UV resin cures quickly under ultraviolet light, making it ideal for small crafts and jewelry with detailed designs, while casting resin requires longer curing times but offers superior strength and durability for larger molds. UV resin provides a clear, glossy finish and is easier to work with for intricate projects, whereas casting resin is better suited for creating solid, robust pieces with deep pours. Choosing between UV and casting resin depends on the application's complexity, size, and desired finish quality.

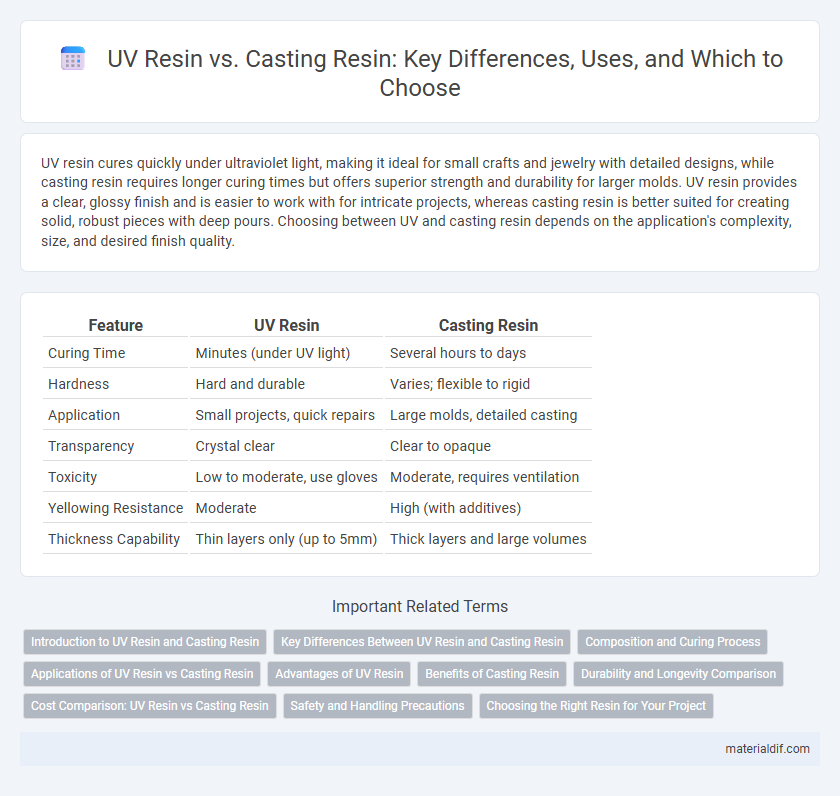

Table of Comparison

| Feature | UV Resin | Casting Resin |

|---|---|---|

| Curing Time | Minutes (under UV light) | Several hours to days |

| Hardness | Hard and durable | Varies; flexible to rigid |

| Application | Small projects, quick repairs | Large molds, detailed casting |

| Transparency | Crystal clear | Clear to opaque |

| Toxicity | Low to moderate, use gloves | Moderate, requires ventilation |

| Yellowing Resistance | Moderate | High (with additives) |

| Thickness Capability | Thin layers only (up to 5mm) | Thick layers and large volumes |

Introduction to UV Resin and Casting Resin

UV resin cures quickly under ultraviolet light, offering a fast and convenient solution for small, detailed projects like jewelry and crafts. Casting resin typically requires mixing two components and cures over several hours, providing durability and clarity for larger molds and industrial applications. Both resins differ in curing processes, working time, and ideal use cases, making selection dependent on project requirements.

Key Differences Between UV Resin and Casting Resin

UV resin cures quickly under ultraviolet light, allowing for rapid project completion and fine detail work, making it ideal for small crafts and jewelry. Casting resin, typically a two-part epoxy or polyester, cures through a chemical reaction and is better suited for larger molds and thicker pours due to its longer curing time and greater durability. Key differences include curing method, working time, strength, and application thickness, with UV resin offering speed and precision while casting resin provides robustness and versatility.

Composition and Curing Process

UV resin is composed of acrylates that cure quickly under ultraviolet light, enabling rapid hardening within minutes and precise control over the curing process. Casting resin consists primarily of epoxy or polyester compounds that undergo a chemical reaction when mixed with a hardener, requiring several hours to fully cure and offering robust mechanical properties. The composition differences dictate their curing methods, with UV resin favoring light exposure for instant curing and casting resin relying on a time-dependent chemical cure.

Applications of UV Resin vs Casting Resin

UV resin is ideal for small, detailed projects such as jewelry, nail art, and miniature models due to its fast curing time under UV light and ability to produce a smooth, glossy finish. Casting resin, often a two-part epoxy or polyester resin, is preferred for larger molds and complex shapes in applications like sculpture, prototyping, and industrial parts because of its longer working time and greater depth curing capability. Both resins are chosen based on project scale and detail, with UV resin excelling in quick, precise applications and casting resin suited for substantial, durable creations.

Advantages of UV Resin

UV resin cures rapidly under ultraviolet light, enabling swift project completion and reducing wait times compared to traditional casting resin that relies on chemical curing. It offers superior control over the curing process, allowing precise layering and intricate detailing without mixing errors or bubbles commonly found in casting resin. The low odor and minimal shrinkage of UV resin enhance user safety and result in more durable, high-gloss finishes ideal for jewelry, coating, and small-scale crafts.

Benefits of Casting Resin

Casting resin offers superior durability and strength, making it ideal for creating robust and long-lasting items such as jewelry, sculptures, and industrial prototypes. Its low viscosity ensures excellent detail reproduction and bubbles are minimal during the curing process, resulting in smooth, clear finishes. Compared to UV resin, casting resin cures uniformly under heat rather than light, enabling thicker pours without the risk of incomplete curing or yellowing over time.

Durability and Longevity Comparison

UV resin cures quickly under ultraviolet light, forming a hard, glossy surface ideal for small projects and detailed finishes, but it tends to be less durable and more prone to yellowing over time compared to casting resin. Casting resin, often based on epoxy or polyester, cures through a chemical reaction that results in a thicker, tougher material with superior impact resistance and long-term stability, making it suitable for larger, functional items. The longevity of casting resin outperforms UV resin in resisting UV degradation, cracking, and wear, ensuring prolonged durability in various environmental conditions.

Cost Comparison: UV Resin vs Casting Resin

UV resin typically costs more per ounce but cures faster under UV light, making it ideal for small projects and quick turnarounds. Casting resin is generally more affordable in bulk and better suited for larger molds, with longer curing times that can impact overall project duration. Comparing cost efficiency depends on project size, curing requirements, and desired finish quality.

Safety and Handling Precautions

UV resin cures quickly under ultraviolet light, offering a safe, low-odor solution but requires protective gloves and eye protection to prevent skin irritation and UV exposure. Casting resin, often epoxy-based, demands careful handling due to longer curing times and the release of volatile organic compounds (VOCs), necessitating well-ventilated workspaces and respiratory protection. Both types benefit from using disposable gloves, respirators, and proper storage to minimize exposure risks and ensure safe crafting environments.

Choosing the Right Resin for Your Project

UV resin cures quickly under ultraviolet light, making it ideal for small, detailed projects like jewelry or nail art where fast hardening is essential. Casting resin, typically a two-part epoxy or polyurethane, offers greater depth and strength, making it suitable for larger molds, art pieces, and functional parts requiring durability. Selecting the right resin depends on project size, curing time, clarity, and mechanical properties to ensure optimal results.

UV Resin vs Casting Resin Infographic

materialdif.com

materialdif.com