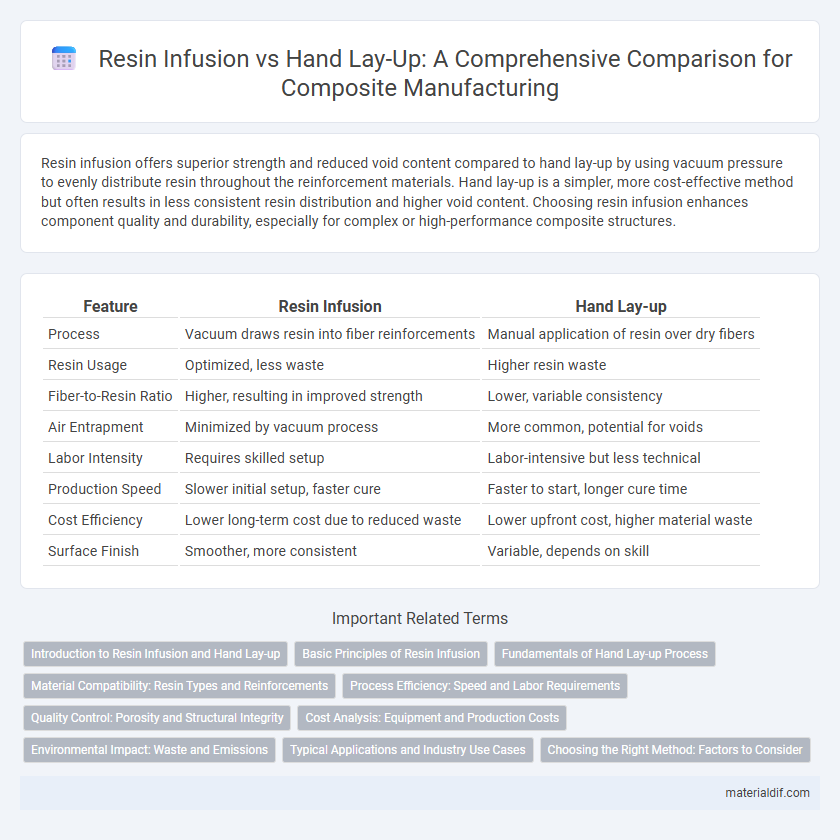

Resin infusion offers superior strength and reduced void content compared to hand lay-up by using vacuum pressure to evenly distribute resin throughout the reinforcement materials. Hand lay-up is a simpler, more cost-effective method but often results in less consistent resin distribution and higher void content. Choosing resin infusion enhances component quality and durability, especially for complex or high-performance composite structures.

Table of Comparison

| Feature | Resin Infusion | Hand Lay-up |

|---|---|---|

| Process | Vacuum draws resin into fiber reinforcements | Manual application of resin over dry fibers |

| Resin Usage | Optimized, less waste | Higher resin waste |

| Fiber-to-Resin Ratio | Higher, resulting in improved strength | Lower, variable consistency |

| Air Entrapment | Minimized by vacuum process | More common, potential for voids |

| Labor Intensity | Requires skilled setup | Labor-intensive but less technical |

| Production Speed | Slower initial setup, faster cure | Faster to start, longer cure time |

| Cost Efficiency | Lower long-term cost due to reduced waste | Lower upfront cost, higher material waste |

| Surface Finish | Smoother, more consistent | Variable, depends on skill |

Introduction to Resin Infusion and Hand Lay-up

Resin infusion is a closed-mold composite manufacturing process that uses vacuum pressure to draw resin into a fiber lay-up, ensuring thorough saturation and reducing voids for superior structural integrity. Hand lay-up is an open-mold technique involving manually applying resin onto fiber reinforcements by brush or roller, offering flexibility but often resulting in higher resin consumption and potential inconsistencies. Resin infusion provides enhanced fiber-to-resin ratios and better control over laminate thickness compared to traditional hand lay-up methods.

Basic Principles of Resin Infusion

Resin infusion involves drawing resin into a dry fiber lay-up using vacuum pressure, ensuring complete wet-out and minimal voids, which enhances structural integrity. Unlike hand lay-up, where resin is manually applied to fibers, resin infusion provides precise control over resin distribution and reduces excess resin, leading to lighter and stronger composites. This method increases manufacturing consistency and improves mechanical properties due to better fiber-to-resin ratios and reduced air entrapment.

Fundamentals of Hand Lay-up Process

The hand lay-up process involves manually placing reinforcement fibers into a mold and applying resin by brush or roller, allowing precise control over fiber orientation and resin distribution. This method is fundamental for its simplicity, low equipment cost, and versatility across small-to-medium scale composite production. Despite its labor-intensive nature, hand lay-up ensures detailed customization and is ideal for prototyping or parts with complex geometry.

Material Compatibility: Resin Types and Reinforcements

Resin infusion offers superior material compatibility by allowing the use of a wide range of resin types, including epoxy, vinyl ester, and polyester, which effectively impregnate reinforcements like carbon fiber, fiberglass, and Kevlar with minimal voids. Hand lay-up relies heavily on manual resin application, often leading to inconsistent wet-out and limited compatibility with advanced resin systems and high-performance reinforcements. The controlled vacuum environment of resin infusion ensures optimal resin-to-fiber ratios, enhancing mechanical properties and durability across various composite material combinations.

Process Efficiency: Speed and Labor Requirements

Resin infusion offers superior process efficiency compared to hand lay-up by significantly reducing labor intensity and cycle times through the use of vacuum pressure to draw resin into the fiber reinforcement. This automated method enhances speed by enabling uniform resin distribution and minimizing manual handling, which lowers the risk of defects and labor costs. Hand lay-up remains labor-intensive and slower, requiring skilled operators to manually apply resin and fabric, resulting in higher variability and longer production cycles.

Quality Control: Porosity and Structural Integrity

Resin infusion offers superior quality control compared to hand lay-up by significantly reducing porosity through vacuum-assisted resin flow, resulting in enhanced structural integrity and consistent fiber-to-resin ratios. Hand lay-up often leads to higher risks of voids and air entrapment due to manual resin application, which compromises mechanical properties and durability. Advanced resin infusion techniques ensure uniform resin distribution and minimize defects, making them ideal for high-performance composite manufacturing.

Cost Analysis: Equipment and Production Costs

Resin infusion generally requires higher initial equipment investment, including vacuum pumps, hoses, and vacuum bags, leading to increased upfront costs compared to the simpler, lower-cost tools used in hand lay-up processes. Production costs tend to be lower for resin infusion due to reduced labor intensity and material waste, while hand lay-up involves more manual labor and higher resin consumption, increasing ongoing expenses. Efficiency gains in resin infusion often result in better fiber-to-resin ratios and consistent quality, which can offset the higher equipment costs over time.

Environmental Impact: Waste and Emissions

Resin infusion generates significantly less waste compared to hand lay-up due to its controlled resin distribution and reduced excess material usage. The closed mold process in resin infusion minimizes volatile organic compound (VOC) emissions, enhancing environmental safety. Conversely, hand lay-up often produces higher emissions and more scrap material, leading to greater environmental impact.

Typical Applications and Industry Use Cases

Resin infusion is widely used in aerospace, automotive, and marine industries for manufacturing large, complex composite parts that require high strength-to-weight ratios and minimal void content. Hand lay-up is typically employed in small-scale production and prototyping within construction, custom boat building, and art industries due to its cost-effectiveness and simplicity. While resin infusion offers superior mechanical properties for critical structural components, hand lay-up remains preferred for applications where flexibility and low tooling costs are essential.

Choosing the Right Method: Factors to Consider

Selecting between resin infusion and hand lay-up depends primarily on factors such as project scale, desired mechanical properties, and labor skill level. Resin infusion offers superior fiber-to-resin ratios and reduced void content, making it ideal for high-performance composite components and complex geometries. Hand lay-up is preferable for lower volume production or prototypes where cost efficiency and flexibility outweigh advanced material properties.

Resin Infusion vs Hand Lay-up Infographic

materialdif.com

materialdif.com