Random copolymer polypropylene offers enhanced clarity and flexibility, making it ideal for applications requiring transparency and softness, while impact copolymer polypropylene provides superior impact resistance and toughness due to its rubber-modified structure. The random copolymer's amorphous regions improve optical properties and low-temperature performance, whereas the impact copolymer's dispersed rubber phase absorbs energy to prevent cracking under stress. Manufacturers choose between random and impact copolymers based on the balance needed between clarity and mechanical strength for specific polypropylene product applications.

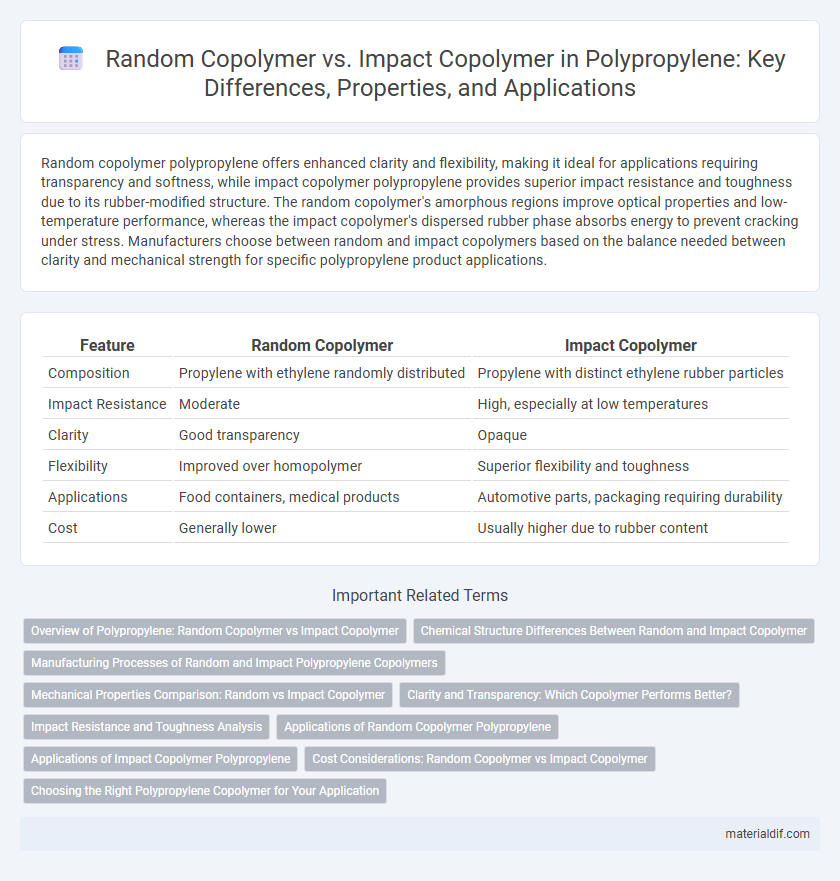

Table of Comparison

| Feature | Random Copolymer | Impact Copolymer |

|---|---|---|

| Composition | Propylene with ethylene randomly distributed | Propylene with distinct ethylene rubber particles |

| Impact Resistance | Moderate | High, especially at low temperatures |

| Clarity | Good transparency | Opaque |

| Flexibility | Improved over homopolymer | Superior flexibility and toughness |

| Applications | Food containers, medical products | Automotive parts, packaging requiring durability |

| Cost | Generally lower | Usually higher due to rubber content |

Overview of Polypropylene: Random Copolymer vs Impact Copolymer

Random copolymer polypropylene features a homogeneous molecular structure with ethylene distributed randomly along the polymer chain, resulting in improved clarity, flexibility, and gloss, making it ideal for applications like medical packaging and food containers. Impact copolymer polypropylene incorporates distinct ethylene-propylene rubber phases that enhance toughness and impact resistance, suited for automotive parts, appliances, and heavy-duty packaging. The primary difference lies in the ethylene content distribution and mechanical properties, with random copolymers prioritizing optical clarity and impact copolymers optimizing strength and durability.

Chemical Structure Differences Between Random and Impact Copolymer

Random copolymer polypropylene consists of propylene units randomly distributed with ethylene units, resulting in a more amorphous structure and enhanced clarity. Impact copolymer polypropylene features a distinct two-phase morphology with a crystalline polypropylene matrix and dispersed rubbery ethylene-propylene copolymer particles, providing improved impact resistance. The chemical structure difference lies in the random incorporation of ethylene in random copolymers versus the block-like distribution of ethylene-propylene segments in impact copolymers.

Manufacturing Processes of Random and Impact Polypropylene Copolymers

Random polypropylene copolymers are manufactured through the copolymerization of propylene with a small amount of ethylene under controlled temperature and pressure, resulting in a polymer chain with ethylene units dispersed randomly to enhance clarity and flexibility. Impact polypropylene copolymers are produced using a two-step polymerization process, starting with the formation of a polypropylene homopolymer matrix followed by the incorporation of rubbery ethylene-propylene copolymer particles to improve impact resistance. The distinct catalyst systems and reaction conditions in each process influence the molecular architecture and resultant physical properties of the copolymers.

Mechanical Properties Comparison: Random vs Impact Copolymer

Random copolymer polypropylene offers enhanced clarity and flexibility due to its amorphous structure, resulting in moderate impact resistance and improved tensile strength. Impact copolymer polypropylene incorporates rubbery ethylene segments, significantly increasing toughness and impact resistance, especially at low temperatures, while maintaining good stiffness. Mechanical properties of impact copolymers surpass random copolymers in impact strength, making them ideal for applications requiring durability and high-performance under stress.

Clarity and Transparency: Which Copolymer Performs Better?

Random copolymer polypropylene offers superior clarity and transparency due to its more uniform molecular structure, making it ideal for applications requiring clear packaging and medical containers. Impact copolymer polypropylene contains rubber-like ethylene segments that enhance toughness but reduce optical clarity, resulting in a more opaque material. For optimal transparency, random copolymer is the preferred choice over impact copolymer in polypropylene applications.

Impact Resistance and Toughness Analysis

Impact copolymer polypropylene features enhanced impact resistance and toughness due to the incorporation of ethylene-propylene rubber phases, which absorb and dissipate energy during stress. Random copolymer polypropylene offers moderate toughness but tends to be less resilient under high-impact conditions because of its more uniform molecular structure. The rubbery domains in impact copolymers create superior stress distribution, making them ideal for applications requiring high durability and resistance to cracking.

Applications of Random Copolymer Polypropylene

Random copolymer polypropylene is widely used in applications requiring superior clarity and flexibility, such as food packaging films and medical device components. Its enhanced transparency and low-temperature resistance make it ideal for containers, lids, and household products. Unlike impact copolymer, which is preferred for toughness and impact resistance in automotive and industrial parts, random copolymer excels in applications where aesthetic appeal and flexibility are critical.

Applications of Impact Copolymer Polypropylene

Impact copolymer polypropylene offers enhanced toughness and impact resistance compared to random copolymer, making it ideal for automotive components, packaging materials, and household appliances. Its improved mechanical properties enable use in products requiring durability under stress and low temperatures, such as protective gear and refrigerator interiors. The addition of ethylene segments in impact copolymer polypropylene enhances flexibility and impact strength, extending its application range in demanding environments.

Cost Considerations: Random Copolymer vs Impact Copolymer

Random copolymer polypropylene typically costs more than impact copolymer due to its higher clarity and better aesthetic properties, which require more precise polymerization control. Impact copolymer is generally more cost-effective, offering enhanced toughness and impact resistance at a lower price point, making it ideal for applications where durability is prioritized over appearance. Manufacturers often balance cost with performance needs, selecting random copolymer for premium applications and impact copolymer for budget-sensitive, impact-resistant products.

Choosing the Right Polypropylene Copolymer for Your Application

Random copolymer polypropylene offers superior clarity and flexibility, making it ideal for applications requiring intricate designs and excellent aesthetic appeal, such as packaging and medical devices. Impact copolymer polypropylene combines high impact resistance with toughness due to its rubber phase, making it suitable for automotive parts, appliances, and industrial uses that demand durability. Selecting the appropriate polypropylene copolymer depends on balancing the need for transparency and flexibility against mechanical strength and impact resistance to optimize performance in specific applications.

Random Copolymer vs Impact Copolymer Infographic

materialdif.com

materialdif.com