Resin PET exhibits two primary structural forms: crystallized and amorphous, each influencing its properties and applications. Crystallization in PET enhances rigidity, thermal resistance, and chemical stability, making it ideal for containers requiring strength and durability. The amorphous form offers greater clarity and flexibility, suitable for packaging that demands transparency and impact resistance.

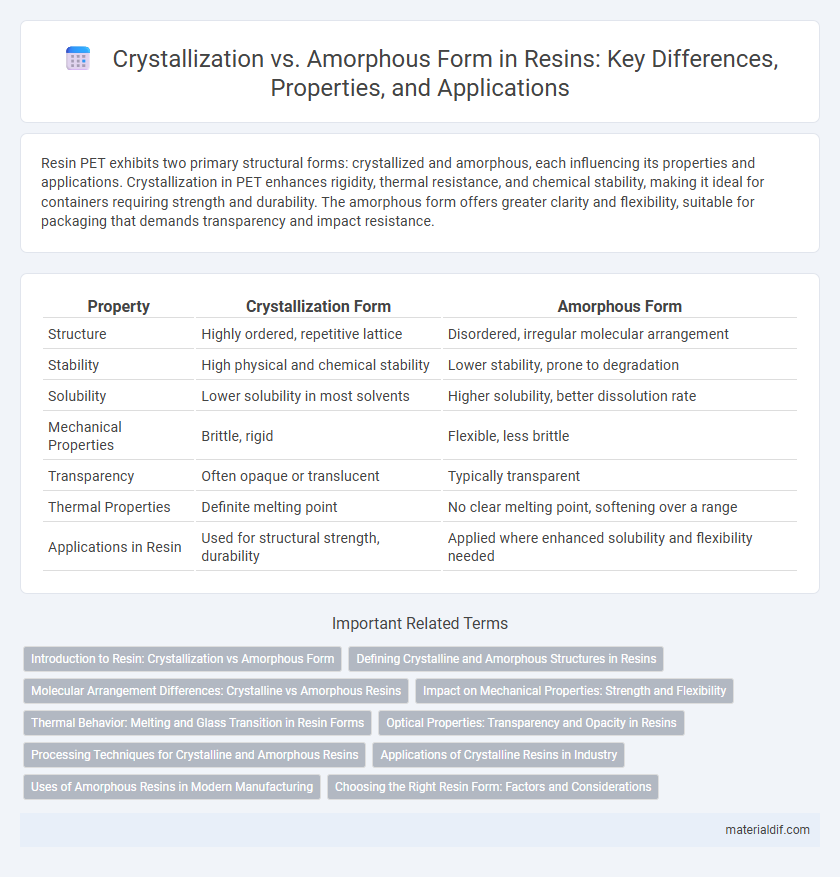

Table of Comparison

| Property | Crystallization Form | Amorphous Form |

|---|---|---|

| Structure | Highly ordered, repetitive lattice | Disordered, irregular molecular arrangement |

| Stability | High physical and chemical stability | Lower stability, prone to degradation |

| Solubility | Lower solubility in most solvents | Higher solubility, better dissolution rate |

| Mechanical Properties | Brittle, rigid | Flexible, less brittle |

| Transparency | Often opaque or translucent | Typically transparent |

| Thermal Properties | Definite melting point | No clear melting point, softening over a range |

| Applications in Resin | Used for structural strength, durability | Applied where enhanced solubility and flexibility needed |

Introduction to Resin: Crystallization vs Amorphous Form

Resins exhibit distinct physical properties based on their molecular arrangement, with crystallization forming an ordered, rigid structure, while the amorphous form remains disordered and more flexible. Crystalline resins typically show higher density, melting points, and mechanical strength, making them suitable for applications requiring durability. In contrast, amorphous resins offer better optical clarity, impact resistance, and processability, favored in coatings and adhesives.

Defining Crystalline and Amorphous Structures in Resins

Crystalline resins exhibit a highly ordered molecular structure where polymer chains arrange in regular, repeating patterns, enhancing rigidity and chemical resistance. Amorphous resins lack this order, featuring randomly coiled polymer chains that provide greater transparency and impact resistance but lower melting points. Understanding the distinct molecular organization in crystalline versus amorphous resins is essential for tailoring material properties for applications like coatings, adhesives, and molded products.

Molecular Arrangement Differences: Crystalline vs Amorphous Resins

Crystalline resins exhibit a highly ordered molecular arrangement, where polymer chains align in a repeating, structured lattice that enhances density, melting point, and mechanical strength. In contrast, amorphous resins feature disordered, irregular polymer chains with random spatial distribution, resulting in lower density, glass transition temperature, and improved optical clarity. This molecular organization difference significantly influences thermal behavior, chemical resistance, and processing characteristics of resins in industrial applications.

Impact on Mechanical Properties: Strength and Flexibility

Crystallization in resin leads to a highly ordered molecular structure, which significantly enhances strength and rigidity but reduces flexibility. In contrast, amorphous resin exhibits a disordered molecular arrangement, providing greater flexibility and impact resistance at the cost of lower tensile strength. The balance between crystalline and amorphous phases directly influences the performance characteristics, making crystallinity a critical factor in resin selection for mechanical applications.

Thermal Behavior: Melting and Glass Transition in Resin Forms

Crystallization in resin results in a distinct melting point characterized by sharp endothermic peaks during thermal analysis, indicating a well-ordered molecular structure. In contrast, amorphous resin exhibits a glass transition temperature (Tg) rather than a melting point, reflecting its disordered molecular arrangement and gradual softening behavior. The thermal behavior differences between crystalline and amorphous resin forms critically affect processing conditions, mechanical properties, and thermal stability in applications.

Optical Properties: Transparency and Opacity in Resins

Crystallization in resins increases opacity due to light scattering from crystalline regions, reducing transparency and causing a frosted or cloudy appearance. Amorphous resins maintain a uniform molecular structure, allowing for higher transparency and better light transmission. Optical clarity in applications such as coatings and optical devices depends significantly on controlling resin crystallinity to balance mechanical and visual properties.

Processing Techniques for Crystalline and Amorphous Resins

Crystalline resins require controlled cooling and annealing processes to promote orderly molecular alignment, enhancing mechanical strength and thermal resistance. Amorphous resins benefit from rapid quenching and careful extrusion to prevent crystallization, maintaining transparency and flexibility. Processing parameters such as temperature profiles and cooling rates are critical to optimizing resin properties based on their crystalline or amorphous nature.

Applications of Crystalline Resins in Industry

Crystalline resins exhibit well-ordered molecular structures that provide superior mechanical strength, thermal stability, and chemical resistance, making them ideal for applications in automotive parts, electrical components, and packaging materials. Their ability to maintain dimensional stability under stress enhances performance in precision engineering and high-temperature environments. In contrast to amorphous resins, crystalline variants offer improved barrier properties, critical for food packaging and medical device manufacturing.

Uses of Amorphous Resins in Modern Manufacturing

Amorphous resins play a crucial role in modern manufacturing due to their unique molecular structure, which provides excellent clarity, toughness, and impact resistance compared to crystalline forms. These resins are widely used in applications such as optical lenses, electronic components, and high-performance adhesives, benefiting from their uniformity and ability to absorb stress without cracking. Their ease of processing and enhanced mechanical properties make amorphous resins indispensable in industries demanding precision and durability.

Choosing the Right Resin Form: Factors and Considerations

Choosing the right resin form depends on the desired mechanical properties, clarity, and thermal stability, with crystalline resins offering higher strength and chemical resistance, while amorphous resins provide better transparency and dimensional stability. Factors such as processing temperature, application environment, and end-use requirements dictate whether the crystallization rate and degree of crystallinity or the isotropic nature of the amorphous phase are more advantageous. Understanding these material characteristics ensures optimal performance in applications ranging from automotive components to optical devices.

Crystallization vs Amorphous Form Infographic

materialdif.com

materialdif.com