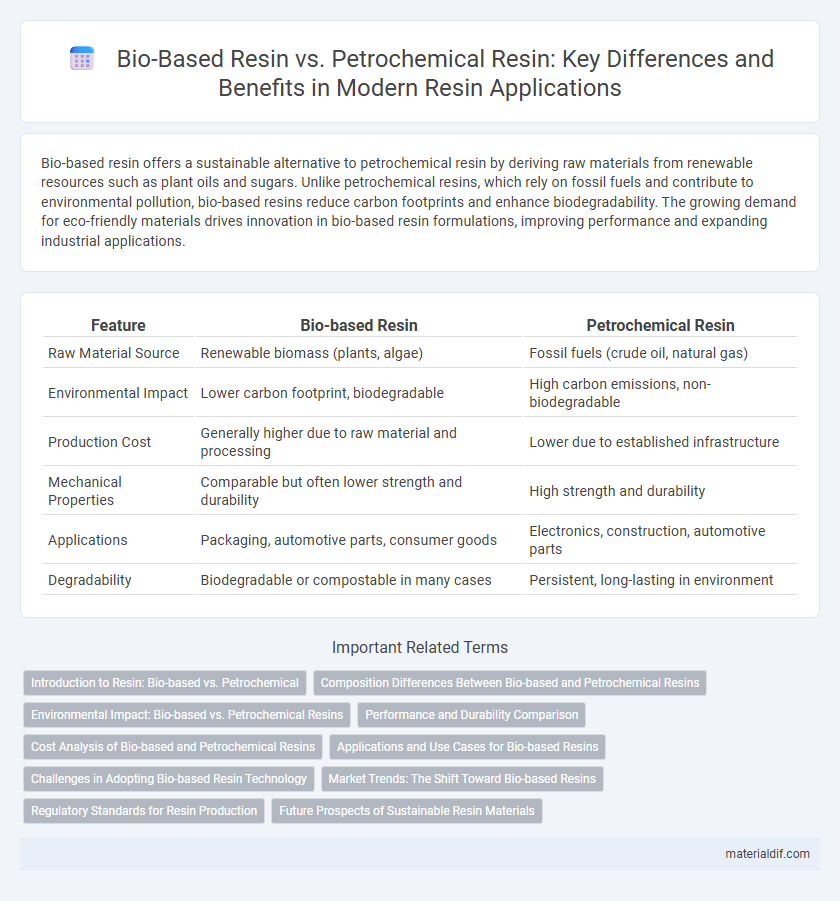

Bio-based resin offers a sustainable alternative to petrochemical resin by deriving raw materials from renewable resources such as plant oils and sugars. Unlike petrochemical resins, which rely on fossil fuels and contribute to environmental pollution, bio-based resins reduce carbon footprints and enhance biodegradability. The growing demand for eco-friendly materials drives innovation in bio-based resin formulations, improving performance and expanding industrial applications.

Table of Comparison

| Feature | Bio-based Resin | Petrochemical Resin |

|---|---|---|

| Raw Material Source | Renewable biomass (plants, algae) | Fossil fuels (crude oil, natural gas) |

| Environmental Impact | Lower carbon footprint, biodegradable | High carbon emissions, non-biodegradable |

| Production Cost | Generally higher due to raw material and processing | Lower due to established infrastructure |

| Mechanical Properties | Comparable but often lower strength and durability | High strength and durability |

| Applications | Packaging, automotive parts, consumer goods | Electronics, construction, automotive parts |

| Degradability | Biodegradable or compostable in many cases | Persistent, long-lasting in environment |

Introduction to Resin: Bio-based vs. Petrochemical

Bio-based resin is derived from renewable biological sources such as plant oils, starches, and cellulose, offering a sustainable alternative to traditional petrochemical resins made from fossil fuels like crude oil and natural gas. Petrochemical resins are known for their durability, scalability, and cost-effectiveness but contribute significantly to environmental pollution and carbon emissions. The shift towards bio-based resins aims to reduce reliance on non-renewable resources and lower the carbon footprint while maintaining comparable performance characteristics in various industrial applications.

Composition Differences Between Bio-based and Petrochemical Resins

Bio-based resins primarily consist of renewable organic materials such as plant oils, starches, and cellulose, offering a sustainable alternative to petrochemical resins derived from fossil fuels like petroleum and natural gas. The molecular structure of bio-based resins often includes biodegradable and carbon-neutral components, unlike petrochemical resins that are typically composed of long hydrocarbon chains with limited biodegradability. These compositional differences impact the performance, environmental footprint, and applications of the resins in industries ranging from packaging to automotive manufacturing.

Environmental Impact: Bio-based vs. Petrochemical Resins

Bio-based resins significantly reduce carbon emissions by utilizing renewable biomass sources, leading to lower environmental footprints compared to petrochemical resins derived from fossil fuels. Petrochemical resins contribute to greenhouse gas emissions and environmental pollution through extraction and refining processes. Lifecycle analyses demonstrate bio-based resins offer enhanced biodegradability and reduced dependency on finite resources, promoting sustainable material usage.

Performance and Durability Comparison

Bio-based resin often demonstrates comparable mechanical properties to petrochemical resin but excels in biodegradability and reduced environmental impact. Petrochemical resins typically offer superior heat resistance and long-term durability under harsh conditions. Advances in bio-based resin formulations are closing the gap in performance, enhancing their viability for industrial applications requiring high strength and longevity.

Cost Analysis of Bio-based and Petrochemical Resins

Bio-based resins generally exhibit higher production costs compared to petrochemical resins due to limited raw material availability and less established manufacturing processes. Petrochemical resins benefit from economies of scale and mature infrastructure, resulting in lower unit costs and greater market competitiveness. Cost variations also depend on feedstock prices, processing technology, and regional supply chain efficiencies impacting overall economic viability.

Applications and Use Cases for Bio-based Resins

Bio-based resins are increasingly utilized in automotive components, packaging materials, and consumer goods due to their renewable origins and reduced carbon footprint. These resins offer comparable performance to petrochemical resins in applications such as biodegradable packaging, sustainable textiles, and electronic casings. Growing demand for eco-friendly alternatives drives innovation in bio-based resins tailored for food containers, insulation materials, and medical devices.

Challenges in Adopting Bio-based Resin Technology

Bio-based resin faces significant challenges in adoption due to higher production costs compared to petrochemical resin, limiting its economic competitiveness. Supply chain constraints and variability in raw materials impact consistent quality and scalability for industrial applications. Furthermore, existing infrastructure and processing technologies are optimized for petrochemical resins, requiring substantial modifications to accommodate bio-based alternatives.

Market Trends: The Shift Toward Bio-based Resins

The global resin market is experiencing a significant shift toward bio-based resins driven by increasing environmental regulations and consumer demand for sustainable materials. Bio-based resins, derived from renewable resources such as corn, sugarcane, and cellulose, are gaining market share due to their lower carbon footprint and biodegradability compared to traditional petrochemical resins. Industry forecasts predict a compound annual growth rate (CAGR) exceeding 10% for bio-based resins through 2030, reflecting a broader trend toward circular economy principles in plastics manufacturing.

Regulatory Standards for Resin Production

Bio-based resin production increasingly aligns with stringent regulatory standards focused on sustainability, biodegradability, and reduced carbon footprint, promoting compliance with international frameworks like REACH and the EU Bioplastics Directive. Petrochemical resin manufacturing remains subject to rigorous regulations concerning hazardous emissions, volatile organic compounds (VOCs), and chemical safety under agencies such as the U.S. EPA and OSHA. Emerging policies emphasize lifecycle assessments and eco-label certifications, driving innovation in both resin types to meet evolving environmental and health safety criteria.

Future Prospects of Sustainable Resin Materials

Bio-based resins derived from renewable resources like plant oils and starches offer promising sustainability advantages over conventional petrochemical resins, including reduced carbon footprint and biodegradability. Advances in biotechnology and green chemistry are driving improvements in the performance and cost-efficiency of bio-based resin formulations, enabling wider industrial adoption. As global regulations tighten and consumer demand shifts toward eco-friendly materials, bio-based resins are poised to capture a significant share of the sustainable resin market in the coming decade.

Bio-based resin vs Petrochemical resin Infographic

materialdif.com

materialdif.com