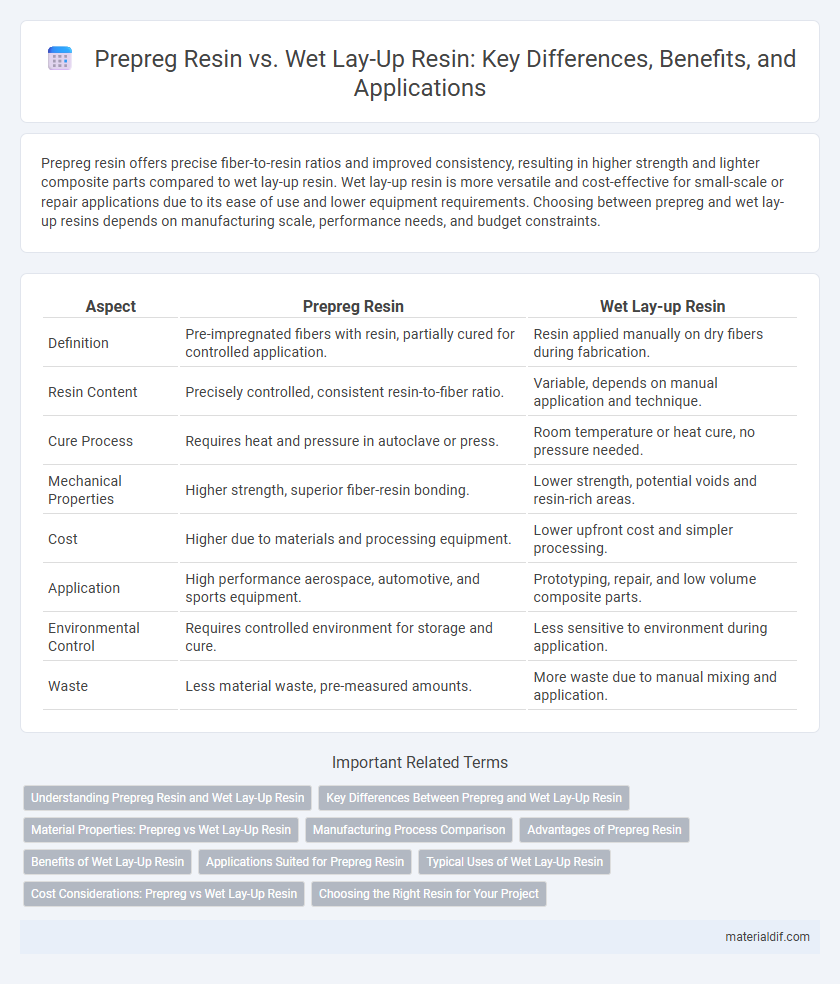

Prepreg resin offers precise fiber-to-resin ratios and improved consistency, resulting in higher strength and lighter composite parts compared to wet lay-up resin. Wet lay-up resin is more versatile and cost-effective for small-scale or repair applications due to its ease of use and lower equipment requirements. Choosing between prepreg and wet lay-up resins depends on manufacturing scale, performance needs, and budget constraints.

Table of Comparison

| Aspect | Prepreg Resin | Wet Lay-up Resin |

|---|---|---|

| Definition | Pre-impregnated fibers with resin, partially cured for controlled application. | Resin applied manually on dry fibers during fabrication. |

| Resin Content | Precisely controlled, consistent resin-to-fiber ratio. | Variable, depends on manual application and technique. |

| Cure Process | Requires heat and pressure in autoclave or press. | Room temperature or heat cure, no pressure needed. |

| Mechanical Properties | Higher strength, superior fiber-resin bonding. | Lower strength, potential voids and resin-rich areas. |

| Cost | Higher due to materials and processing equipment. | Lower upfront cost and simpler processing. |

| Application | High performance aerospace, automotive, and sports equipment. | Prototyping, repair, and low volume composite parts. |

| Environmental Control | Requires controlled environment for storage and cure. | Less sensitive to environment during application. |

| Waste | Less material waste, pre-measured amounts. | More waste due to manual mixing and application. |

Understanding Prepreg Resin and Wet Lay-Up Resin

Prepreg resin consists of pre-impregnated fibers with a precisely measured amount of thermoset resin, offering superior consistency, enhanced mechanical properties, and reduced waste compared to traditional wet lay-up resin. Wet lay-up resin requires manual application by saturating dry fibers on-site, allowing greater flexibility but often resulting in variable resin-to-fiber ratios and longer curing times. Understanding the distinctions in curing processes, resin content, and application methods is crucial for selecting the optimal resin system for composite manufacturing and structural performance.

Key Differences Between Prepreg and Wet Lay-Up Resin

Prepreg resin is a pre-impregnated composite fiber material with a precise resin-to-fiber ratio, offering superior control over fiber alignment and resin content, which enhances mechanical properties and consistency. Wet lay-up resin involves manually saturating dry fibers with resin, resulting in a less controlled resin distribution and potential for air pockets, impacting overall strength and finish quality. Prepreg systems require refrigeration and curing under heat and pressure, while wet lay-up methods cure at room temperature with simpler equipment, influencing production speed and cost.

Material Properties: Prepreg vs Wet Lay-Up Resin

Prepreg resin exhibits superior material properties such as higher fiber-to-resin ratios and enhanced consistency, resulting in improved strength, stiffness, and reduced void content compared to wet lay-up resin. Wet lay-up resin typically offers greater versatility and ease of application but may lead to variable laminate quality due to manual resin impregnation and potential air entrapment. The controlled cure cycle and optimized resin formulation in prepreg systems contribute to elevated thermal resistance and fatigue performance relative to traditional wet lay-up composites.

Manufacturing Process Comparison

Prepreg resin involves a controlled manufacturing process where fibers are pre-impregnated with resin under precise temperature and pressure conditions, ensuring uniform resin distribution and consistent curing. Wet lay-up resin manufacturing requires manual application of resin onto dry fibers, allowing flexibility but resulting in variable resin-to-fiber ratios and potential inconsistencies. The automated curing cycle in prepreg resins enhances mechanical properties and reduces void content compared to the more labor-intensive and less controlled wet lay-up process.

Advantages of Prepreg Resin

Prepreg resin offers superior fiber-to-resin ratio control, resulting in enhanced mechanical properties and consistency compared to wet lay-up resin. Its pre-impregnated fabric form ensures reduced void content and improved curing precision, leading to higher strength and durability in composite structures. The automated application process of prepreg resin also minimizes waste and operator variability, optimizing production efficiency.

Benefits of Wet Lay-Up Resin

Wet lay-up resin offers greater flexibility and ease of application compared to prepreg resin, making it ideal for complex or large-scale composite manufacturing. It provides excellent adhesion and can be used in various environmental conditions without requiring refrigeration. This resin type also reduces overall production costs due to its simpler storage and handling requirements.

Applications Suited for Prepreg Resin

Prepreg resin is ideal for high-performance applications requiring precise fiber-to-resin ratios and superior mechanical properties, such as aerospace, automotive racing, and advanced sporting goods manufacturing. Its pre-impregnated fiber format ensures consistent resin distribution and enables better control over curing cycles, which results in improved strength and reduced void content. This resin type excels in complex, lightweight composite structures demanding high strength-to-weight ratios and thermal stability.

Typical Uses of Wet Lay-Up Resin

Wet lay-up resin is typically used in large-scale composite manufacturing such as boat hulls, wind turbine blades, and automotive body panels due to its ease of application and cost-effectiveness. This resin system is ideal for manual lamination processes where flexibility and quick curing times are essential. It is favored in repair work and prototype development where vacuum-bagging or infusion techniques are not practical.

Cost Considerations: Prepreg vs Wet Lay-Up Resin

Prepreg resin generally incurs higher upfront costs due to its advanced manufacturing process and precise resin-to-fiber ratio, making it ideal for high-performance applications. Wet lay-up resin is more cost-effective, with lower material and processing expenses, suitable for larger or less critical projects where budget constraints are significant. Evaluating project requirements alongside cost considerations ensures optimal resin selection for efficiency and performance.

Choosing the Right Resin for Your Project

Prepreg resin offers enhanced fiber impregnation with superior control over resin-to-fiber ratios, resulting in higher strength-to-weight ratios and reduced void content, making it ideal for aerospace and high-performance applications. Wet lay-up resin provides flexibility and ease of use for large, complex shapes where quality control is less stringent, best suited for marine and automotive repairs with slower cure times. Evaluating project requirements such as mechanical properties, production volume, and curing conditions is essential for choosing between prepreg and wet lay-up resins.

Prepreg resin vs Wet lay-up resin Infographic

materialdif.com

materialdif.com