Polyurethane resin offers superior flexibility and abrasion resistance, making it ideal for coatings, adhesives, and sealants, while polycarbonate resin excels in impact resistance and optical clarity, commonly used in eyewear lenses and electronic components. Polyurethane resins typically have excellent chemical resistance but lower heat tolerance compared to polycarbonate resins, which withstand higher temperatures without deforming. Choosing between the two depends on application requirements such as mechanical strength, durability, and environmental exposure.

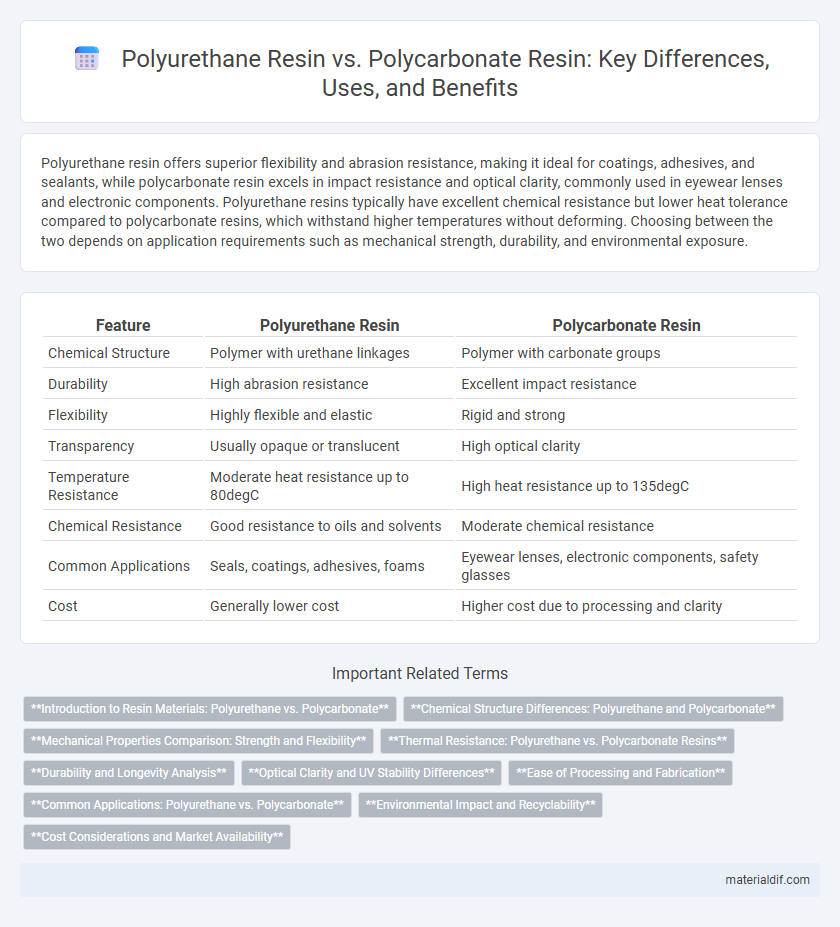

Table of Comparison

| Feature | Polyurethane Resin | Polycarbonate Resin |

|---|---|---|

| Chemical Structure | Polymer with urethane linkages | Polymer with carbonate groups |

| Durability | High abrasion resistance | Excellent impact resistance |

| Flexibility | Highly flexible and elastic | Rigid and strong |

| Transparency | Usually opaque or translucent | High optical clarity |

| Temperature Resistance | Moderate heat resistance up to 80degC | High heat resistance up to 135degC |

| Chemical Resistance | Good resistance to oils and solvents | Moderate chemical resistance |

| Common Applications | Seals, coatings, adhesives, foams | Eyewear lenses, electronic components, safety glasses |

| Cost | Generally lower cost | Higher cost due to processing and clarity |

Introduction to Resin Materials: Polyurethane vs. Polycarbonate

Polyurethane resin offers excellent flexibility, chemical resistance, and impact strength, making it ideal for coatings, adhesives, and flexible molds. Polycarbonate resin provides superior transparency, high impact resistance, and thermal stability, commonly used in optical lenses, automotive parts, and electronic components. Both resins serve diverse industrial applications with distinct mechanical and chemical properties tailored to specific performance requirements.

Chemical Structure Differences: Polyurethane and Polycarbonate

Polyurethane resin consists of repeating units formed by the reaction between polyols and diisocyanates, resulting in flexible urethane linkages characterized by carbamate groups (-NH-CO-O-). Polycarbonate resin, on the other hand, features carbonate groups (-O-(C=O)-O-) in its backbone, typically synthesized through the polycondensation of bisphenol A with phosgene, leading to rigid and transparent polymer chains. The presence of urethane linkages in polyurethane imparts elasticity and chemical resistance, while the carbonate linkages in polycarbonate contribute to high impact strength and thermal stability.

Mechanical Properties Comparison: Strength and Flexibility

Polyurethane resin exhibits exceptional flexibility and impact resistance, making it ideal for applications requiring cushioning and abrasion resistance. Polycarbonate resin offers superior tensile strength and rigidity, providing high structural integrity and dimensional stability under stress. Comparing mechanical properties, polyurethane is favored for elasticity, while polycarbonate excels in hardness and load-bearing capacity.

Thermal Resistance: Polyurethane vs. Polycarbonate Resins

Polycarbonate resin exhibits superior thermal resistance, maintaining structural integrity at temperatures up to 150degC, whereas polyurethane resin typically withstands up to 80-100degC before deforming. The higher glass transition temperature (Tg) of polycarbonate, around 147degC, contributes to its enhanced performance in heat-intensive applications. Polyurethane resins offer flexibility and impact resistance but are less suitable for environments requiring sustained high-temperature exposure compared to polycarbonate resins.

Durability and Longevity Analysis

Polyurethane resin demonstrates superior flexibility and impact resistance, making it highly durable in environments prone to mechanical stress, while polycarbonate resin excels with exceptional hardness and resistance to abrasion, providing long-term surface protection. Both resins offer excellent weathering resistance, but polyurethane typically outperforms in chemical resistance, enhancing longevity in harsh conditions. Polycarbonate's high thermal stability complements its toughness, ensuring sustained performance in elevated temperatures over extended periods.

Optical Clarity and UV Stability Differences

Polycarbonate resin exhibits superior optical clarity compared to polyurethane resin, making it ideal for applications requiring high transparency and minimal distortion. Polycarbonate also offers enhanced UV stability, resisting yellowing and degradation under prolonged sun exposure, whereas polyurethane resin tends to yellow and lose clarity when exposed to UV radiation. These differences make polycarbonate resin the preferred choice for optical lenses, protective shields, and outdoor applications demanding long-term durability and visual precision.

Ease of Processing and Fabrication

Polyurethane resin offers superior ease of processing due to its low viscosity and excellent moldability, allowing for quick curing and flexible shaping in various applications. Polycarbonate resin, while durable and impact-resistant, requires higher temperatures and more precise conditions for molding and fabrication, often necessitating specialized equipment. The simpler handling and faster cycle times of polyurethane resins make them ideal for rapid prototyping and complex component manufacturing.

Common Applications: Polyurethane vs. Polycarbonate

Polyurethane resin is widely used in flexible foams, coatings, adhesives, and sealants due to its excellent elasticity and abrasion resistance, making it ideal for automotive parts, footwear, and furniture. Polycarbonate resin is favored for applications requiring high impact resistance and optical clarity, such as eyewear lenses, electronic housings, and bullet-resistant windows. Both resins serve critical roles in manufacturing, with polyurethane excelling in cushioning and sealing while polycarbonate dominates in protective and transparent structural components.

Environmental Impact and Recyclability

Polyurethane resin generally has a higher environmental impact due to its synthesis from petroleum-based isocyanates and polyols, which are less biodegradable and pose challenges in recycling processes. Polycarbonate resin offers better recyclability options through chemical recycling methods that enable recovery of bisphenol A, reducing landfill waste and resource consumption. Sustainable practices favor polycarbonate resin for lower carbon footprint and enhanced circular economy potential compared to traditional polyurethane formulations.

Cost Considerations and Market Availability

Polyurethane resin generally offers a lower-cost option compared to polycarbonate resin, making it more attractive for budget-sensitive applications. Polycarbonate resin, while more expensive, provides superior impact resistance and durability, leading to higher market demand in high-performance industries. Market availability for polyurethane resin is broader due to its versatility and widespread use in coatings, adhesives, and foams, whereas polycarbonate resin is primarily available through specialized suppliers catering to automotive and electronic sectors.

Polyurethane resin vs Polycarbonate resin Infographic

materialdif.com

materialdif.com