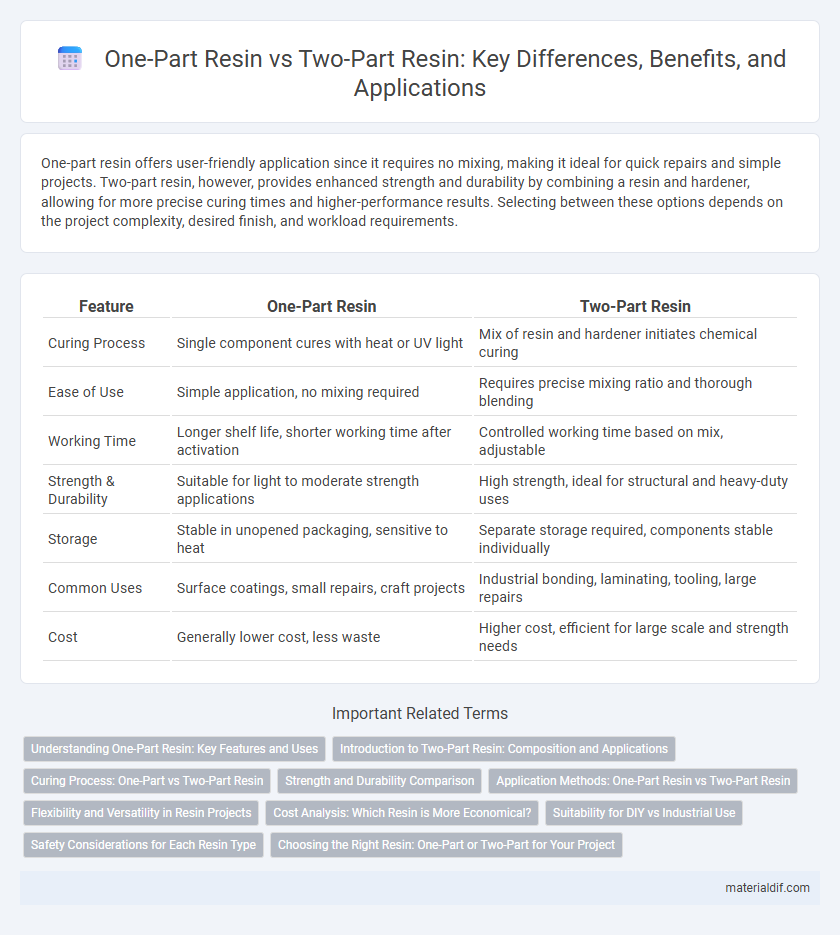

One-part resin offers user-friendly application since it requires no mixing, making it ideal for quick repairs and simple projects. Two-part resin, however, provides enhanced strength and durability by combining a resin and hardener, allowing for more precise curing times and higher-performance results. Selecting between these options depends on the project complexity, desired finish, and workload requirements.

Table of Comparison

| Feature | One-Part Resin | Two-Part Resin |

|---|---|---|

| Curing Process | Single component cures with heat or UV light | Mix of resin and hardener initiates chemical curing |

| Ease of Use | Simple application, no mixing required | Requires precise mixing ratio and thorough blending |

| Working Time | Longer shelf life, shorter working time after activation | Controlled working time based on mix, adjustable |

| Strength & Durability | Suitable for light to moderate strength applications | High strength, ideal for structural and heavy-duty uses |

| Storage | Stable in unopened packaging, sensitive to heat | Separate storage required, components stable individually |

| Common Uses | Surface coatings, small repairs, craft projects | Industrial bonding, laminating, tooling, large repairs |

| Cost | Generally lower cost, less waste | Higher cost, efficient for large scale and strength needs |

Understanding One-Part Resin: Key Features and Uses

One-part resin is a pre-mixed formulation that solidifies upon exposure to air or heat, eliminating the need for manual mixing and reducing application errors. Its ease of use and consistent cure time make it ideal for small repairs, coatings, and casting applications where precision and convenience are critical. Commonly used in DIY projects and industrial maintenance, one-part resin offers fast curing and strong adhesion on surfaces like metals, plastics, and wood.

Introduction to Two-Part Resin: Composition and Applications

Two-part resin consists of a resin base and a hardener that chemically react when mixed, creating a strong, curing compound ideal for industrial and artistic applications. This composition provides enhanced durability, heat resistance, and bonding strength compared to one-part resins, making it suitable for casting, adhesives, and coatings in automotive, aerospace, and marine industries. The versatility of two-part resin allows for precise control over curing time and mechanical properties, meeting diverse manufacturing and repair requirements.

Curing Process: One-Part vs Two-Part Resin

One-part resin cures through exposure to air or heat, initiating a polymerization process that solidifies the material without mixing components. Two-part resin requires precise mixing of a resin and a hardener, triggering a chemical reaction that cures the material within a specific timeframe. The two-part system generally offers faster curing and stronger mechanical properties compared to the slower, air or heat-activated curing of one-part resin.

Strength and Durability Comparison

One-part resin offers ease of use with moderate strength and durability suitable for light repairs and crafting, while two-part resin combines a resin and hardener for a chemical reaction that produces a much stronger and more durable bond, ideal for industrial applications and heavy-duty repairs. Two-part resin typically exhibits superior resistance to impact, heat, and chemicals compared to the single-component option. The enhanced mechanical properties of two-part resin make it the preferred choice for structural bonding and long-term performance.

Application Methods: One-Part Resin vs Two-Part Resin

One-part resin cures through exposure to air, heat, or UV light, simplifying the application process and reducing preparation time, making it ideal for quick repairs and user-friendly projects. Two-part resin requires mixing a resin base with a hardener in precise ratios before application, offering superior control over curing speed and mechanical properties, suitable for more demanding industrial or artistic applications. Understanding the distinct curing mechanisms and mixing requirements is essential for selecting the appropriate resin type based on project complexity and desired finish.

Flexibility and Versatility in Resin Projects

One-part resin offers ease of use and quick curing, making it suitable for flexible projects with simple applications, but it may lack versatility in complex or multi-layered designs. Two-part resin provides enhanced flexibility and adaptability, allowing precise control over curing time and hardness, which is ideal for detailed, layered, or high-strength projects. Selecting between one-part and two-part resin depends on the project's requirements for flexibility, durability, and artistic complexity.

Cost Analysis: Which Resin is More Economical?

One-part resin typically offers lower upfront costs due to its simpler packaging and ease of use, making it more economical for small-scale or hobby projects. Two-part resin, despite higher initial costs from separate resin and hardener components, provides superior strength, durability, and longer shelf life, often reducing material waste and repair expenses over time. Cost-effectiveness depends on project complexity, volume, and desired performance, with one-part resin favoring budget-conscious users and two-part resin benefiting industrial or professional applications.

Suitability for DIY vs Industrial Use

One-part resin offers simplicity and ease of use, making it ideal for DIY projects due to its pre-mixed formulation that cures with exposure to air or heat, reducing handling complexity. Two-part resin, comprising resin and hardener, provides superior strength and durability, favoring industrial applications where precise mixing ratios and controlled curing conditions are essential for structural integrity. DIY enthusiasts benefit from one-part resin's convenience and user-friendly application, while two-part resin's robust performance supports the demanding requirements of professional manufacturing and repair tasks.

Safety Considerations for Each Resin Type

One-part resin generally offers a safer handling experience due to its pre-mixed formulation that minimizes exposure to potentially harmful chemicals, making it ideal for beginners and small projects. In contrast, two-part resin requires careful mixing of resin and hardener, posing greater risks such as skin irritation and toxic fumes, thus necessitating proper ventilation, gloves, and eye protection. Understanding these safety considerations is crucial to prevent chemical burns and respiratory issues during resin use.

Choosing the Right Resin: One-Part or Two-Part for Your Project

One-part resin offers ease of use with pre-mixed formulas ideal for small or quick projects, providing consistent curing without the need for precise measurement. Two-part resin requires mixing resin and hardener in specific ratios, delivering higher strength, durability, and chemical resistance suited for large-scale or professional applications. Selecting the right resin depends on project complexity, desired mechanical properties, and curing time, with one-part resins favored for simplicity and two-part resins preferred for superior performance.

One-Part Resin vs Two-Part Resin Infographic

materialdif.com

materialdif.com