Resin infusion offers superior composite strength and consistency compared to wet layup by using vacuum pressure to evenly distribute resin through dry fabric, minimizing voids and reducing emissions. Wet layup is a more straightforward, cost-effective technique where resin is manually applied to fabric layers, but it often results in heavier, less uniform parts with potential for air entrapment. Choosing resin infusion over wet layup enhances durability and performance, making it ideal for high-quality, complex resin pet projects.

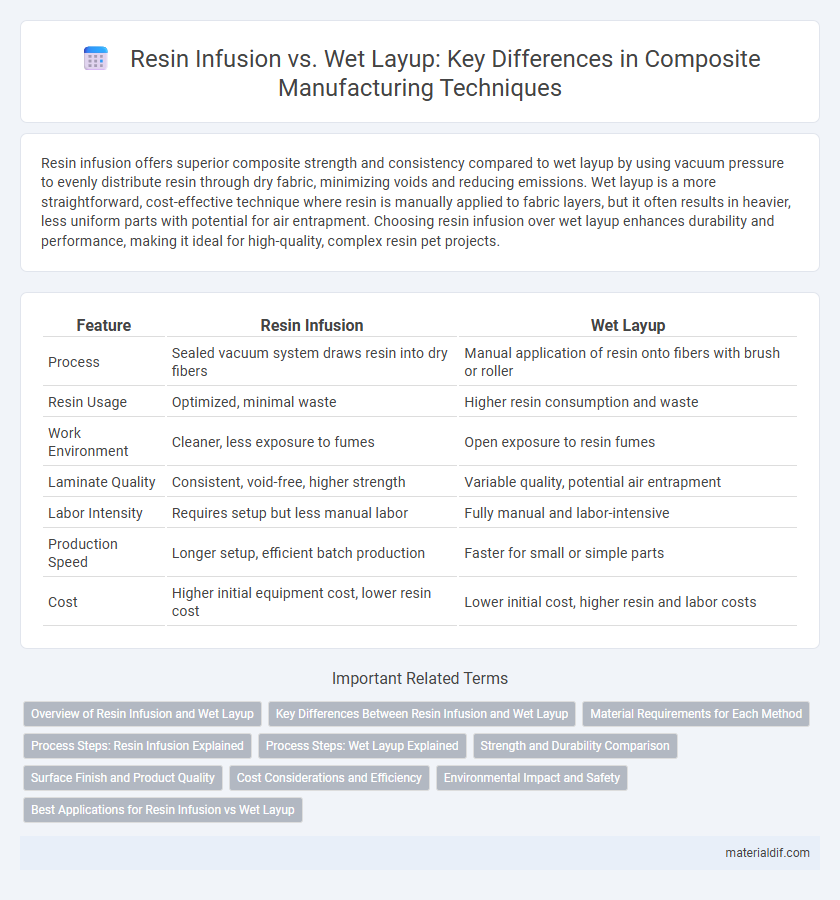

Table of Comparison

| Feature | Resin Infusion | Wet Layup |

|---|---|---|

| Process | Sealed vacuum system draws resin into dry fibers | Manual application of resin onto fibers with brush or roller |

| Resin Usage | Optimized, minimal waste | Higher resin consumption and waste |

| Work Environment | Cleaner, less exposure to fumes | Open exposure to resin fumes |

| Laminate Quality | Consistent, void-free, higher strength | Variable quality, potential air entrapment |

| Labor Intensity | Requires setup but less manual labor | Fully manual and labor-intensive |

| Production Speed | Longer setup, efficient batch production | Faster for small or simple parts |

| Cost | Higher initial equipment cost, lower resin cost | Lower initial cost, higher resin and labor costs |

Overview of Resin Infusion and Wet Layup

Resin infusion is a closed-mold process that uses vacuum pressure to draw resin into dry reinforcement, resulting in stronger, lighter composite parts with minimal voids and emissions. Wet layup, an open-mold technique, involves manually applying resin to reinforcement materials, which can lead to higher resin content and potential inconsistencies in fiber saturation. Resin infusion offers enhanced control over resin distribution and improved structural integrity compared to the more labor-intensive and variable wet layup process.

Key Differences Between Resin Infusion and Wet Layup

Resin infusion utilizes vacuum pressure to draw resin through dry fiber reinforcements, resulting in a higher fiber-to-resin ratio and superior structural strength, whereas wet layup involves manually saturating fibers with resin, often leading to increased resin content and heavier parts. Resin infusion offers better control over resin distribution, reduced void content, and improved repeatability compared to the more labor-intensive and less consistent wet layup process. The infusion method is widely preferred in industries requiring high-performance composites, such as aerospace and marine, due to its enhanced mechanical properties and environmental benefits.

Material Requirements for Each Method

Resin infusion requires dry reinforcement materials and vacuum bagging film to create an airtight seal, allowing resin to be drawn through the fiber layers efficiently. Wet layup demands pre-impregnated or dry fibers directly wetted with resin, usually necessitating brushes or rollers for manual application. The controlled resin flow in resin infusion minimizes material waste compared to the excess resin often used in wet layup processes.

Process Steps: Resin Infusion Explained

Resin infusion involves sealing dry fiber reinforcements within a vacuum bag before drawing resin through the fibers using vacuum pressure, ensuring thorough saturation and minimal voids. This process includes placing the dry fabric, laying a distribution mesh, sealing with a vacuum bag, and carefully infusing resin to achieve consistent fiber wet-out and enhanced mechanical properties. Unlike wet layup, resin infusion improves resin control, reduces emissions, and yields stronger, lighter composite parts suitable for aerospace and automotive applications.

Process Steps: Wet Layup Explained

Wet layup involves manually saturating reinforcement fibers with resin using brushes or rollers before laying them into the mold, allowing for flexible shaping and detailed work. The process includes applying resin directly onto the fibers, consolidating layers by hand to remove air pockets, and curing at ambient temperature or with heat. This technique is preferred for small-scale or custom applications due to its straightforward steps and lower equipment requirements compared to resin infusion.

Strength and Durability Comparison

Resin infusion delivers superior strength and durability compared to wet layup due to its controlled resin-to-fiber ratio and reduced void content, resulting in higher laminate quality. The vacuum-assisted process ensures optimal resin distribution and minimizes air entrapment, enhancing mechanical properties such as tensile strength and impact resistance. Wet layup often shows variability in resin content and potential for weak spots, leading to less consistent performance under stress and environmental exposure.

Surface Finish and Product Quality

Resin infusion produces a superior surface finish with fewer air bubbles and voids compared to wet layup, resulting in a more consistent and high-quality composite product. The controlled resin flow in resin infusion ensures uniform resin distribution, enhancing mechanical properties and reducing the likelihood of defects. Wet layup often leads to uneven resin content and visible surface imperfections, compromising overall product durability and aesthetic appeal.

Cost Considerations and Efficiency

Resin infusion typically offers higher initial setup costs due to equipment requirements but reduces resin waste and labor expenses through precise resin control, enhancing overall cost-efficiency for large or complex projects. Wet layup involves lower upfront investment but often results in greater resin consumption and longer cure times, leading to increased labor costs and potential material waste. Efficiency in resin infusion also stems from improved laminate quality and reduced rework, making it a cost-effective choice despite higher initial expenditure.

Environmental Impact and Safety

Resin infusion significantly reduces the release of volatile organic compounds (VOCs) compared to wet layup, minimizing environmental pollution and worker exposure to hazardous fumes. The closed mold process in resin infusion lowers emissions and waste resin runoff, enhancing safety and sustainability in composite manufacturing. In contrast, wet layup involves open handling of resins, increasing risks of skin contact, inhalation of toxic vapors, and environmental contamination.

Best Applications for Resin Infusion vs Wet Layup

Resin infusion is best suited for large, complex composite structures requiring high strength-to-weight ratios and superior resin control, such as aerospace components and high-performance marine vessels. Wet layup is ideal for smaller, simpler projects like repair work or prototyping where quick curing and lower equipment costs are priorities. Infusion offers enhanced consistency and reduced void content, while wet layup provides greater flexibility and faster turnaround for limited production runs.

Resin Infusion vs Wet Layup Infographic

materialdif.com

materialdif.com