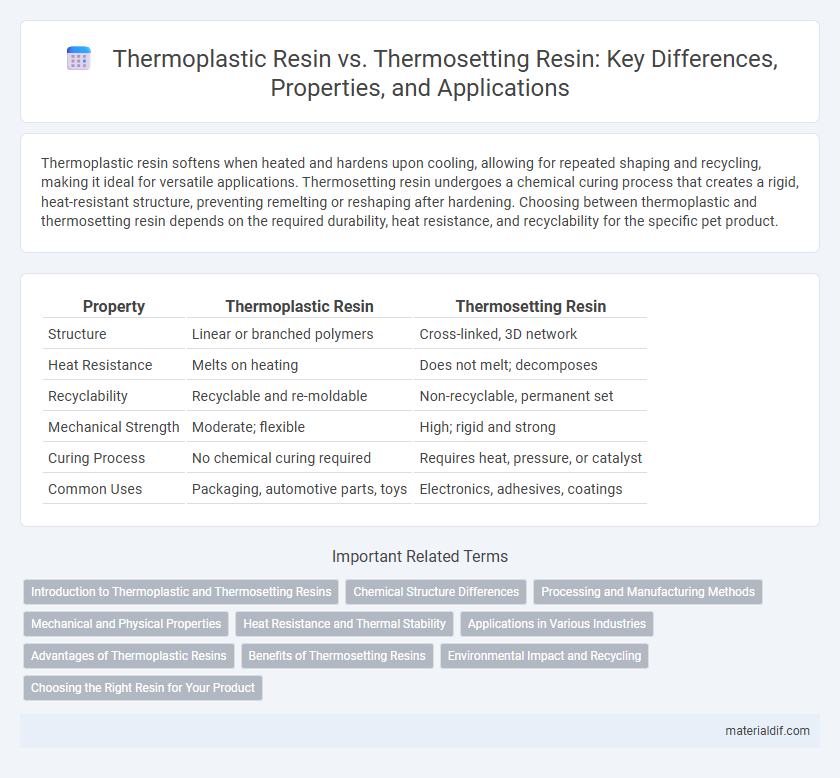

Thermoplastic resin softens when heated and hardens upon cooling, allowing for repeated shaping and recycling, making it ideal for versatile applications. Thermosetting resin undergoes a chemical curing process that creates a rigid, heat-resistant structure, preventing remelting or reshaping after hardening. Choosing between thermoplastic and thermosetting resin depends on the required durability, heat resistance, and recyclability for the specific pet product.

Table of Comparison

| Property | Thermoplastic Resin | Thermosetting Resin |

|---|---|---|

| Structure | Linear or branched polymers | Cross-linked, 3D network |

| Heat Resistance | Melts on heating | Does not melt; decomposes |

| Recyclability | Recyclable and re-moldable | Non-recyclable, permanent set |

| Mechanical Strength | Moderate; flexible | High; rigid and strong |

| Curing Process | No chemical curing required | Requires heat, pressure, or catalyst |

| Common Uses | Packaging, automotive parts, toys | Electronics, adhesives, coatings |

Introduction to Thermoplastic and Thermosetting Resins

Thermoplastic resins are polymers that soften when heated and harden upon cooling, enabling repeated reshaping without altering their chemical structure. Thermosetting resins undergo an irreversible curing process, forming a rigid, cross-linked network that cannot be remelted or reshaped after setting. Key examples include polyethylene and polypropylene for thermoplastics, while epoxy and phenolic resins represent common thermosetting types, each offering distinct thermal and mechanical properties suited to various industrial applications.

Chemical Structure Differences

Thermoplastic resins consist of linear or branched polymer chains without cross-linking, allowing them to be melted and reshaped multiple times. Thermosetting resins form highly cross-linked, three-dimensional networks during curing, resulting in rigid structures that cannot be remelted. These chemical structure differences determine their thermal properties, mechanical strength, and recyclability in various applications.

Processing and Manufacturing Methods

Thermoplastic resins undergo melting and solidification repeatedly, allowing processes like injection molding, extrusion, and thermoforming for efficient manufacturing and easy recycling. Thermosetting resins cure irreversibly through heat or chemical reactions, commonly used in compression molding and transfer molding, resulting in a rigid and heat-resistant final product. These distinct processing methods influence production speed, product durability, and recyclability in applications ranging from automotive parts to electronics.

Mechanical and Physical Properties

Thermoplastic resins exhibit excellent impact resistance, flexibility, and the ability to be remelted and reshaped multiple times, making them ideal for applications requiring toughness and recyclability. Thermosetting resins, in contrast, provide superior dimensional stability, high heat resistance, and enhanced mechanical strength due to their cross-linked molecular structure, which prevents remelting after curing. The rigid network of thermosetting resins contributes to higher chemical resistance and hardness, while thermoplastics offer better elongation and ductility under stress.

Heat Resistance and Thermal Stability

Thermosetting resins exhibit superior heat resistance and thermal stability compared to thermoplastic resins due to their cross-linked polymer structure that maintains integrity at elevated temperatures. Thermoplastic resins tend to soften and deform under heat as their molecular chains are not chemically bonded, limiting their application in high-temperature environments. The enhanced thermal stability of thermosetting resins makes them ideal for industrial uses requiring long-term exposure to heat without structural failure.

Applications in Various Industries

Thermoplastic resin finds extensive use in industries such as automotive, packaging, and consumer electronics due to its ability to be repeatedly melted and reshaped, enabling efficient manufacturing and recycling. Thermosetting resin is preferred in aerospace, electrical insulation, and adhesives industries because of its superior heat resistance, mechanical strength, and chemical stability after curing. The distinct thermal and mechanical properties of these resins dictate their specialized applications, driving innovation in product design and durability across diverse sectors.

Advantages of Thermoplastic Resins

Thermoplastic resins offer superior recyclability and reusability due to their ability to be melted and remolded multiple times without significant degradation. These resins exhibit excellent impact resistance and flexibility, making them ideal for applications requiring durability and toughness. Their faster processing times and resistance to chemical corrosion enhance manufacturing efficiency and product longevity.

Benefits of Thermosetting Resins

Thermosetting resins offer superior heat resistance and dimensional stability compared to thermoplastic resins, making them ideal for high-temperature applications. Their cross-linked molecular structure provides excellent mechanical strength, chemical resistance, and electrical insulation properties. These benefits enhance durability and performance in demanding environments such as aerospace, automotive, and electronics industries.

Environmental Impact and Recycling

Thermoplastic resins are more environmentally friendly due to their ability to be repeatedly melted and remolded, facilitating easier recycling and reducing plastic waste. In contrast, thermosetting resins undergo irreversible chemical curing, which makes recycling challenging and often leads to disposal through incineration or landfill. The recyclability of thermoplastic resins contributes significantly to reduced environmental impact and resource conservation in comparison to thermosetting resins.

Choosing the Right Resin for Your Product

Thermoplastic resins, such as polyethylene and polypropylene, offer excellent flexibility and recyclability, making them ideal for products requiring reshaping or repeated use. Thermosetting resins like epoxy and phenolic cure irreversibly, providing superior heat resistance and structural strength, which is crucial for durable, high-performance applications. Selecting the right resin hinges on product requirements, including mechanical strength, thermal stability, and end-of-life recyclability.

Thermoplastic resin vs Thermosetting resin Infographic

materialdif.com

materialdif.com