Marine resin is specially formulated to withstand harsh marine environments, offering superior resistance to saltwater, UV rays, and extreme weather conditions, making it ideal for boat repairs and coastal applications. Craft resin, on the other hand, prioritizes clarity and ease of use, perfect for creating art, jewelry, and decorative objects with a smooth finish and vibrant colors. While craft resin is designed for indoor projects and aesthetic purposes, marine resin is engineered for durability and long-term performance in demanding outdoor settings.

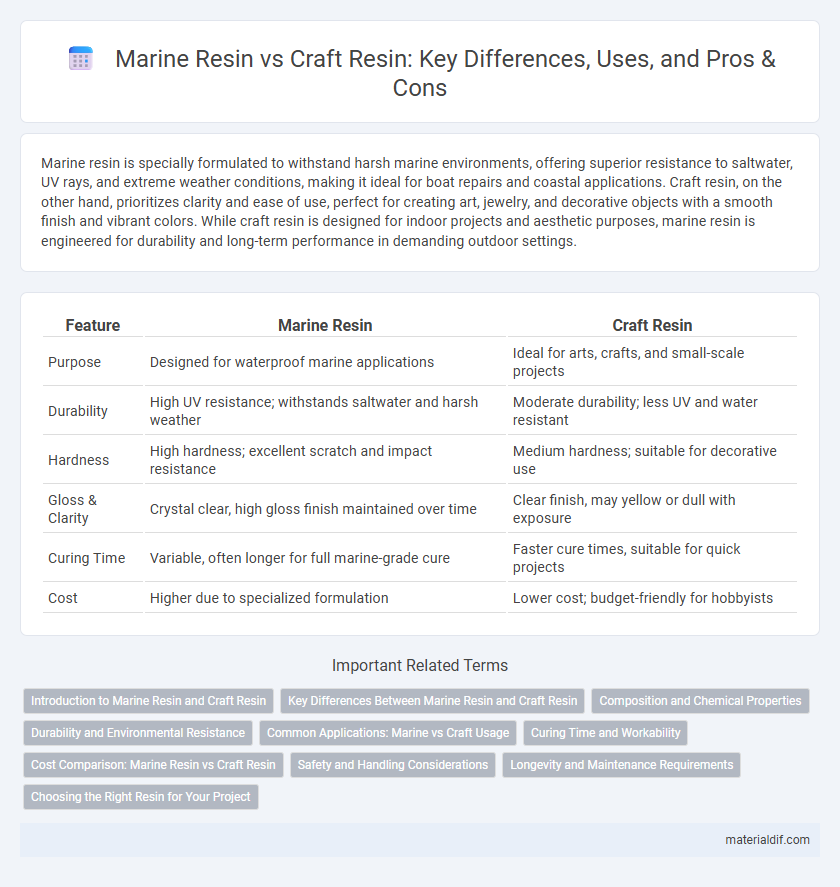

Table of Comparison

| Feature | Marine Resin | Craft Resin |

|---|---|---|

| Purpose | Designed for waterproof marine applications | Ideal for arts, crafts, and small-scale projects |

| Durability | High UV resistance; withstands saltwater and harsh weather | Moderate durability; less UV and water resistant |

| Hardness | High hardness; excellent scratch and impact resistance | Medium hardness; suitable for decorative use |

| Gloss & Clarity | Crystal clear, high gloss finish maintained over time | Clear finish, may yellow or dull with exposure |

| Curing Time | Variable, often longer for full marine-grade cure | Faster cure times, suitable for quick projects |

| Cost | Higher due to specialized formulation | Lower cost; budget-friendly for hobbyists |

Introduction to Marine Resin and Craft Resin

Marine resin is a high-performance epoxy resin specifically formulated for superior water resistance, UV stability, and durability, making it ideal for boat building, repairs, and marine environments. Craft resin, also known as art resin, is designed for ease of use, clarity, and a high-gloss finish, commonly utilized in jewelry making, coatings, and decorative projects. While marine resin prioritizes structural integrity and long-term exposure to harsh conditions, craft resin emphasizes aesthetics and user-friendly application.

Key Differences Between Marine Resin and Craft Resin

Marine resin is specifically formulated for high durability and resistance to water, UV rays, and harsh marine environments, making it ideal for boat repairs and outdoor applications. Craft resin, meanwhile, emphasizes clarity, ease of use, and aesthetic finishes, catering primarily to artistic projects such as jewelry, molds, and decorative items. The key differences lie in marine resin's enhanced protective properties versus craft resin's focus on visual appeal and workability.

Composition and Chemical Properties

Marine resin typically contains UV inhibitors and anti-fouling agents to enhance durability and resistance to water, salt, and sun exposure, making it ideal for harsh marine environments. Craft resin is usually polyester or epoxy-based, formulated for clarity, ease of use, and rapid curing but lacks the specialized additives found in marine resin. Chemical properties of marine resin emphasize long-term stability and flexibility to withstand weathering, whereas craft resin focuses on aesthetic finish and quick hardening for artistic applications.

Durability and Environmental Resistance

Marine resin exhibits superior durability and environmental resistance compared to craft resin, making it ideal for harsh marine conditions. Its formulation includes UV inhibitors and anti-corrosive agents that prevent yellowing, cracking, and degradation caused by prolonged exposure to saltwater, sunlight, and moisture. Craft resin, while suitable for indoor projects, lacks these specialized additives, resulting in lower resistance to weathering and reduced lifespan in outdoor or marine environments.

Common Applications: Marine vs Craft Usage

Marine resin is specifically formulated for high durability and water resistance, making it ideal for boat repairs, hull coatings, and marine equipment protection. Craft resin, designed for aesthetic appeal and ease of use, is commonly used in jewelry making, art projects, and decorative items. Both types offer unique properties tailored to their applications, with marine resin prioritizing strength and longevity in wet environments, while craft resin emphasizes clarity and workability.

Curing Time and Workability

Marine resin typically features longer curing times, often ranging from 24 to 72 hours depending on environmental conditions, ensuring stronger chemical resistance and durability essential for water exposure. Craft resin cures faster, usually within 12 to 24 hours, offering greater workability and ease for detailed projects but with less resistance to moisture. Both resins require careful temperature and humidity control to optimize curing and final mechanical properties.

Cost Comparison: Marine Resin vs Craft Resin

Marine resin typically costs more than craft resin due to its specialized formulation designed to withstand harsh marine environments, including saltwater, UV exposure, and extreme temperatures. Craft resin is generally less expensive, as it is primarily intended for decorative and small-scale projects without the need for high durability or resistance to environmental factors. The price difference justifies marine resin's superior strength and longevity, making it a cost-effective choice for boat repair and outdoor marine applications despite the higher initial investment.

Safety and Handling Considerations

Marine resin typically contains higher levels of volatile organic compounds (VOCs) and styrene, requiring use in well-ventilated areas and with protective equipment such as gloves and respirators to avoid respiratory and skin irritation. Craft resin is generally formulated to be low-odor and non-toxic, making it safer for indoor use and easier to handle without specialized safety gear. Proper storage of both types involves keeping them in cool, dry places away from direct sunlight to prevent premature curing and maintain effective shelf life.

Longevity and Maintenance Requirements

Marine resin is engineered for exceptional durability and resistance to harsh environmental factors like UV rays, saltwater, and moisture, ensuring superior longevity even in extreme marine conditions. Craft resin, while versatile and suitable for indoor applications, typically lacks UV stability and may yellow or degrade faster when exposed to prolonged sunlight or moisture. Maintenance of marine resin involves minimal effort due to its toughness and weather resistance, whereas craft resin may require frequent cleaning and sealing to maintain its appearance and structural integrity over time.

Choosing the Right Resin for Your Project

Marine resin offers superior durability, UV resistance, and water-tightness, making it ideal for outdoor applications and projects exposed to harsh marine environments. Craft resin provides excellent clarity, ease of use, and fast curing times, perfect for detailed artwork, jewelry, and indoor crafts. Selecting the right resin depends on your project's exposure to elements and the desired finish, balancing durability with visual appeal.

Marine Resin vs Craft Resin Infographic

materialdif.com

materialdif.com