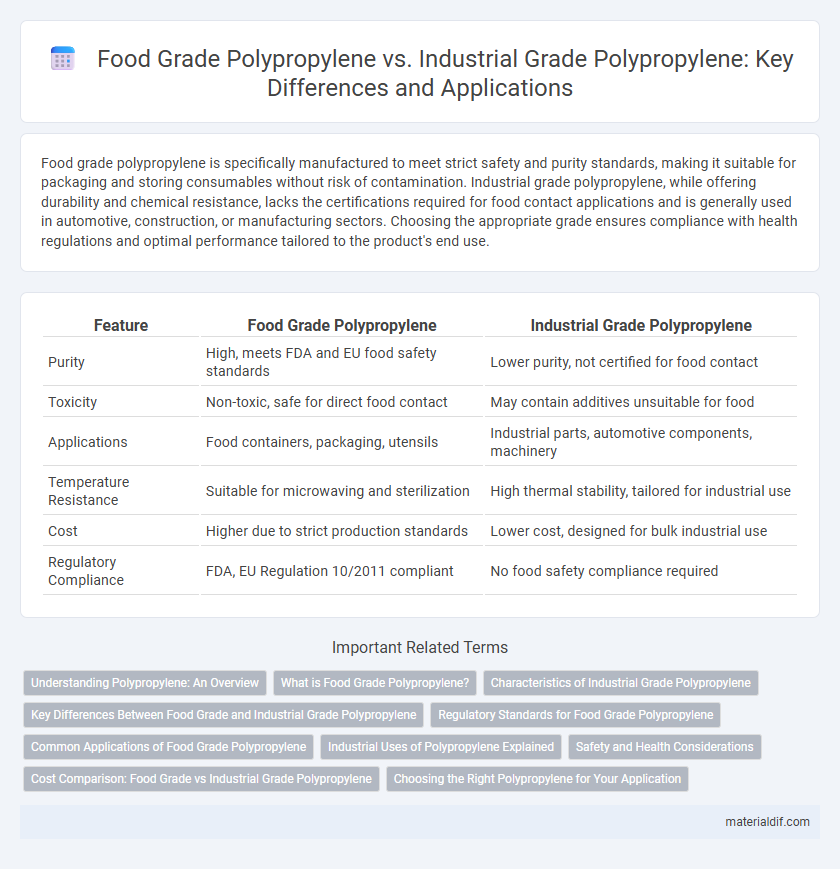

Food grade polypropylene is specifically manufactured to meet strict safety and purity standards, making it suitable for packaging and storing consumables without risk of contamination. Industrial grade polypropylene, while offering durability and chemical resistance, lacks the certifications required for food contact applications and is generally used in automotive, construction, or manufacturing sectors. Choosing the appropriate grade ensures compliance with health regulations and optimal performance tailored to the product's end use.

Table of Comparison

| Feature | Food Grade Polypropylene | Industrial Grade Polypropylene |

|---|---|---|

| Purity | High, meets FDA and EU food safety standards | Lower purity, not certified for food contact |

| Toxicity | Non-toxic, safe for direct food contact | May contain additives unsuitable for food |

| Applications | Food containers, packaging, utensils | Industrial parts, automotive components, machinery |

| Temperature Resistance | Suitable for microwaving and sterilization | High thermal stability, tailored for industrial use |

| Cost | Higher due to strict production standards | Lower cost, designed for bulk industrial use |

| Regulatory Compliance | FDA, EU Regulation 10/2011 compliant | No food safety compliance required |

Understanding Polypropylene: An Overview

Food grade polypropylene meets strict FDA regulations for safety and is commonly used in packaging, containers, and utensils that come into direct contact with food. Industrial grade polypropylene offers higher durability and chemical resistance, making it suitable for automotive parts, piping, and manufacturing applications. Understanding the differences helps optimize material selection based on regulatory compliance and performance requirements.

What is Food Grade Polypropylene?

Food grade polypropylene is a type of polypropylene specifically formulated and tested to meet strict safety standards for direct contact with food and beverages, ensuring it is non-toxic and free from harmful chemicals. It complies with regulations set by agencies such as the FDA and EFSA, making it suitable for use in packaging, containers, and kitchenware. This grade of polypropylene offers durability, chemical resistance, and heat tolerance while maintaining food safety standards essential for consumer health.

Characteristics of Industrial Grade Polypropylene

Industrial grade polypropylene is designed for durability and chemical resistance, making it suitable for manufacturing automotive parts, containers, and piping systems. It typically contains additives that enhance heat resistance and mechanical strength but render it unsuitable for direct food contact due to potential contamination risks. This grade's physical properties include higher toughness and impact resistance compared to food grade polypropylene, prioritizing functionality over food safety compliance.

Key Differences Between Food Grade and Industrial Grade Polypropylene

Food grade polypropylene is specially formulated to meet strict FDA and EU regulations, ensuring it is non-toxic, odorless, and safe for direct contact with food products. Industrial grade polypropylene lacks these certifications, often containing additives or impurities making it unsuitable for food-related applications but ideal for packaging, automotive parts, and household goods. The key differences lie in purity standards, regulatory compliance, and the intended application environment, with food grade prioritizing safety and hygiene.

Regulatory Standards for Food Grade Polypropylene

Food grade polypropylene complies with stringent regulatory standards such as FDA 21 CFR 177.1520 and EU Regulation No. 10/2011, ensuring it is safe for direct food contact with no harmful migration of chemicals. Industrial grade polypropylene lacks these certifications and may contain additives or contaminants unsuitable for food applications. Compliance with these food safety regulations guarantees the hygienic and toxicologically safe use of food grade polypropylene in packaging and storage.

Common Applications of Food Grade Polypropylene

Food grade polypropylene is primarily used in the packaging of consumables, including containers for dairy products, microwave-safe food trays, and reusable food storage boxes, ensuring safety and compliance with FDA regulations. Its chemical resistance and non-toxicity make it ideal for manufacturing kitchen utensils, disposable cups, and bottle caps. Unlike industrial grade polypropylene, which is geared towards automotive parts and construction materials, food grade polypropylene maintains strict standards to prevent contamination and preserve food quality.

Industrial Uses of Polypropylene Explained

Industrial grade polypropylene is engineered for high durability and chemical resistance, making it ideal for automotive parts, electrical components, and packaging applications in harsh environments. It exhibits excellent mechanical properties, such as impact strength and heat resistance, essential for manufacturing pipes, containers, and textile fibers used in industrial settings. In contrast to food grade polypropylene, which must meet stringent FDA regulations for safety and contamination prevention, industrial grade prioritizes performance characteristics suited for structural and mechanical functions.

Safety and Health Considerations

Food grade polypropylene is manufactured to meet strict FDA and EU regulations ensuring it is free from harmful chemicals and suitable for direct contact with food, minimizing health risks. Industrial grade polypropylene lacks these certifications and may contain additives or contaminants unsafe for food use, posing potential hazards if ingested. Selecting food grade polypropylene guarantees compliance with safety standards critical for food packaging, storage, and preparation applications.

Cost Comparison: Food Grade vs Industrial Grade Polypropylene

Food grade polypropylene typically incurs higher costs due to stringent regulatory compliance and safety standards ensuring non-toxicity and suitability for direct food contact. Industrial grade polypropylene, lacking these certifications, is more affordable and used in applications where food safety is not a concern. Price differences can range from 10% to 30%, reflecting the added processing and quality control necessary for food grade variants.

Choosing the Right Polypropylene for Your Application

Food grade polypropylene meets strict FDA and EU safety standards, making it ideal for packaging, storage containers, and utensils in direct contact with food. Industrial grade polypropylene, while offering enhanced chemical resistance and mechanical strength, is better suited for automotive parts, electrical components, and industrial machinery. Selecting the right polypropylene depends on the specific application requirements, including safety regulations, durability, and exposure to chemicals or heat.

Food Grade Polypropylene vs Industrial Grade Polypropylene Infographic

materialdif.com

materialdif.com