Conductive resin enables efficient electrical conductivity, making it ideal for applications requiring static dissipation or electromagnetic interference shielding. Insulating resin, on the other hand, provides excellent electrical insulation, preventing current flow and protecting sensitive components in electronic devices. Choosing between conductive and insulating resin depends on the specific electrical and mechanical requirements of the project.

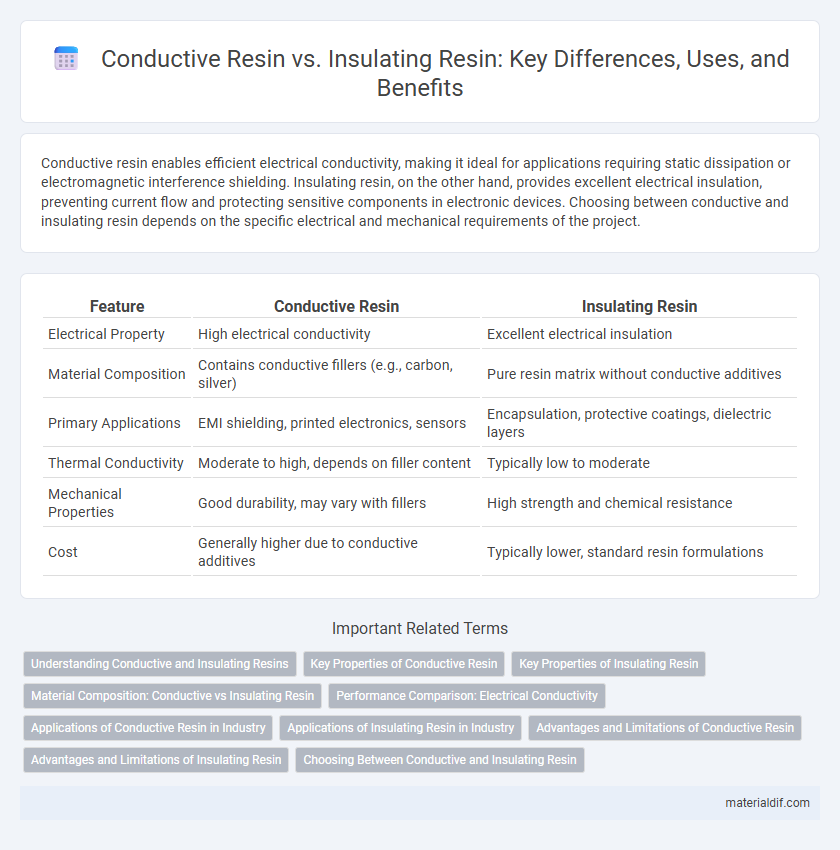

Table of Comparison

| Feature | Conductive Resin | Insulating Resin |

|---|---|---|

| Electrical Property | High electrical conductivity | Excellent electrical insulation |

| Material Composition | Contains conductive fillers (e.g., carbon, silver) | Pure resin matrix without conductive additives |

| Primary Applications | EMI shielding, printed electronics, sensors | Encapsulation, protective coatings, dielectric layers |

| Thermal Conductivity | Moderate to high, depends on filler content | Typically low to moderate |

| Mechanical Properties | Good durability, may vary with fillers | High strength and chemical resistance |

| Cost | Generally higher due to conductive additives | Typically lower, standard resin formulations |

Understanding Conductive and Insulating Resins

Conductive resin contains conductive fillers such as carbon black, silver, or graphite, enabling the material to transmit electrical current, making it ideal for applications in electronics and electromagnetic shielding. Insulating resin, typically composed of epoxy, silicone, or polyester, exhibits high electrical resistance, preventing electrical flow and protecting sensitive components from short circuits and electrical interference. Understanding the electrical properties and material composition of conductive versus insulating resins is crucial for selecting the appropriate resin based on conductivity requirements and thermal stability.

Key Properties of Conductive Resin

Conductive resin is characterized by its ability to allow the flow of electric current due to the incorporation of conductive fillers like carbon black, silver, or graphite, which significantly lower its electrical resistivity. This type of resin exhibits enhanced thermal conductivity and maintains mechanical strength, making it suitable for applications in electronics, electromagnetic interference (EMI) shielding, and flexible circuits. Unlike insulating resin, which offers high electrical resistance and prevents current flow, conductive resin balances conductivity with durability and processability for advanced technological uses.

Key Properties of Insulating Resin

Insulating resin is characterized by its high electrical resistivity, excellent dielectric strength, and thermal stability, making it ideal for preventing electrical conduction in electronic components. Key properties include low dielectric constant and loss, which ensure minimal energy dissipation and enhanced performance in high-frequency applications. Its chemical resistance and mechanical durability further contribute to long-term reliability in various industrial and electronic insulation uses.

Material Composition: Conductive vs Insulating Resin

Conductive resin incorporates materials like carbon black, metal particles, or conductive polymers to facilitate electrical conductivity, enabling its use in electronic components and electromagnetic interference shielding. Insulating resin, composed primarily of non-conductive polymers such as epoxy, polyethylene, or silicone, prevents electrical current flow and is ideal for applications requiring electrical isolation and thermal resistance. The fundamental difference in material composition directly impacts their functional properties, defining their suitability in various industrial and electronic applications.

Performance Comparison: Electrical Conductivity

Conductive resin exhibits significantly higher electrical conductivity, often reaching values between 10^2 to 10^4 S/m, due to the incorporation of conductive fillers such as carbon nanotubes, graphene, or metallic particles. Insulating resin, typically characterized by conductivity below 10^-12 S/m, provides excellent dielectric properties essential for electrical insulation and preventing current leakage. The performance comparison reveals that conductive resins enable efficient current flow in electronic and electromagnetic applications, while insulating resins ensure safety and functionality by maintaining high resistance.

Applications of Conductive Resin in Industry

Conductive resin is widely used in the electronics industry for creating flexible printed circuits, electromagnetic interference (EMI) shielding, and antistatic coatings. Its ability to conduct electricity makes it essential for applications in sensors, wearable devices, and circuit components where traditional insulating resins cannot perform. Industries such as aerospace, automotive, and consumer electronics rely on conductive resin for lightweight, durable, and efficient electrical conductivity solutions.

Applications of Insulating Resin in Industry

Insulating resins play a critical role in the electrical and electronics industry by providing excellent dielectric properties and thermal resistance, essential for manufacturing circuit boards, transformers, and cable coatings. These resins ensure safety and durability by preventing electrical leakage and maintaining insulation under high voltage conditions. Their applications extend to automotive parts, aerospace components, and consumer electronics, where reliable insulation enhances performance and longevity.

Advantages and Limitations of Conductive Resin

Conductive resin offers significant advantages such as enhanced electrical conductivity, making it ideal for applications in electronics, sensors, and EMI shielding. It enables lightweight, flexible components while reducing energy loss and improving device performance. However, limitations include higher production costs, potential reduced mechanical strength, and sensitivity to environmental factors like moisture and temperature changes.

Advantages and Limitations of Insulating Resin

Insulating resin offers excellent electrical resistance and thermal stability, making it ideal for applications requiring effective isolation and protection against electrical currents. Its advantages include high dielectric strength, chemical resistance, and durability in harsh environments, which prevent short circuits and enhance the lifespan of electronic components. However, insulating resin limitations include lower thermal conductivity compared to conductive resins, restricting heat dissipation and potentially leading to overheating in high-power devices.

Choosing Between Conductive and Insulating Resin

Choosing between conductive and insulating resin depends on the specific electrical requirements of your project. Conductive resin contains fillers like carbon or metal particles that enable electrical flow, making it ideal for applications such as electromagnetic shielding and circuit components. Insulating resin, typically composed of polymers like epoxy or silicone, offers excellent dielectric properties and thermal resistance, suitable for preventing electrical conduction and protecting sensitive electronics.

Conductive Resin vs Insulating Resin Infographic

materialdif.com

materialdif.com