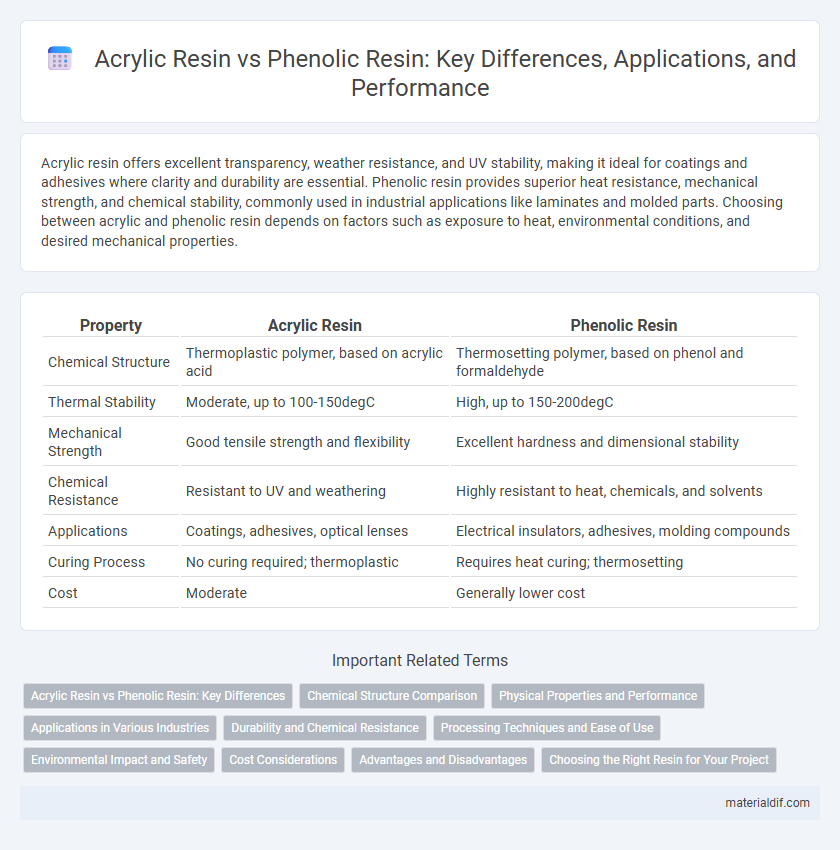

Acrylic resin offers excellent transparency, weather resistance, and UV stability, making it ideal for coatings and adhesives where clarity and durability are essential. Phenolic resin provides superior heat resistance, mechanical strength, and chemical stability, commonly used in industrial applications like laminates and molded parts. Choosing between acrylic and phenolic resin depends on factors such as exposure to heat, environmental conditions, and desired mechanical properties.

Table of Comparison

| Property | Acrylic Resin | Phenolic Resin |

|---|---|---|

| Chemical Structure | Thermoplastic polymer, based on acrylic acid | Thermosetting polymer, based on phenol and formaldehyde |

| Thermal Stability | Moderate, up to 100-150degC | High, up to 150-200degC |

| Mechanical Strength | Good tensile strength and flexibility | Excellent hardness and dimensional stability |

| Chemical Resistance | Resistant to UV and weathering | Highly resistant to heat, chemicals, and solvents |

| Applications | Coatings, adhesives, optical lenses | Electrical insulators, adhesives, molding compounds |

| Curing Process | No curing required; thermoplastic | Requires heat curing; thermosetting |

| Cost | Moderate | Generally lower cost |

Acrylic Resin vs Phenolic Resin: Key Differences

Acrylic resin offers superior clarity, UV resistance, and weather durability compared to phenolic resin, which excels in heat resistance and mechanical strength. Acrylic resin's chemical structure provides excellent transparency and color retention, making it ideal for coatings, adhesives, and optical applications. Phenolic resin's thermosetting properties deliver robust thermal stability and flame retardance, commonly used in industrial laminates and electrical components.

Chemical Structure Comparison

Acrylic resin features a polymer backbone primarily composed of repeating acrylate or methacrylate units, characterized by carbon-carbon double bonds that provide flexibility and clarity. Phenolic resin consists of a complex network formed through the polymerization of phenol and formaldehyde, resulting in a thermosetting structure with high cross-link density and excellent heat resistance. The chemical structure difference impacts properties such as transparency, mechanical strength, and thermal stability, making acrylic resins suitable for coatings and adhesives, while phenolic resins are favored for high-temperature and structural applications.

Physical Properties and Performance

Acrylic resin exhibits superior clarity, impact resistance, and UV stability, making it ideal for applications requiring transparency and weather resistance. Phenolic resin offers excellent thermal stability, chemical resistance, and mechanical strength, excelling in high-temperature and industrial environments. While acrylic resin provides flexibility and aesthetic appeal, phenolic resin delivers durability and flame retardancy for demanding performance conditions.

Applications in Various Industries

Acrylic resin is widely used in automotive coatings, adhesives, and transparent barriers due to its excellent clarity and UV resistance, while phenolic resin excels in electrical insulation, brake pads, and abrasive applications because of its high thermal stability and mechanical strength. Industries such as construction and electronics favor acrylic resin for its weather resistance and aesthetic appeal, whereas phenolic resin is preferred in aerospace and industrial manufacturing for its durability under extreme conditions. The choice between acrylic and phenolic resins depends on specific application requirements including environmental exposure, mechanical load, and thermal resistance.

Durability and Chemical Resistance

Acrylic resin offers excellent weather resistance and maintains clarity over time, making it highly durable for outdoor applications, while phenolic resin excels in high-heat environments due to its superior thermal stability and rigidity. Phenolic resin demonstrates exceptional chemical resistance, particularly against acids and solvents, whereas acrylic resin resists UV radiation and maintains color stability better. The choice between acrylic and phenolic resins depends on specific durability requirements and chemical exposure conditions in the intended use.

Processing Techniques and Ease of Use

Acrylic resins are favored for their ease of processing using techniques such as injection molding and extrusion due to their lower melting points and superior flow characteristics. Phenolic resins require more complex processing methods, including compression molding and heat curing, due to their high-temperature resistance and thermosetting nature. Acrylic resins offer faster cycle times and simpler handling, making them more user-friendly in manufacturing environments.

Environmental Impact and Safety

Acrylic resin exhibits low toxicity and is more environmentally friendly due to its lower emission of volatile organic compounds (VOCs) during curing and degradation, making it safer for indoor applications and reducing air pollution. Phenolic resin, while offering excellent heat resistance and chemical stability, releases formaldehyde and phenol substances, which pose significant health risks and contribute to environmental hazards through air and water contamination. Choosing acrylic resin over phenolic resin can significantly mitigate harmful emissions and improve workplace safety standards in manufacturing processes.

Cost Considerations

Acrylic resin typically offers a lower initial cost compared to phenolic resin, making it suitable for budget-sensitive applications. Phenolic resin, while more expensive upfront, provides superior thermal stability and chemical resistance, which can reduce long-term maintenance and replacement costs. Cost considerations should balance immediate expenditure with durability and performance requirements for optimal value.

Advantages and Disadvantages

Acrylic resin offers superior clarity, UV resistance, and excellent weatherability, making it ideal for outdoor applications and coatings, but it tends to have lower heat resistance and mechanical strength compared to phenolic resin. Phenolic resin provides outstanding thermal stability, flame resistance, and rigidity, which is advantageous in high-temperature environments and electrical insulation, yet it can be brittle and less transparent, limiting its use in aesthetic applications. Choosing between acrylic and phenolic resins depends on balancing optical clarity and weather resistance against thermal performance and mechanical durability.

Choosing the Right Resin for Your Project

Acrylic resin offers excellent clarity, UV resistance, and flexibility, making it ideal for applications like coatings, adhesives, and optical devices. Phenolic resin provides superior heat resistance, mechanical strength, and chemical stability, suited for high-temperature environments and industrial molds. Selecting the right resin depends on project requirements such as durability, environmental exposure, and thermal performance.

Acrylic Resin vs Phenolic Resin Infographic

materialdif.com

materialdif.com