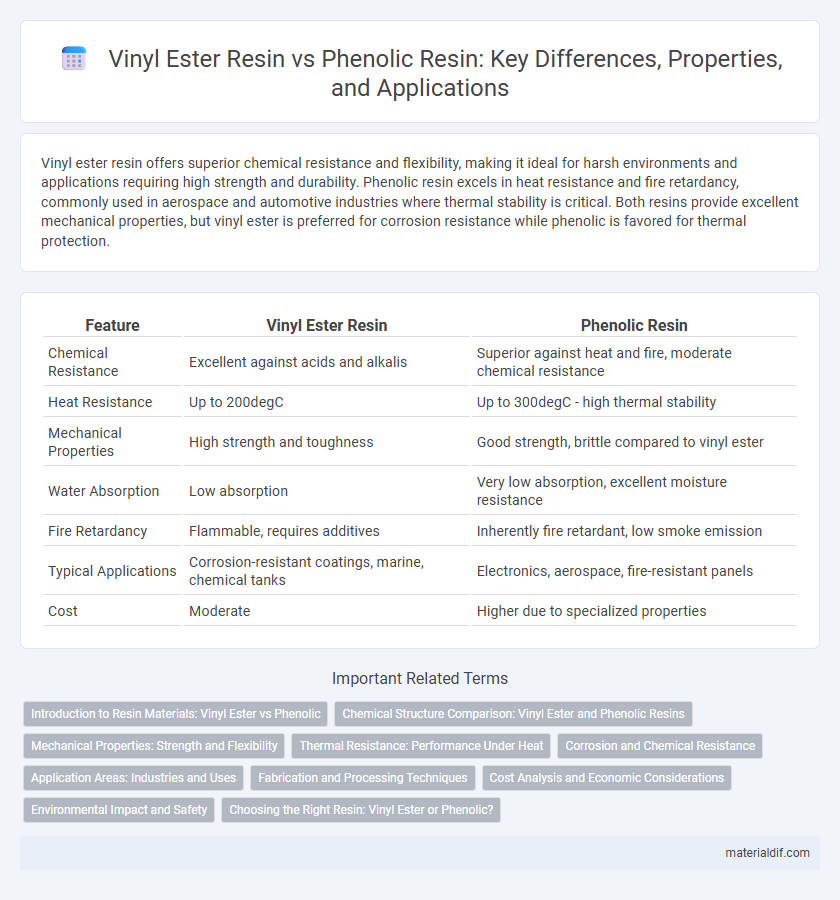

Vinyl ester resin offers superior chemical resistance and flexibility, making it ideal for harsh environments and applications requiring high strength and durability. Phenolic resin excels in heat resistance and fire retardancy, commonly used in aerospace and automotive industries where thermal stability is critical. Both resins provide excellent mechanical properties, but vinyl ester is preferred for corrosion resistance while phenolic is favored for thermal protection.

Table of Comparison

| Feature | Vinyl Ester Resin | Phenolic Resin |

|---|---|---|

| Chemical Resistance | Excellent against acids and alkalis | Superior against heat and fire, moderate chemical resistance |

| Heat Resistance | Up to 200degC | Up to 300degC - high thermal stability |

| Mechanical Properties | High strength and toughness | Good strength, brittle compared to vinyl ester |

| Water Absorption | Low absorption | Very low absorption, excellent moisture resistance |

| Fire Retardancy | Flammable, requires additives | Inherently fire retardant, low smoke emission |

| Typical Applications | Corrosion-resistant coatings, marine, chemical tanks | Electronics, aerospace, fire-resistant panels |

| Cost | Moderate | Higher due to specialized properties |

Introduction to Resin Materials: Vinyl Ester vs Phenolic

Vinyl ester resin offers superior corrosion resistance and mechanical strength, making it ideal for marine and chemical processing applications, while phenolic resin excels in fire resistance and thermal stability, commonly used in aerospace and electronics. Both resins are thermosetting polymers, but vinyl ester combines the toughness of epoxy with the chemical resistance of polyester, whereas phenolic resins are valued for their char formation and low smoke emission. Selection depends on specific performance requirements such as chemical exposure, thermal conditions, and structural demands.

Chemical Structure Comparison: Vinyl Ester and Phenolic Resins

Vinyl ester resin consists of ester groups formed by the reaction of epoxy resin with unsaturated monocarboxylic acids, providing enhanced flexibility and chemical resistance. Phenolic resin features a network of phenol rings interconnected by methylene bridges, resulting in high thermal stability and excellent fire retardant properties. The chemical structure of vinyl ester resins offers better resistance to hydrolysis, while phenolic resins excel in mechanical strength and thermal behavior.

Mechanical Properties: Strength and Flexibility

Vinyl ester resin exhibits superior strength and better flexibility compared to phenolic resin, making it ideal for applications requiring high impact resistance and durability. Phenolic resin, while offering excellent thermal stability and chemical resistance, tends to be more brittle with lower tensile strength. The enhanced mechanical properties of vinyl ester resins contribute to longer service life in demanding structural components.

Thermal Resistance: Performance Under Heat

Vinyl ester resin exhibits excellent thermal resistance with a heat deflection temperature typically around 120-140degC, making it suitable for applications requiring moderate heat endurance. Phenolic resin outperforms vinyl ester resin in high-temperature environments, offering thermal stability up to 180-250degC due to its aromatic backbone and char-forming properties. Phenolic resin's superior flame retardancy and low smoke emission enhance its performance in extreme heat conditions compared to vinyl ester resin.

Corrosion and Chemical Resistance

Vinyl ester resin demonstrates superior corrosion resistance compared to phenolic resin, especially in acidic and alkaline environments, making it ideal for chemical storage tanks and marine applications. Phenolic resin offers excellent chemical resistance to solvents and high temperatures but tends to degrade faster when exposed to strong acids or alkalis. The molecular structure of vinyl ester resin provides enhanced durability against chemical attack, ensuring longer service life in harsh industrial conditions.

Application Areas: Industries and Uses

Vinyl ester resin is widely used in marine, automotive, and chemical processing industries due to its excellent corrosion resistance and mechanical strength, making it ideal for boat hulls, pipelines, and tanks. Phenolic resin is favored in aerospace, electronics, and automotive sectors for its superior heat resistance, flame retardancy, and electrical insulation properties, commonly applied in circuit boards, brake linings, and high-temperature composites. Both resins serve critical roles in manufacturing durable, high-performance components tailored to specific industrial demands.

Fabrication and Processing Techniques

Vinyl ester resin offers superior corrosion resistance and faster curing times, making it ideal for processes such as filament winding, spray-up, and hand lay-up in marine and automotive applications. Phenolic resin, characterized by excellent thermal stability and flame retardancy, is commonly used in compression molding and resin transfer molding (RTM) for aerospace and electrical insulation components. The choice between vinyl ester and phenolic resins depends on required processing temperatures, cure kinetics, and final mechanical properties tailored to specific fabrication techniques.

Cost Analysis and Economic Considerations

Vinyl ester resin generally offers a lower initial cost compared to phenolic resin, making it a more economically feasible option for applications requiring moderate chemical resistance. Phenolic resin, despite its higher upfront price, delivers superior thermal stability and fire resistance, potentially reducing long-term costs in safety-critical environments. Evaluating the total cost of ownership, including material performance and maintenance, is essential for optimizing investment decisions between these two resin types.

Environmental Impact and Safety

Vinyl ester resin offers better chemical resistance and lower toxicity compared to phenolic resin, making it safer for handling and reducing harmful emissions during manufacturing. Phenolic resin, while known for excellent fire resistance and thermal stability, releases formaldehyde and phenol compounds that pose significant environmental and health risks. Vinyl ester resin's improved biodegradability and reduced volatile organic compound (VOC) levels contribute to a lower ecological footprint, supporting sustainable industrial applications.

Choosing the Right Resin: Vinyl Ester or Phenolic?

Vinyl ester resin offers excellent corrosion resistance and flexibility, making it ideal for marine and chemical processing applications, while phenolic resin excels in high-temperature resistance and fire retardancy, suitable for aerospace and electronics industries. Selecting the right resin depends on environmental exposure, mechanical stress, and thermal requirements; vinyl ester resins provide superior toughness and impact resistance, whereas phenolic resins deliver low smoke emission and thermal stability. Careful evaluation of performance criteria such as chemical resistance, heat tolerance, and mechanical strength ensures optimal material choice for specific industrial uses.

Vinyl ester resin vs Phenolic resin Infographic

materialdif.com

materialdif.com