Marine resin is specially formulated to withstand harsh saltwater environments, offering superior UV resistance, durability, and protection against moisture intrusion, making it ideal for boat repairs and marine applications. Art resin prioritizes clarity, non-yellowing properties, and ease of use, providing a glossy, high-gloss finish perfect for creative projects like coating paintings and jewelry. Choosing the right resin depends on the intended application environment and the desired aesthetic and performance characteristics.

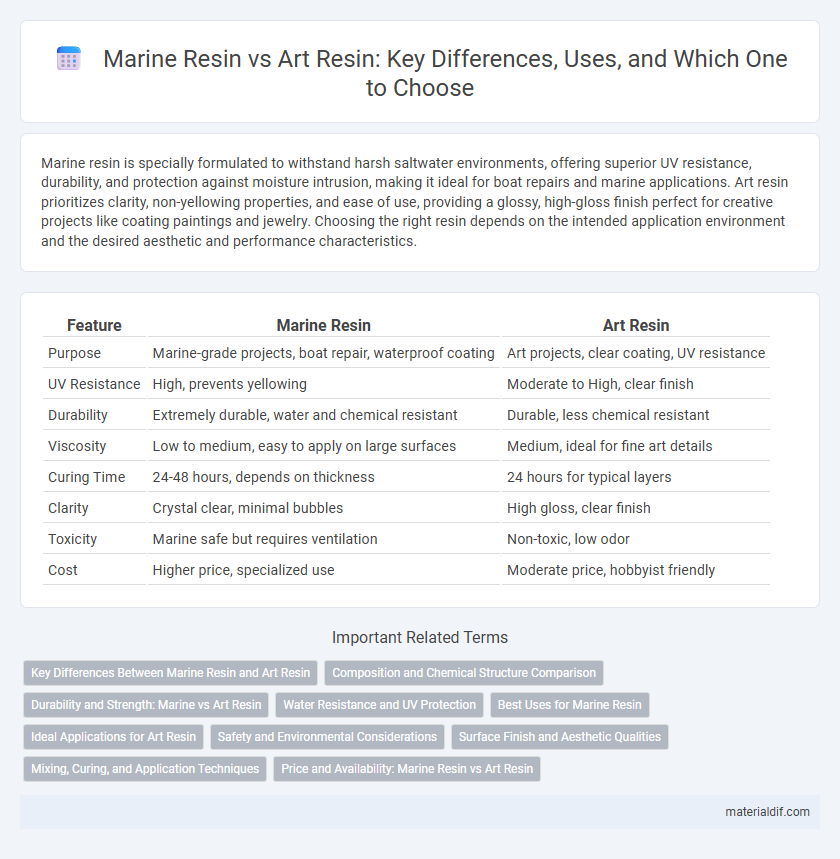

Table of Comparison

| Feature | Marine Resin | Art Resin |

|---|---|---|

| Purpose | Marine-grade projects, boat repair, waterproof coating | Art projects, clear coating, UV resistance |

| UV Resistance | High, prevents yellowing | Moderate to High, clear finish |

| Durability | Extremely durable, water and chemical resistant | Durable, less chemical resistant |

| Viscosity | Low to medium, easy to apply on large surfaces | Medium, ideal for fine art details |

| Curing Time | 24-48 hours, depends on thickness | 24 hours for typical layers |

| Clarity | Crystal clear, minimal bubbles | High gloss, clear finish |

| Toxicity | Marine safe but requires ventilation | Non-toxic, low odor |

| Cost | Higher price, specialized use | Moderate price, hobbyist friendly |

Key Differences Between Marine Resin and Art Resin

Marine resin is specifically engineered for harsh aquatic environments, offering superior UV resistance, water impermeability, and durability against saltwater corrosion, making it ideal for boat repairs and marine applications. Art resin prioritizes clarity, non-yellowing properties, and ease of use for decorative projects, providing a glossy finish and enhanced color vibrancy suitable for crafts and artwork. The key differences lie in marine resin's robust chemical composition for environmental resistance versus art resin's aesthetic focus and user-friendly curing process.

Composition and Chemical Structure Comparison

Marine resin typically consists of a polyol and isocyanate compound forming a polyurethane network, designed for high resistance to saltwater, UV exposure, and mechanical stress. Art resin is usually an epoxy-based system composed of bisphenol-A or bisphenol-F epoxy resins combined with amine hardeners, optimized for clarity, gloss, and curing control. The chemical structure of marine resin prioritizes hydrophobic chains and crosslink density to withstand corrosive marine environments, whereas art resin emphasizes molecular weight and epoxy group concentration to achieve superior adhesion and optical clarity.

Durability and Strength: Marine vs Art Resin

Marine resin is specifically formulated to withstand harsh saltwater environments, offering superior UV resistance, corrosion protection, and enhanced durability against wear and tear compared to art resin. Art resin, while providing excellent clarity and a smooth finish, lacks the robust chemical resistance and impact strength required for prolonged exposure to marine conditions. The specialized additives in marine resin significantly improve tensile strength and longevity, making it ideal for boat repairs and underwater applications, unlike art resin which is optimized for aesthetic projects.

Water Resistance and UV Protection

Marine resin offers superior water resistance and UV protection, making it ideal for applications exposed to harsh marine environments and prolonged sun exposure. Art resin, while water-resistant and UV-stable, is primarily designed for aesthetic purposes and indoor use, providing moderate durability against moisture and sunlight. Choosing marine resin ensures enhanced longevity for outdoor or underwater projects, whereas art resin suits decorative items with limited exposure to the elements.

Best Uses for Marine Resin

Marine resin is specially formulated for superior water resistance, UV stability, and durability in harsh marine environments, making it ideal for boat repairs, fiberglass applications, and outdoor marine structures. Its capacity to withstand saltwater corrosion and prolonged exposure to moisture ensures long-lasting performance compared to standard art resins. Best uses include sealing and bonding on boats, kayak hulls, and other watercraft where structural integrity and protection against water damage are critical.

Ideal Applications for Art Resin

Art Resin is specifically formulated for creative projects such as coating paintings, embedding objects, and creating jewelry due to its crystal-clear finish and UV resistance. Unlike Marine Resin, which is designed for durability and water resistance in harsh marine environments, Art Resin provides a non-yellowing, glossy surface ideal for indoor art displays. Its self-leveling and bubble-resistant properties make it the preferred choice for artists seeking professional-quality results.

Safety and Environmental Considerations

Marine resin typically offers enhanced UV resistance and durability, making it suitable for harsh marine environments but may contain chemicals with higher VOC emissions impacting indoor air quality. Art resin is formulated for safer indoor use, often featuring low-odor, non-toxic properties and reduced VOC content, catering to artists' health concerns. Both resins require proper ventilation and disposal methods to minimize environmental impact and ensure user safety.

Surface Finish and Aesthetic Qualities

Marine resin delivers exceptional surface durability and UV resistance, making it ideal for outdoor applications with a glossy, weatherproof finish that resists yellowing. Art resin emphasizes clarity and self-leveling properties, producing a smooth, high-gloss surface that enhances color vibrancy and detail in creative projects. Both resins provide visually appealing finishes, but marine resin prioritizes protective qualities while art resin focuses on aesthetic precision.

Mixing, Curing, and Application Techniques

Marine resin, formulated for high durability and UV resistance, typically requires precise mixing ratios to ensure optimal curing and structural integrity in harsh marine environments. Art resin, designed for clarity and self-leveling properties, demands careful temperature control during mixing to prevent bubbles and uneven curing, enhancing its aesthetic finish for creative applications. Marine resin often involves specialized curing processes like heat curing for strength, while art resin benefits from room-temperature curing and techniques like layering or embedding for detailed artistic effects.

Price and Availability: Marine Resin vs Art Resin

Marine resin typically commands a higher price due to its specialized formulation for durability in harsh marine environments, including UV resistance and moisture protection. Availability of marine resin can be limited compared to art resin, as it is primarily sold through marine supply stores and specialized distributors. Art resin is more widely available in craft stores and online, offering a more affordable option suitable for decorative projects but lacking the robust properties required for marine applications.

Marine Resin vs Art Resin Infographic

materialdif.com

materialdif.com