and durability.

Common Applications of Casting Resin

Casting resin is commonly used in jewelry making, art sculptures, and prototype modeling due to its ability to create thick, solid shapes without cracking. Its self-leveling properties and slow curing time make it ideal for embedding objects and creating clear, glossy finishes. Unlike laminating resin, which is primarily used for layering and reinforcing surfaces, casting resin excels in producing durable, free-standing pieces with intricate details.

Typical Uses for Laminating Resin

Laminating resin is primarily used for reinforcing fiberglass in boat building, automotive repairs, and surfboard manufacturing due to its strong bonding properties and flexibility. It provides excellent structural support and durability when combined with fiberglass cloth, creating lightweight, impact-resistant composites. Unlike casting resin, laminating resin cures with less shrinkage and forms a tougher, more resilient surface ideal for layers and overlays.

Curing Time: Casting Resin vs Laminating Resin

Casting resin typically has a longer curing time, ranging from 24 to 72 hours, allowing for a thicker pour without overheating or cracking. Laminating resin cures faster, often within 12 to 24 hours, which is essential for layering multiple thin coats in boat building and composite repairs. The curing speed affects project timelines and the resin's suitability for specific applications, with casting resin favored for deep casting and laminating resin preferred for surface finishes.

Thickness and Layering Considerations

Casting resin is designed for thick pours, allowing layers up to several centimeters without heat buildup or cracking, making it ideal for deep casts. Laminating resin is optimized for thin, multiple layers applied over surfaces, with each layer typically less than 1 millimeter to ensure proper curing and adhesion. Understanding the distinct thickness and layering capacities of casting versus laminating resin is crucial for achieving durability and clarity in resin projects.

Clarity and Aesthetic Results Comparison

Casting resin offers superior clarity and a glass-like finish, making it ideal for projects that require high transparency and detailed visual appeal. Laminating resin tends to have a slightly lower clarity, which can result in a more muted or frosted appearance, suited for protective coatings or layered composites rather than decorative pieces. The aesthetic outcomes with casting resin are typically sharper and more vibrant, enhancing the depth and color of embedded objects compared to laminating resin.

Strength and Durability: Which Resin Performs Better?

Casting resin typically offers greater strength and durability due to its thicker viscosity and slower curing process, allowing it to better withstand impacts and mechanical stresses. Laminating resin, although strong, is designed for layering and bonding fibers, providing enhanced flexibility but generally less impact resistance compared to casting resin. In applications demanding maximum structural integrity and long-term durability, casting resin outperforms laminating resin.

Cost Analysis: Casting Resin vs Laminating Resin

Casting resin typically incurs higher upfront costs due to its thicker viscosity and versatility in creating solid casts, whereas laminating resin offers a more economical option for large surface applications and layering with fiberglass. The cost efficiency of laminating resin becomes evident in projects requiring extensive coverage or reinforcement, as it spreads thinner and cures faster, reducing material usage and labor time. Evaluating project scale and detail level can optimize budget allocation, with casting resin preferred for intricate, solid forms and laminating resin for structural laminates and cost-effective large-scale work.

Choosing the Right Resin for Your Project

Casting resin provides excellent clarity and is ideal for thick pours and encapsulating objects, while laminating resin offers superior flexibility and adhesion for thin layers and surface coatings. Selecting the right resin depends on the project's requirements, such as depth, finish, and intended durability. Understanding the specific properties of casting and laminating resins ensures optimal results and long-lasting performance.

Casting Resin vs Laminating Resin Infographic

materialdif.com

materialdif.com