Doming resin is specifically formulated to create thick, domed layers that enhance the visual depth and protect items like jewelry and decals, while coating resin is designed for creating smooth, even surface finishes on larger flat areas. Doming resin typically has a higher viscosity to maintain its shape without spreading, whereas coating resin has a lower viscosity for easy leveling and thin, uniform coverage. Choosing between doming resin and coating resin depends on the desired texture, thickness, and application area for optimal results.

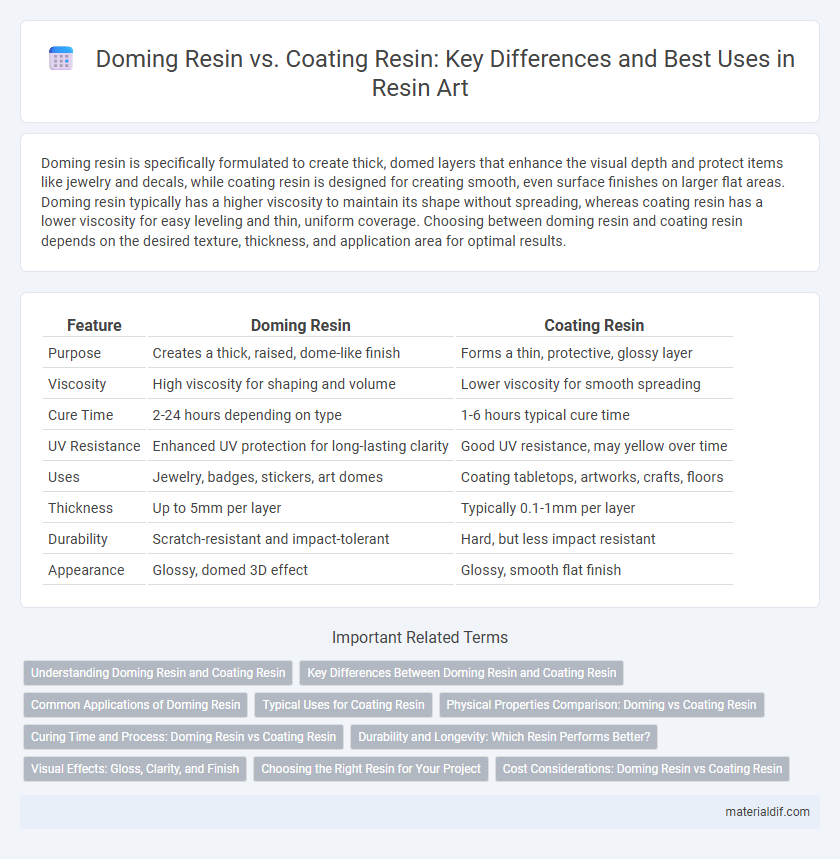

Table of Comparison

| Feature | Doming Resin | Coating Resin |

|---|---|---|

| Purpose | Creates a thick, raised, dome-like finish | Forms a thin, protective, glossy layer |

| Viscosity | High viscosity for shaping and volume | Lower viscosity for smooth spreading |

| Cure Time | 2-24 hours depending on type | 1-6 hours typical cure time |

| UV Resistance | Enhanced UV protection for long-lasting clarity | Good UV resistance, may yellow over time |

| Uses | Jewelry, badges, stickers, art domes | Coating tabletops, artworks, crafts, floors |

| Thickness | Up to 5mm per layer | Typically 0.1-1mm per layer |

| Durability | Scratch-resistant and impact-tolerant | Hard, but less impact resistant |

| Appearance | Glossy, domed 3D effect | Glossy, smooth flat finish |

Understanding Doming Resin and Coating Resin

Doming resin is a thick, self-leveling epoxy or polyurethane used to create a raised, glossy, and protective dome over surfaces such as labels, jewelry, and signage; it provides enhanced depth and a three-dimensional effect. Coating resin, typically a thinner epoxy or polyester formulation, is designed to cover larger surfaces evenly, offering a smooth, durable finish ideal for tabletops, bars, and art pieces. Both resins cure to a hard, transparent surface but differ in viscosity and application methods, with doming resin emphasizing aesthetic elevation and coating resin focusing on comprehensive surface protection.

Key Differences Between Doming Resin and Coating Resin

Doming resin is specifically formulated for creating thick, rounded, dome-shaped layers on surfaces, offering high clarity and UV resistance, ideal for decorative applications like jewelry or badges. Coating resin is designed for thin, smooth, protective layers on flat surfaces, emphasizing self-leveling and minimal bubbles to safeguard artwork or tabletops. Key differences include viscosity levels, curing times, and durability properties tailored respectively for 3D embellishments in doming resin and flat surface protection in coating resin.

Common Applications of Doming Resin

Doming resin is commonly used for creating protective, high-gloss domes on badges, jewelry, and decals, enhancing durability and visual appeal. Its self-leveling properties make it ideal for small-scale applications such as crafts, buttons, and keychains where a raised, clear finish is desired. Unlike coating resin, which is typically applied in thin, flat layers for surface protection, doming resin is formulated to hold shape and depth, providing a three-dimensional effect.

Typical Uses for Coating Resin

Coating resin is typically used for protecting surfaces such as wood, metal, and concrete by forming a durable, glossy layer that resists moisture, UV rays, and scratches. It is ideal for applications requiring a hard, smooth finish like tabletops, floors, and automotive parts. Unlike doming resin, which is primarily used for creating raised, three-dimensional decorative elements, coating resin emphasizes surface protection and enhancement.

Physical Properties Comparison: Doming vs Coating Resin

Doming resin features high viscosity and excellent self-leveling properties, creating a thick, dome-shaped protective layer ideal for small-scale applications like jewelry and badges. Coating resin has lower viscosity, allowing it to spread thinly and evenly over larger surfaces such as tabletops and artwork, providing a smooth, durable finish with superior UV resistance. Both resins cure to a hard, glossy surface but doming resin typically exhibits greater thickness tolerance, while coating resin offers better flow for seamless coverage.

Curing Time and Process: Doming Resin vs Coating Resin

Doming resin typically cures faster, often within 24 hours, due to its thicker application designed to create a raised, dome-like surface, while coating resin cures more slowly, usually requiring 48 to 72 hours, as it forms a thinner, even layer over larger surfaces. The doming resin curing process demands careful control of temperature and humidity to avoid bubbles, whereas coating resin requires gradual curing to achieve a smooth, glossy finish without imperfections. Choosing between the two depends on the project needs for curing speed and surface thickness.

Durability and Longevity: Which Resin Performs Better?

Doming resin generally offers superior durability and longevity compared to coating resin due to its thicker application and enhanced resistance to wear, impacts, and UV exposure. This makes doming resin ideal for protective layers on items subjected to frequent handling or outdoor conditions. Coating resin, while effective for smooth, thin finishes, typically lacks the robust hardness and long-term stability found in doming applications.

Visual Effects: Gloss, Clarity, and Finish

Doming resin creates a thick, domed surface that enhances gloss and depth, producing a high-clarity, crystal-like finish ideal for detailed graphics or jewelry. Coating resin forms a thinner, evenly spread layer that provides a smooth, glossy surface with excellent clarity but less pronounced dimensional effects. The choice between them depends on the desired visual impact: doming resin emphasizes a raised, three-dimensional gloss, while coating resin highlights a sleek, flat shine with clear definition.

Choosing the Right Resin for Your Project

Doming resin offers a thick, glossy finish ideal for small, detailed projects like jewelry or badges, enhancing depth and durability. Coating resin is thinner and designed for larger surfaces, providing a smooth, even layer that resists yellowing and scratches. Selecting the right resin depends on project scale, desired finish, and exposure conditions to ensure lasting protection and aesthetic appeal.

Cost Considerations: Doming Resin vs Coating Resin

Doming resin typically incurs higher costs due to its thicker application and specialized curing processes, compared to coating resin which requires less material and simpler techniques. The expense of doming resin is influenced by its ability to create a durable, raised surface ideal for embellishment, while coating resin offers a more economical option for flat, protective layers. Budget decisions should account for these differences, balancing resin performance with project scale and desired aesthetic effects.

Doming Resin vs Coating Resin Infographic

materialdif.com

materialdif.com