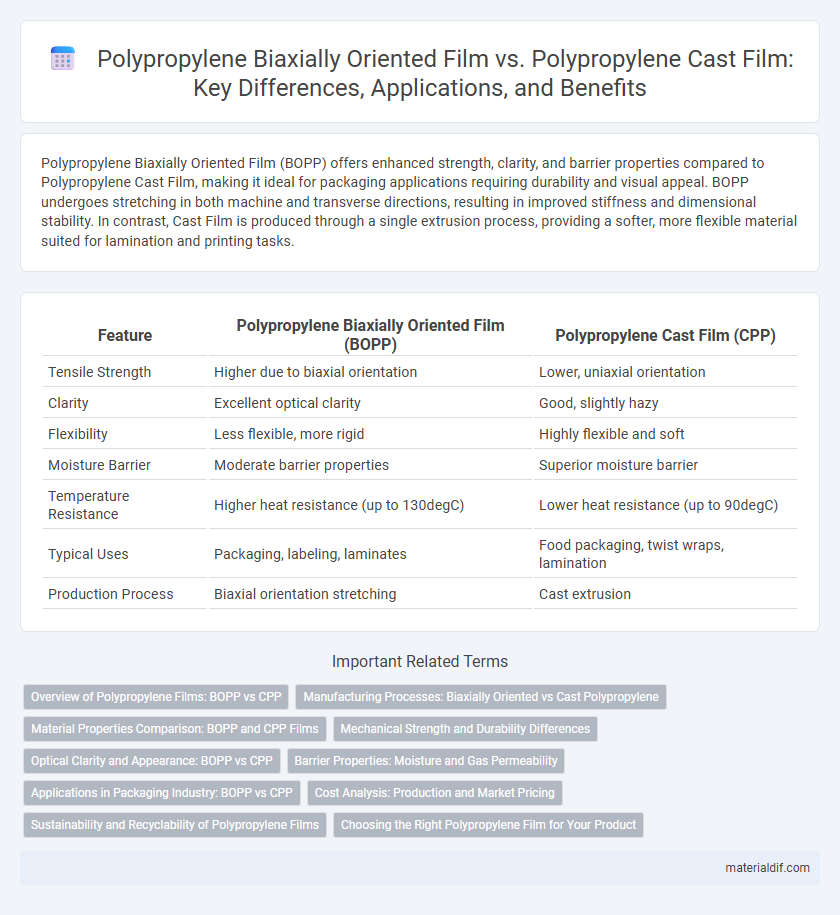

Polypropylene Biaxially Oriented Film (BOPP) offers enhanced strength, clarity, and barrier properties compared to Polypropylene Cast Film, making it ideal for packaging applications requiring durability and visual appeal. BOPP undergoes stretching in both machine and transverse directions, resulting in improved stiffness and dimensional stability. In contrast, Cast Film is produced through a single extrusion process, providing a softer, more flexible material suited for lamination and printing tasks.

Table of Comparison

| Feature | Polypropylene Biaxially Oriented Film (BOPP) | Polypropylene Cast Film (CPP) |

|---|---|---|

| Tensile Strength | Higher due to biaxial orientation | Lower, uniaxial orientation |

| Clarity | Excellent optical clarity | Good, slightly hazy |

| Flexibility | Less flexible, more rigid | Highly flexible and soft |

| Moisture Barrier | Moderate barrier properties | Superior moisture barrier |

| Temperature Resistance | Higher heat resistance (up to 130degC) | Lower heat resistance (up to 90degC) |

| Typical Uses | Packaging, labeling, laminates | Food packaging, twist wraps, lamination |

| Production Process | Biaxial orientation stretching | Cast extrusion |

Overview of Polypropylene Films: BOPP vs CPP

Polypropylene films are widely used in packaging, with Biaxially Oriented Polypropylene (BOPP) and Cast Polypropylene (CPP) being the two main types. BOPP films are stretched in both the machine and transverse directions, resulting in superior tensile strength, clarity, and barrier properties suitable for high-quality packaging. CPP films are produced through a cast extrusion process, offering excellent heat sealing, flexibility, and resistance to puncture, making them ideal for applications requiring strong seals and durability.

Manufacturing Processes: Biaxially Oriented vs Cast Polypropylene

Polypropylene Biaxially Oriented Film (BOPP) is produced by stretching the film both longitudinally and transversely, which enhances its mechanical strength, clarity, and barrier properties. In contrast, Polypropylene Cast Film (CPP) is manufactured by extruding molten polymer onto a chill roll, resulting in a film with excellent clarity and sealability but lower tensile strength compared to BOPP. The biaxial orientation process involves sequential stretching and heat setting, while the cast process relies on rapid cooling and solidification, impacting the physical and optical characteristics of the final film.

Material Properties Comparison: BOPP and CPP Films

Polypropylene biaxially oriented film (BOPP) exhibits superior tensile strength, clarity, and moisture barrier properties compared to polypropylene cast film (CPP), making BOPP ideal for high-performance packaging applications. BOPP films undergo stretching in both machine and transverse directions, enhancing dimensional stability and stiffness, whereas CPP films, produced via a single extrusion process, offer higher impact resistance and heat resistance but lower transparency. The choice between BOPP and CPP depends on specific material property requirements such as transparency, strength, and thermal stability for packaging or labeling uses.

Mechanical Strength and Durability Differences

Polypropylene Biaxially Oriented Film (BOPP) exhibits superior mechanical strength and durability compared to Polypropylene Cast Film due to its biaxial stretching process, which enhances tensile strength, stiffness, and impact resistance. The molecular alignment in BOPP film creates a more uniform and robust structure, resulting in improved dimensional stability and resistance to tears and punctures. Conversely, Cast Film, produced through a cooling and solidification process, offers lower mechanical strength but greater clarity and flexibility, making it less durable under mechanical stress.

Optical Clarity and Appearance: BOPP vs CPP

Polypropylene Biaxially Oriented Film (BOPP) offers superior optical clarity and a glossy, high-quality appearance compared to Polypropylene Cast Film (CPP), which typically exhibits a more matte finish and lower transparency. BOPP's enhanced transparency and gloss result from its biaxial orientation process, improving light transmission and surface smoothness. These optical properties make BOPP the preferred choice for applications demanding premium visual appeal, such as food packaging and labels.

Barrier Properties: Moisture and Gas Permeability

Polypropylene Biaxially Oriented Film (BOPP) exhibits superior barrier properties against moisture and gases compared to Polypropylene Cast Film (CPP) due to its stretched molecular structure, which enhances film density and reduces permeability. BOPP film's biaxial orientation significantly diminishes water vapor transmission rates (WVTR) and oxygen transmission rates (OTR), making it ideal for food packaging applications requiring extended shelf life. In contrast, CPP films have higher moisture permeability and lower gas barrier effectiveness, limiting their use where stringent protection from environmental factors is necessary.

Applications in Packaging Industry: BOPP vs CPP

Polypropylene Biaxially Oriented Film (BOPP) and Polypropylene Cast Film (CPP) serve distinct roles in the packaging industry due to their differing mechanical properties. BOPP offers high tensile strength, stiffness, and excellent moisture barrier, making it ideal for food packaging, snack wrappers, and labels requiring high clarity and durability. CPP provides superior heat sealability and flexibility, often used for flexible food packaging, lamination, and packaging requiring reliable sealing performance under diverse temperature conditions.

Cost Analysis: Production and Market Pricing

Polypropylene Biaxially Oriented Film (BOPP) generally incurs higher production costs due to its complex biaxial stretching process, which enhances mechanical strength and clarity but requires advanced machinery and energy input. In contrast, Polypropylene Cast Film (CPP) is produced through a simpler extrusion and casting method, resulting in lower manufacturing expenses and faster production speeds. Market pricing reflects these differences, with BOPP films commanding premium prices in packaging applications that demand superior barrier properties, while CPP films offer cost-effective solutions for flexible packaging with moderate barrier requirements.

Sustainability and Recyclability of Polypropylene Films

Polypropylene biaxially oriented (BOPP) film demonstrates enhanced mechanical properties compared to cast polypropylene film, which can extend product lifecycle and reduce material waste, supporting sustainability goals. Both BOPP and cast films are recyclable within polypropylene waste streams, but BOPP's uniform molecular orientation facilitates more efficient recycling processes and higher-quality recycled output. Advances in recycling technologies further improve the circularity of polypropylene films, minimizing environmental impact and promoting resource conservation in packaging industries.

Choosing the Right Polypropylene Film for Your Product

Biaxially oriented polypropylene (BOPP) film offers superior tensile strength, clarity, and barrier properties, making it ideal for flexible packaging applications requiring durability and printability. Polypropylene cast film provides excellent gloss, flexibility, and heat-sealability, suitable for products needing soft feel and superior sealing performance. Selecting the right polypropylene film depends on your product's packaging requirements for strength, appearance, and sealing characteristics to ensure optimal protection and presentation.

Polypropylene Biaxially Oriented Film vs Polypropylene Cast Film Infographic

materialdif.com

materialdif.com