Bisphenol-A epoxy resins offer excellent mechanical strength and chemical resistance, making them suitable for industrial coatings and adhesives. Bisphenol-F epoxy resins provide lower viscosity and improved electrical insulation properties, which enhance processability and performance in electronic applications. Choosing between Bisphenol-A and Bisphenol-F epoxy depends on specific application requirements such as durability, curing conditions, and thermal stability.

Table of Comparison

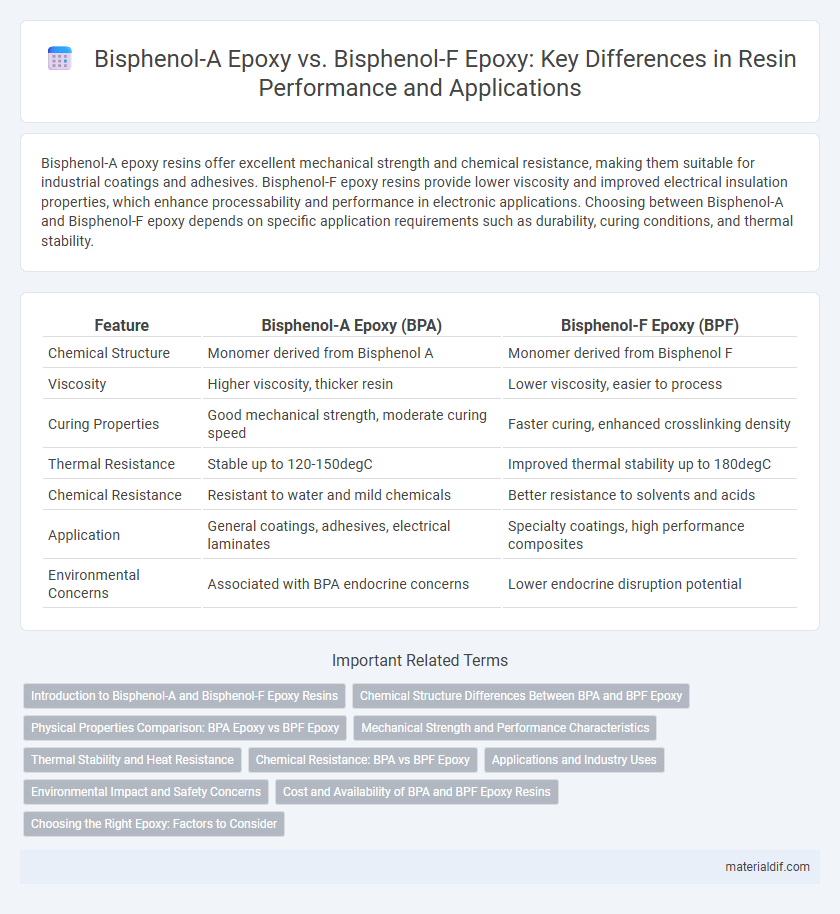

| Feature | Bisphenol-A Epoxy (BPA) | Bisphenol-F Epoxy (BPF) |

|---|---|---|

| Chemical Structure | Monomer derived from Bisphenol A | Monomer derived from Bisphenol F |

| Viscosity | Higher viscosity, thicker resin | Lower viscosity, easier to process |

| Curing Properties | Good mechanical strength, moderate curing speed | Faster curing, enhanced crosslinking density |

| Thermal Resistance | Stable up to 120-150degC | Improved thermal stability up to 180degC |

| Chemical Resistance | Resistant to water and mild chemicals | Better resistance to solvents and acids |

| Application | General coatings, adhesives, electrical laminates | Specialty coatings, high performance composites |

| Environmental Concerns | Associated with BPA endocrine concerns | Lower endocrine disruption potential |

Introduction to Bisphenol-A and Bisphenol-F Epoxy Resins

Bisphenol-A epoxy resins are thermosetting polymers derived from bisphenol-A and epichlorohydrin, known for their high mechanical strength and excellent chemical resistance. Bisphenol-F epoxy resins, synthesized from bisphenol-F and epichlorohydrin, exhibit lower viscosity and improved curing characteristics, making them ideal for applications requiring better flow and adhesion. Both resins serve as essential materials in coatings, adhesives, and composite manufacturing, with bisphenol-F often preferred for electrical insulation and high-performance industrial uses.

Chemical Structure Differences Between BPA and BPF Epoxy

Bisphenol-A (BPA) epoxy resins feature two methyl groups attached to the central carbon atom in their chemical structure, providing higher rigidity and thermal stability compared to Bisphenol-F (BPF) epoxy resins, which lack these methyl groups and instead have a simpler phenolic structure. The absence of methyl groups in BPF epoxy results in lower viscosity and better flexibility, enhancing their processability in coating and adhesive applications. These structural variations directly influence mechanical properties, curing behavior, and environmental resistance, making BPA epoxy preferred for demanding industrial uses while BPF epoxy offers advantages in formulations requiring improved flow and reduced brittleness.

Physical Properties Comparison: BPA Epoxy vs BPF Epoxy

Bisphenol-A (BPA) epoxy resins exhibit higher viscosity and better adhesion properties compared to Bisphenol-F (BPF) epoxy, making BPA ideal for coatings and adhesives requiring strong bonding. BPF epoxy resins provide lower viscosity and improved chemical resistance, enhancing processing ease and durability in harsh environments. Thermal stability and mechanical strength are comparable, though BPF resins often offer enhanced flexibility due to their molecular structure.

Mechanical Strength and Performance Characteristics

Bisphenol-A epoxy exhibits high mechanical strength with excellent adhesion and superior resistance to cracking under stress, making it ideal for structural applications. Bisphenol-F epoxy offers improved chemical resistance and lower viscosity, which enhances curing performance and results in a tougher, more impact-resistant finish. The choice between Bisphenol-A and Bisphenol-F epoxy impacts durability and performance, with Bisphenol-F often preferred for applications requiring enhanced toughness and flexibility.

Thermal Stability and Heat Resistance

Bisphenol-A epoxy resins exhibit high thermal stability and heat resistance, maintaining structural integrity at temperatures up to approximately 150degC, making them suitable for electrical and automotive applications. Bisphenol-F epoxy resins generally offer superior thermal resistance, withstanding temperatures beyond 180degC due to their lower molecular weight and more flexible polymer chains. The choice between Bisphenol-A and Bisphenol-F epoxies depends on specific thermal performance requirements and application environments.

Chemical Resistance: BPA vs BPF Epoxy

Bisphenol-A (BPA) epoxy resins exhibit strong chemical resistance against acids, alkalis, and solvents, making them suitable for harsh industrial environments. Bisphenol-F (BPF) epoxy resins offer superior resistance to high temperatures and improved chemical stability, especially against hydrocarbon-based chemicals and water absorption. The choice between BPA and BPF epoxy hinges on the specific chemical exposure and operating conditions, with BPF often preferred for applications demanding enhanced durability and lower viscosity.

Applications and Industry Uses

Bisphenol-A epoxy resins are extensively used in coatings, adhesives, and composite materials due to their strong mechanical properties and chemical resistance, making them ideal for automotive, electronics, and construction industries. Bisphenol-F epoxy resins offer lower viscosity and enhanced chemical resistance, which is preferred in electrical laminates, marine coatings, and high-performance composites where superior fluidity and durability are critical. Both resins find applications in aerospace and industrial flooring, but Bisphenol-F epoxies are favored for formulations requiring improved toughness and heat resistance.

Environmental Impact and Safety Concerns

Bisphenol-A (BPA) epoxy resins have been linked to higher environmental toxicity and endocrine disruption risks compared to Bisphenol-F (BPF) epoxy resins, which exhibit lower estrogenic activity and reduced leaching of harmful substances. The manufacturing and disposal processes of BPA-based resins release more persistent organic pollutants, increasing ecological harm and potential bioaccumulation. Safety concerns favor BPF epoxy due to its comparatively safer chemical profile, making it a preferred alternative in applications requiring stringent environmental and health standards.

Cost and Availability of BPA and BPF Epoxy Resins

Bisphenol-A (BPA) epoxy resins are generally more cost-effective and widely available due to their established production processes and extensive market presence. Bisphenol-F (BPF) epoxy resins typically incur higher costs and limited availability because of more complex manufacturing and niche applications. Supply chain stability favors BPA epoxy, making it the preferred choice for large-scale industrial use where budget constraints and material accessibility are critical.

Choosing the Right Epoxy: Factors to Consider

Choosing between Bisphenol-A (BPA) epoxy and Bisphenol-F (BPF) epoxy depends on factors like temperature resistance, chemical stability, and mechanical strength. BPA epoxy offers strong adhesion and durability for general applications, while BPF epoxy provides superior thermal stability and lower viscosity for high-performance uses. Consider the specific environmental conditions and application requirements to determine the optimal resin type for your project.

Bisphenol-A Epoxy vs Bisphenol-F Epoxy Infographic

materialdif.com

materialdif.com