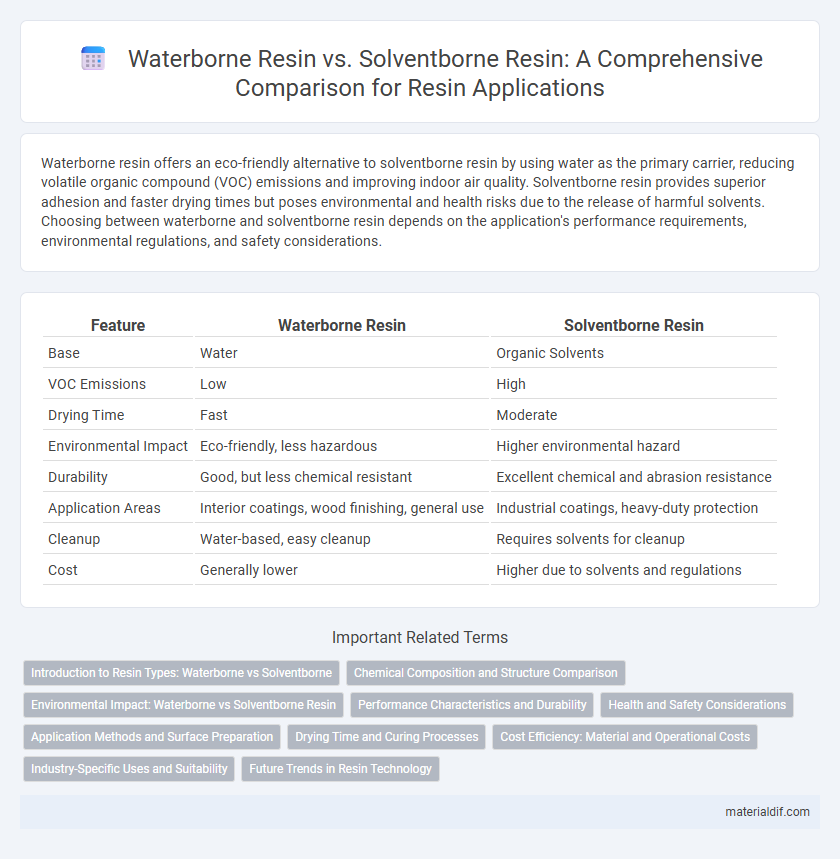

Waterborne resin offers an eco-friendly alternative to solventborne resin by using water as the primary carrier, reducing volatile organic compound (VOC) emissions and improving indoor air quality. Solventborne resin provides superior adhesion and faster drying times but poses environmental and health risks due to the release of harmful solvents. Choosing between waterborne and solventborne resin depends on the application's performance requirements, environmental regulations, and safety considerations.

Table of Comparison

| Feature | Waterborne Resin | Solventborne Resin |

|---|---|---|

| Base | Water | Organic Solvents |

| VOC Emissions | Low | High |

| Drying Time | Fast | Moderate |

| Environmental Impact | Eco-friendly, less hazardous | Higher environmental hazard |

| Durability | Good, but less chemical resistant | Excellent chemical and abrasion resistance |

| Application Areas | Interior coatings, wood finishing, general use | Industrial coatings, heavy-duty protection |

| Cleanup | Water-based, easy cleanup | Requires solvents for cleanup |

| Cost | Generally lower | Higher due to solvents and regulations |

Introduction to Resin Types: Waterborne vs Solventborne

Waterborne resin utilizes water as a primary carrier, offering low VOC emissions and enhanced environmental safety, making it ideal for eco-friendly coatings and adhesives. Solventborne resin relies on organic solvents, providing superior film formation and durability but often involves higher VOC levels. Choosing between waterborne and solventborne resins depends on application requirements, regulatory compliance, and performance characteristics.

Chemical Composition and Structure Comparison

Waterborne resins consist primarily of polymer particles dispersed in water, featuring hydrophilic groups that enhance their compatibility with aqueous systems, whereas solventborne resins are composed of polymers dissolved in organic solvents, containing hydrophobic molecular structures promoting solubility in nonpolar media. Chemically, waterborne resins often have ionic or nonionic surfactant groups incorporated to stabilize emulsions, while solventborne resins rely on lower polarity functional groups that ensure solubility and film formation in solvent-based environments. Structurally, waterborne resins exhibit a core-shell morphology to balance hydrophobic polymer cores with hydrophilic shells, contrasting with the homogeneous structure of solventborne resins characterized by uniformly hydrophobic polymer chains.

Environmental Impact: Waterborne vs Solventborne Resin

Waterborne resins significantly reduce volatile organic compound (VOC) emissions compared to solventborne resins, minimizing air pollution and health risks. The lower solvent content in waterborne resins leads to reduced hazardous waste and easier regulatory compliance. This environmentally friendly profile makes waterborne resins a preferred choice for sustainable coatings and adhesive applications.

Performance Characteristics and Durability

Waterborne resins exhibit superior environmental compliance and lower VOC emissions while offering excellent flexibility and adhesion, making them ideal for applications requiring eco-friendly solutions. Solventborne resins typically provide enhanced chemical resistance, faster curing times, and greater hardness, resulting in higher durability for demanding industrial environments. Both resin types have unique performance characteristics where waterborne resins excel in sustainability and ease of application, whereas solventborne resins outperform in long-term abrasion and solvent resistance.

Health and Safety Considerations

Waterborne resins significantly reduce volatile organic compound (VOC) emissions, minimizing respiratory hazards and environmental impact compared to solventborne resins, which release higher levels of toxic fumes. The lower flammability of waterborne resins enhances workplace safety by reducing fire risks associated with solventborne alternatives. Proper ventilation and personal protective equipment remain essential when handling both types, but waterborne resins offer a safer profile for long-term health exposure.

Application Methods and Surface Preparation

Waterborne resins require thorough surface cleaning to ensure optimal adhesion, often applied using spray, brush, or roller techniques that promote even drying and minimize VOC emissions. Solventborne resins demand meticulous surface preparation, including degreasing and abrasion, to enhance bonding, with application methods primarily focused on spraying and brushing for smooth, durable coatings. Both resin types benefit from controlled environmental conditions during application to prevent defects such as bubbling and poor film formation.

Drying Time and Curing Processes

Waterborne resins typically offer faster drying times due to the rapid evaporation of water, allowing coatings to become tack-free more quickly compared to solventborne resins, which rely on slower solvent evaporation. The curing process of waterborne resins often involves coalescence and film formation facilitated by water removal, while solventborne resins cure through solvent evaporation combined with chemical cross-linking, resulting in a harder, more durable finish. Understanding these differences is essential for optimizing application conditions and final coating performance in industries such as automotive, woodworking, and industrial coatings.

Cost Efficiency: Material and Operational Costs

Waterborne resins generally offer lower material costs due to reduced solvent content and simpler regulatory compliance requirements, which lead to decreased expenses for hazardous waste disposal and air quality permits. Operational costs are also minimized with waterborne resins as they require less specialized ventilation and lower energy consumption during drying processes compared to solventborne resins. In contrast, solventborne resins entail higher costs from solvent procurement, increased safety measures, and complex environmental controls, impacting overall cost efficiency in industrial applications.

Industry-Specific Uses and Suitability

Waterborne resin is preferred in industries such as automotive, furniture, and packaging for its low VOC emissions and environmental compliance, making it suitable for indoor applications requiring fast drying and minimal odor. Solventborne resin excels in industrial coatings, marine, and heavy machinery sectors due to its superior adhesion, chemical resistance, and durability under harsh conditions. Each resin type's suitability depends on factors like substrate compatibility, regulatory requirements, and performance needs in the specific industry.

Future Trends in Resin Technology

Waterborne resin technology is rapidly advancing due to increasing environmental regulations and growing demand for low-VOC coatings, driving innovation in bio-based and high-performance formulations. Solventborne resins continue to evolve with enhanced durability and chemical resistance, but face challenges from stricter emission standards and a global shift toward sustainable practices. Future trends emphasize hybrid resin systems combining waterborne and solventborne benefits, along with nanotechnology integration to improve mechanical properties and application efficiency.

Waterborne Resin vs Solventborne Resin Infographic

materialdif.com

materialdif.com