3D printing resin is designed for rapid prototyping and detailed model creation, offering a smooth finish and high precision ideal for intricate designs. Jewelry resin, on the other hand, is formulated to provide superior durability, clarity, and a polished appearance suitable for casting and long-lasting wear. Selecting the right resin depends on the application requirements, with 3D printing resin excelling in detail and jewelry resin prioritizing strength and aesthetic quality.

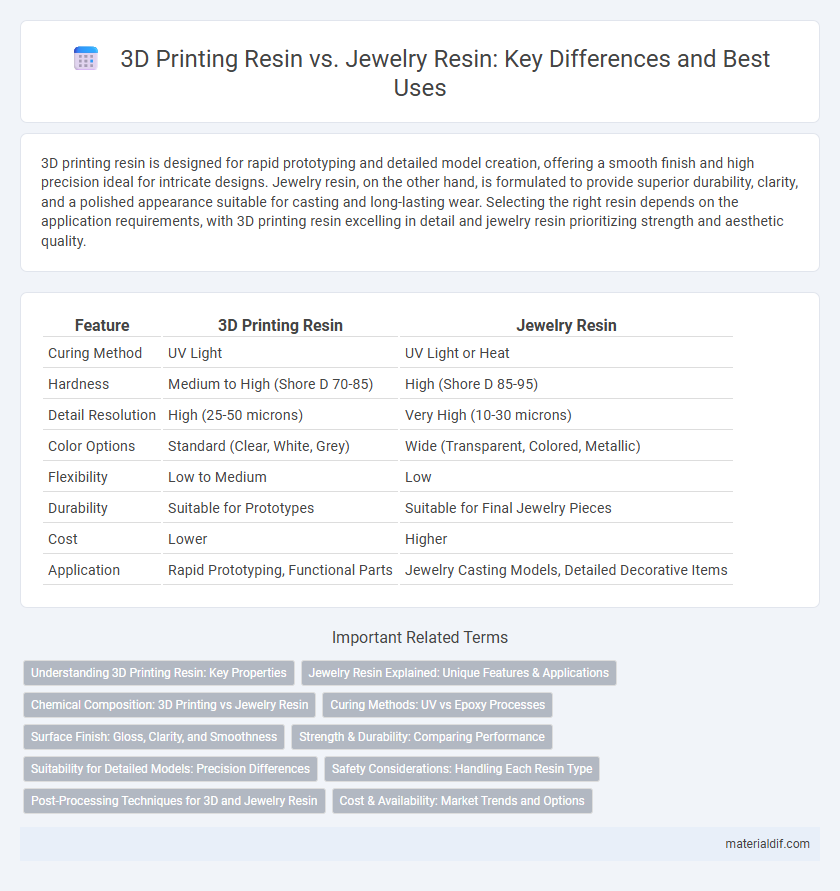

Table of Comparison

| Feature | 3D Printing Resin | Jewelry Resin |

|---|---|---|

| Curing Method | UV Light | UV Light or Heat |

| Hardness | Medium to High (Shore D 70-85) | High (Shore D 85-95) |

| Detail Resolution | High (25-50 microns) | Very High (10-30 microns) |

| Color Options | Standard (Clear, White, Grey) | Wide (Transparent, Colored, Metallic) |

| Flexibility | Low to Medium | Low |

| Durability | Suitable for Prototypes | Suitable for Final Jewelry Pieces |

| Cost | Lower | Higher |

| Application | Rapid Prototyping, Functional Parts | Jewelry Casting Models, Detailed Decorative Items |

Understanding 3D Printing Resin: Key Properties

3D printing resin is formulated for precision and rapid curing, offering high dimensional accuracy and smooth surface finishes essential for intricate designs. Jewelry resin, while also UV-curable, emphasizes optical clarity, durability, and the ability to capture fine details for polished, gemstone-like results. Understanding the key properties such as viscosity, curing speed, and hardness is crucial for selecting the right resin tailored to specific application needs.

Jewelry Resin Explained: Unique Features & Applications

Jewelry resin offers superior clarity, high hardness, and excellent detail resolution tailored for intricate designs, unlike standard 3D printing resins that prioritize faster curing and mechanical strength. Its specialized formulation includes additives that enhance polishability and UV stability, making it ideal for producing delicate, durable jewelry pieces. These unique features enable jewelers to create lifelike prototypes, bespoke rings, and detailed pendants with exceptional surface finish and color fidelity.

Chemical Composition: 3D Printing vs Jewelry Resin

3D printing resin primarily contains photopolymerizable acrylates or epoxies designed for rapid curing under UV light, ensuring precise layer-by-layer solidification. Jewelry resin often incorporates higher-quality epoxy or polyurethane bases mixed with pigments and additives for enhanced durability, flexibility, and clarity tailored to fine detail and polish. The chemical composition differences affect properties like viscosity, hardness, and curing time, with 3D printing resin optimized for mechanical strength and fast processing, while jewelry resin prioritizes aesthetic finish and long-term wear resistance.

Curing Methods: UV vs Epoxy Processes

3D printing resin cures primarily through ultraviolet (UV) light exposure, enabling rapid solidification layer by layer with high detail precision, ideal for additive manufacturing processes. Jewelry resin typically uses epoxy curing methods involving chemical reactions between resin and hardener, resulting in a tougher, more durable finish suitable for intricate decorative pieces. UV curing offers faster processing times and finer resolution, while epoxy curing provides enhanced strength and a glossy, polished appearance preferred in jewelry applications.

Surface Finish: Gloss, Clarity, and Smoothness

3D printing resin typically offers a smooth surface finish with moderate gloss and clarity, suitable for functional prototypes and detailed models. Jewelry resin features higher clarity and a glass-like gloss, enabling intricate designs to achieve a polished, gem-quality appearance. The smoothness of jewelry resin surpasses standard 3D printing resin, minimizing post-processing and enhancing the final aesthetic of fine jewelry pieces.

Strength & Durability: Comparing Performance

3D printing resin offers high precision but typically lacks the long-term strength and durability required for wearable jewelry, making it ideal for prototypes and detailed models. Jewelry resin is formulated with enhanced toughness and flexibility, ensuring resistance to cracking, chipping, and daily wear, which extends the longevity of finished jewelry pieces. The performance difference lies in jewelry resin's superior durability under stress, while 3D printing resin prioritizes fine details over mechanical resilience.

Suitability for Detailed Models: Precision Differences

3D printing resin offers higher precision ideal for producing intricate, highly detailed models with smooth surface finishes due to its fine particle composition and controlled curing process. Jewelry resin, while also capable of capturing details, typically prioritizes a balance between durability and flexibility, making it suitable for wearable pieces that require some resilience rather than ultra-fine detailing. Precision differences stem from the resin's formulation and viscosity, with 3D printing resin providing superior resolution for complex geometries compared to standard jewelry-grade resins.

Safety Considerations: Handling Each Resin Type

3D printing resin requires careful handling due to its potential skin irritation and toxic fumes, necessitating the use of gloves, masks, and well-ventilated areas. Jewelry resin, formulated with additives for finer detail and durability, often contains different chemical compounds that may trigger allergic reactions or respiratory issues without proper protective equipment. Both resin types demand strict adherence to safety protocols, including avoiding direct skin contact and ensuring thorough curing to minimize harmful exposure.

Post-Processing Techniques for 3D and Jewelry Resin

Post-processing techniques for 3D printing resin typically involve washing the printed model in isopropyl alcohol followed by UV curing to enhance strength and durability. Jewelry resin requires delicate sanding, polishing, and often a clear coat finish to achieve a smooth, glossy surface that highlights intricate details and gemstones. Both resins benefit from careful removal of supports and fine-tuning with tools like rotary brushes or micro-files to ensure high-quality final pieces.

Cost & Availability: Market Trends and Options

3D printing resin generally offers a lower cost per liter and greater availability, driven by high demand from industries such as prototyping and manufacturing, resulting in numerous budget-friendly options and widespread distribution. Jewelry resin, often formulated with higher clarity, durability, and specific curing properties, tends to be more expensive and less widely available, primarily supplied by niche vendors targeting artisans and jewelers. Market trends indicate increasing diversification of resin types, but 3D printing resin maintains broader market presence due to scalability and affordability, while jewelry resin remains a specialized product with premium pricing.

3D Printing Resin vs Jewelry Resin Infographic

materialdif.com

materialdif.com