Water-clear resin offers exceptional transparency and clarity, making it ideal for projects that require a glass-like finish or vivid color encapsulation. Opaque resin provides solid coverage and vibrant color options, often preferred for artistic designs where light transmission is not desired. Choosing between these resins depends on whether clarity or color density is the priority for the final piece.

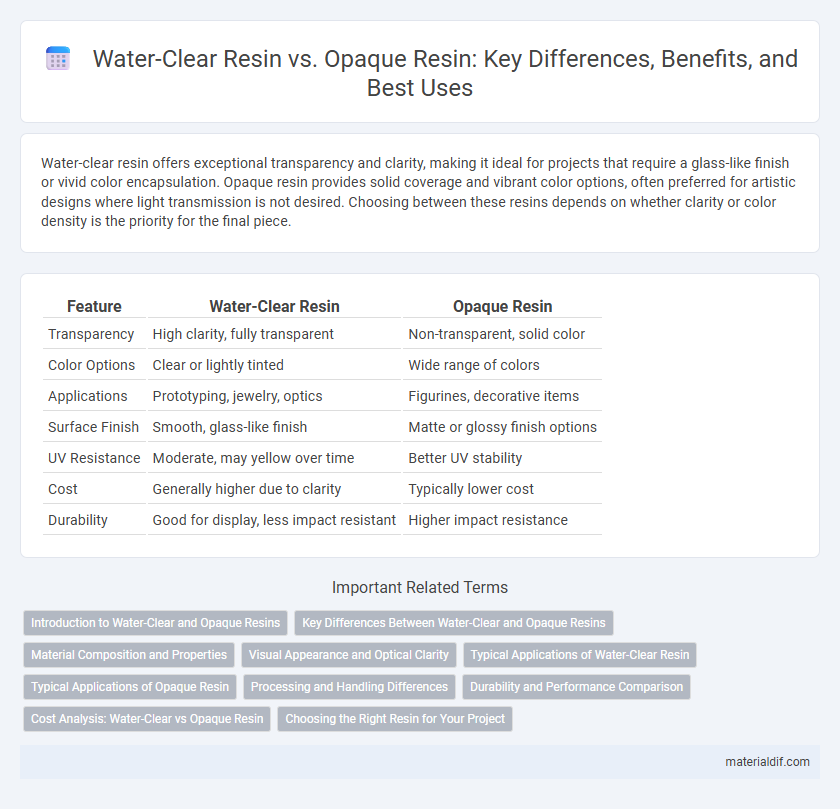

Table of Comparison

| Feature | Water-Clear Resin | Opaque Resin |

|---|---|---|

| Transparency | High clarity, fully transparent | Non-transparent, solid color |

| Color Options | Clear or lightly tinted | Wide range of colors |

| Applications | Prototyping, jewelry, optics | Figurines, decorative items |

| Surface Finish | Smooth, glass-like finish | Matte or glossy finish options |

| UV Resistance | Moderate, may yellow over time | Better UV stability |

| Cost | Generally higher due to clarity | Typically lower cost |

| Durability | Good for display, less impact resistant | Higher impact resistance |

Introduction to Water-Clear and Opaque Resins

Water-clear resin offers exceptional transparency ideal for applications requiring glass-like clarity, such as jewelry, coatings, and artistic projects. Opaque resin provides solid, non-transparent finishes that are preferred in applications needing vibrant color or complete light blockage, like sculpting and manufacturing durable parts. Understanding the difference between these resin types helps optimize material selection based on visual and functional requirements.

Key Differences Between Water-Clear and Opaque Resins

Water-clear resin offers exceptional transparency and clarity, making it ideal for projects that require glass-like finishes and detailed visual effects. Opaque resin provides solid color saturation and hides imperfections, perfect for applications needing bold, consistent hues or less light penetration. The choice hinges on the desired translucency, with water-clear resin suited for aesthetic depth and opaque resin preferred for vibrant, uniform coverage.

Material Composition and Properties

Water-clear resin is typically formulated from high-purity epoxy or polyurethane monomers, offering exceptional transparency and light transmission, making it ideal for applications requiring optical clarity. Opaque resin often incorporates additives such as titanium dioxide or other pigments that enhance durability, UV resistance, and mechanical strength but reduce translucency. The choice between water-clear and opaque resin depends on balancing the need for visual clarity against physical performance characteristics like hardness and resistance to environmental factors.

Visual Appearance and Optical Clarity

Water-clear resin offers exceptional optical clarity with a transparent, glass-like appearance that enhances color vibrancy and reveals intricate details beneath the surface. Opaque resin, by contrast, features a solid, non-transparent finish that conceals internal components, providing a matte or glossy look without light penetration. The choice between water-clear and opaque resin significantly affects the visual impact and texture perception of finished projects.

Typical Applications of Water-Clear Resin

Water-clear resin is primarily used in applications requiring high transparency and optical clarity, such as in lenses, protective coatings, and clear casting for art and jewelry. It excels in automotive and electronic device components where unobstructed visibility is crucial. Its ability to mimic glass makes it ideal for decorative objects, displays, and prototypes demanding a flawless, see-through finish.

Typical Applications of Opaque Resin

Opaque resin is commonly used in applications requiring color stability and light blockage, such as automotive parts, household appliances, and electronic housings. Its ability to mask underlying surfaces makes it ideal for decorative items, packaging, and medical devices where appearance and functionality are critical. Industrial components and toys frequently utilize opaque resin due to its durability and variety of available colors.

Processing and Handling Differences

Water-clear resin offers superior transparency, making it ideal for projects requiring visual clarity, but it demands more precise curing times and controlled temperatures to prevent yellowing and maintain its clarity. Opaque resin, on the other hand, is more forgiving with processing conditions, allowing for faster curing and less sensitivity to light exposure, which simplifies handling. While water-clear resin requires careful mixing to avoid bubbles, opaque resin's pigments help mask minor imperfections, reducing the need for extensive surface finishing.

Durability and Performance Comparison

Water-clear resin offers superior optical clarity and UV resistance, making it ideal for applications requiring transparency and durability against discoloration over time. Opaque resin typically provides enhanced impact resistance and chemical durability, suited for structural parts exposed to harsh conditions. Both resins exhibit high mechanical strength, but water-clear resin prioritizes aesthetic performance while opaque resin focuses on toughness and longevity in demanding environments.

Cost Analysis: Water-Clear vs Opaque Resin

Water-clear resin generally costs more per gallon due to higher purity and refined processing requirements compared to opaque resin, which contains additives that reduce manufacturing expenses. While water-clear resin offers superior optical clarity and is preferred for aesthetic and decorative applications, opaque resin is favored for cost-sensitive projects where transparency is not critical. Evaluating total project expenses must consider the resin type's impact on material cost, processing time, and final product quality to determine the most economical choice.

Choosing the Right Resin for Your Project

Water-clear resin offers exceptional transparency ideal for projects requiring glass-like clarity, such as jewelry or decorative objects where light transmission and visual depth are essential. Opaque resin provides consistent, solid color without translucency, making it perfect for items needing bold hues, hiding embedded imperfections, or enhancing durability with pigments. Selecting the right resin depends on the desired visual effect, project function, and how light interacts with the final product's surface and internal elements.

Water-Clear Resin vs Opaque Resin Infographic

materialdif.com

materialdif.com