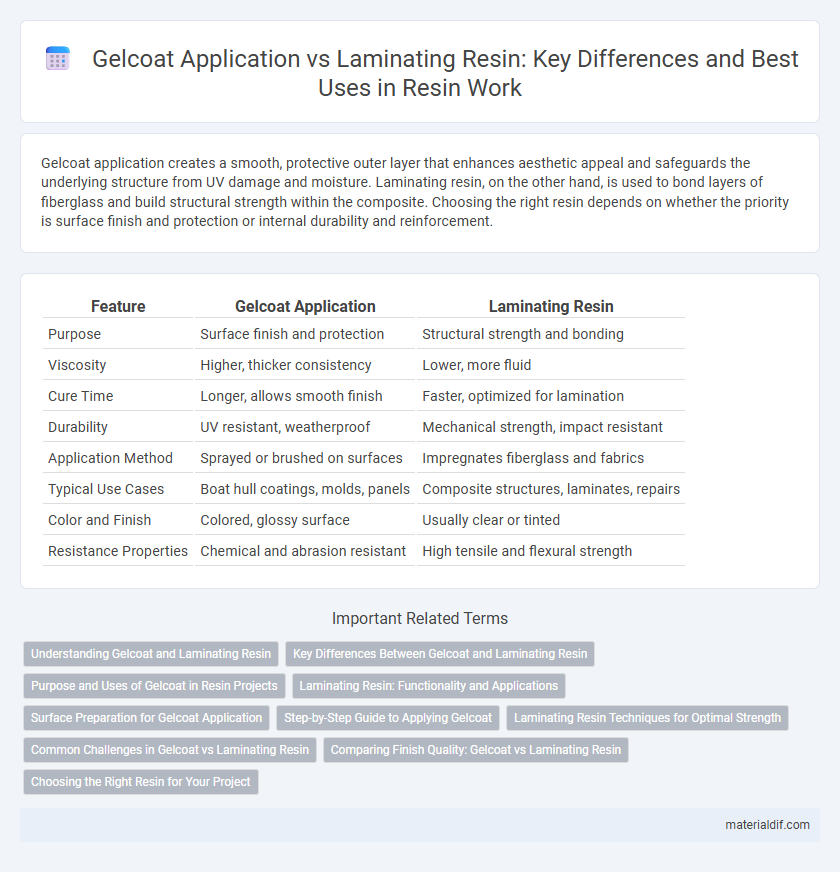

Gelcoat application creates a smooth, protective outer layer that enhances aesthetic appeal and safeguards the underlying structure from UV damage and moisture. Laminating resin, on the other hand, is used to bond layers of fiberglass and build structural strength within the composite. Choosing the right resin depends on whether the priority is surface finish and protection or internal durability and reinforcement.

Table of Comparison

| Feature | Gelcoat Application | Laminating Resin |

|---|---|---|

| Purpose | Surface finish and protection | Structural strength and bonding |

| Viscosity | Higher, thicker consistency | Lower, more fluid |

| Cure Time | Longer, allows smooth finish | Faster, optimized for lamination |

| Durability | UV resistant, weatherproof | Mechanical strength, impact resistant |

| Application Method | Sprayed or brushed on surfaces | Impregnates fiberglass and fabrics |

| Typical Use Cases | Boat hull coatings, molds, panels | Composite structures, laminates, repairs |

| Color and Finish | Colored, glossy surface | Usually clear or tinted |

| Resistance Properties | Chemical and abrasion resistant | High tensile and flexural strength |

Understanding Gelcoat and Laminating Resin

Gelcoat is a highly durable, pigmented resin applied as a protective outer layer to enhance the surface finish and UV resistance of fiberglass products. Laminating resin, commonly polyester or epoxy, provides structural strength by bonding the fiberglass layers and forming the composite's core material. Understanding the distinct roles allows optimal use of gelcoat for aesthetics and surface protection, while laminating resin ensures mechanical integrity and load-bearing capacity.

Key Differences Between Gelcoat and Laminating Resin

Gelcoat is a pigmented resin used as a protective outer layer on composites, providing UV resistance, a smooth finish, and durability, while laminating resin serves as a structural bonding agent that impregnates reinforcing fibers for strength and rigidity. Gelcoat typically cures to a hard, glossy surface ideal for aesthetics and environmental protection, whereas laminating resin is formulated for optimal wet-out and adhesion to fiberglass or carbon fibers during composite layup. The chemical composition differs as gelcoat contains fillers and colorants for surface quality, whereas laminating resin emphasizes mechanical properties and compatibility with reinforcement materials.

Purpose and Uses of Gelcoat in Resin Projects

Gelcoat serves as a protective outer layer in resin projects, providing a smooth, durable, and aesthetically pleasing finish that resists UV damage, moisture, and chemical exposure. It is primarily used in marine, automotive, and architectural applications to enhance surface appearance and improve longevity. Unlike laminating resin, which is designed for structural bonding and reinforcement, gelcoat focuses on surface protection and visual appeal.

Laminating Resin: Functionality and Applications

Laminating resin serves as the primary bonding agent in composite manufacturing, providing structural strength and durability when combined with reinforcement materials like fiberglass or carbon fiber. Its high adhesion properties and excellent mechanical performance make it essential for constructing marine hulls, automotive parts, and sporting equipment. Unlike gelcoat, which offers surface protection and aesthetic finish, laminating resin ensures the integrity and load-bearing capability of the final composite product.

Surface Preparation for Gelcoat Application

Proper surface preparation is critical for gelcoat application to ensure optimal adhesion and a smooth finish. The substrate must be clean, dry, and free of contaminants such as dust, oils, or grease, often achieved by sanding with fine-grit abrasive followed by solvent wiping. Unlike laminating resin, which bonds layers of fiberglass, gelcoat requires a meticulously prepared surface to prevent defects like blistering or delamination.

Step-by-Step Guide to Applying Gelcoat

Applying gelcoat requires a clean, dry surface, followed by thorough sanding to ensure proper adhesion; mix the gelcoat with the appropriate catalyst as per manufacturer guidelines. Use a dedicated gelcoat brush or roller to apply a smooth, even coat, working in thin layers to avoid drips and ensure uniform coverage. Allow the gelcoat to partially cure before sanding lightly and applying subsequent layers or laminating resin for optimal finish and durability.

Laminating Resin Techniques for Optimal Strength

Laminating resin techniques prioritize the application of multiple thin layers of resin combined with reinforcing fibers like fiberglass to maximize structural integrity and strength. Precise mixing ratios and thorough saturation are critical to avoid air bubbles and ensure uniform adhesion throughout the laminate. Controlled curing environments and proper resin-to-fiber ratios enhance the mechanical properties, resulting in durable, high-strength composite structures.

Common Challenges in Gelcoat vs Laminating Resin

Gelcoat application often faces challenges such as achieving a smooth, bubble-free surface and ensuring proper curing without surface defects like orange peel or blushing. Laminating resin, on the other hand, requires precise resin-to-fiber ratios to prevent issues like delamination, voids, or inadequate adhesive bonding. Both gelcoat and laminating resin demand stringent environmental control, including temperature and humidity, to optimize curing and final part durability.

Comparing Finish Quality: Gelcoat vs Laminating Resin

Gelcoat provides a smooth, high-gloss finish that enhances UV resistance and surface durability, making it ideal for visible surfaces requiring aesthetic appeal. Laminating resin, while strong and structural, typically results in a less polished finish that may require additional surface treatment to achieve a smooth appearance. The choice between gelcoat and laminating resin largely depends on the desired balance between surface quality and mechanical strength in composite applications.

Choosing the Right Resin for Your Project

Gelcoat application provides a smooth, durable surface finish that protects underlying laminates from UV damage and moisture, making it essential for exterior marine and automotive projects. Laminating resin, such as polyester or epoxy, offers high strength and structural integrity by bonding reinforcement fibers and building the composite's core. Selecting the right resin depends on project requirements for surface finish, mechanical strength, environmental resistance, and compatibility with reinforcements.

Gelcoat Application vs Laminating Resin Infographic

materialdif.com

materialdif.com