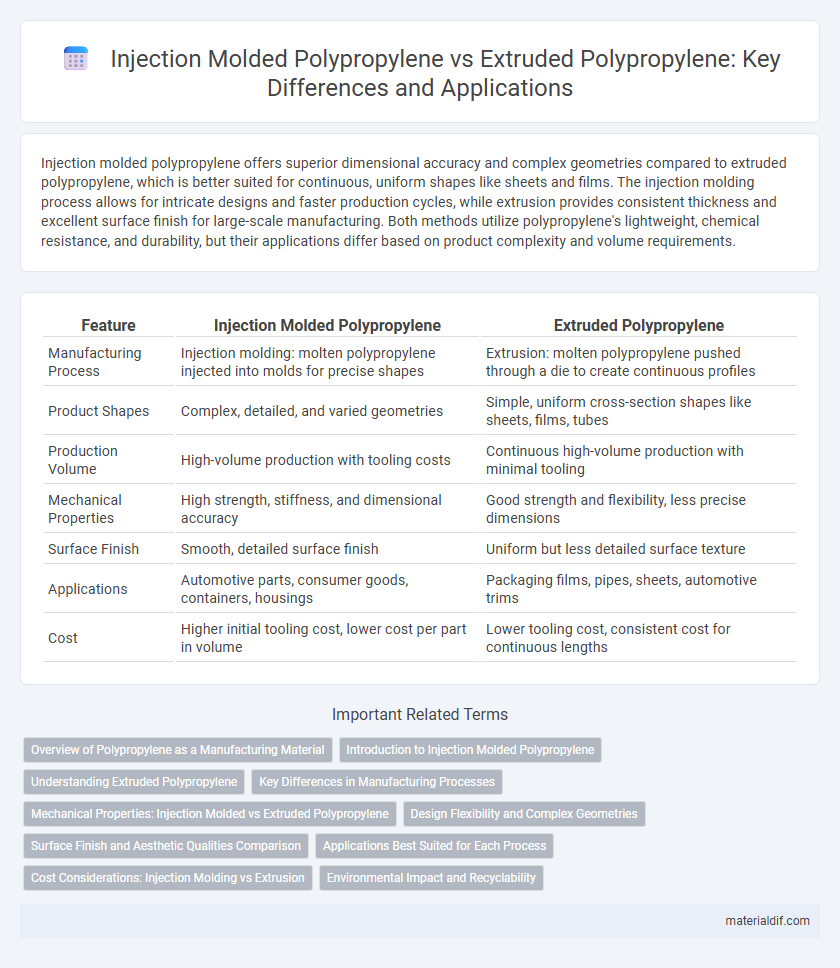

Injection molded polypropylene offers superior dimensional accuracy and complex geometries compared to extruded polypropylene, which is better suited for continuous, uniform shapes like sheets and films. The injection molding process allows for intricate designs and faster production cycles, while extrusion provides consistent thickness and excellent surface finish for large-scale manufacturing. Both methods utilize polypropylene's lightweight, chemical resistance, and durability, but their applications differ based on product complexity and volume requirements.

Table of Comparison

| Feature | Injection Molded Polypropylene | Extruded Polypropylene |

|---|---|---|

| Manufacturing Process | Injection molding: molten polypropylene injected into molds for precise shapes | Extrusion: molten polypropylene pushed through a die to create continuous profiles |

| Product Shapes | Complex, detailed, and varied geometries | Simple, uniform cross-section shapes like sheets, films, tubes |

| Production Volume | High-volume production with tooling costs | Continuous high-volume production with minimal tooling |

| Mechanical Properties | High strength, stiffness, and dimensional accuracy | Good strength and flexibility, less precise dimensions |

| Surface Finish | Smooth, detailed surface finish | Uniform but less detailed surface texture |

| Applications | Automotive parts, consumer goods, containers, housings | Packaging films, pipes, sheets, automotive trims |

| Cost | Higher initial tooling cost, lower cost per part in volume | Lower tooling cost, consistent cost for continuous lengths |

Overview of Polypropylene as a Manufacturing Material

Polypropylene is a versatile thermoplastic polymer widely used in manufacturing due to its excellent chemical resistance, low density, and high impact strength. Injection molded polypropylene allows for detailed, complex shapes with tight tolerances and faster production cycles, ideal for intricate components. Extruded polypropylene produces continuous profiles such as sheets, tubes, and films, emphasizing uniform thickness and material consistency for applications like packaging and automotive parts.

Introduction to Injection Molded Polypropylene

Injection molded polypropylene offers precise dimensional control and complex geometries, making it ideal for producing high-volume, detailed parts. This process heats polypropylene pellets until molten and injects them into molds, resulting in strong, durable components with minimal waste. Compared to extruded polypropylene, injection molding allows for diverse shapes and tighter tolerances suitable for automotive, consumer goods, and medical applications.

Understanding Extruded Polypropylene

Extruded polypropylene is produced by continuously forcing molten polypropylene through a shaped die, creating uniform sheets, films, or profiles with consistent thickness and mechanical properties. This process enhances dimensional stability and surface finish, making extruded polypropylene ideal for applications such as packaging, automotive trim, and piping. Unlike injection molded polypropylene, extruded polypropylene offers better flexibility and is suited for large-volume, continuous production runs.

Key Differences in Manufacturing Processes

Injection molded polypropylene involves melting plastic pellets and injecting them into a mold cavity under high pressure, allowing for precise, complex shapes with tight tolerances and smooth surface finishes. Extruded polypropylene is produced by continuously forcing melted polymer through a shaped die, creating long, continuous profiles with uniform cross-sections ideal for pipes, sheets, and films. The key differences lie in production speed, complexity of shapes achievable, and end-use applications, with injection molding suited for detailed, high-volume parts and extrusion for consistent, simple geometry components.

Mechanical Properties: Injection Molded vs Extruded Polypropylene

Injection molded polypropylene typically exhibits higher tensile strength and better dimensional stability due to controlled cooling and cavity pressure during processing. Extruded polypropylene often displays improved impact resistance and flexibility, as the continuous extrusion process aligns polymer chains differently and reduces internal stresses. Mechanical properties such as modulus of elasticity and elongation at break vary between injection molded and extruded polypropylene, influencing their suitability for applications requiring stiffness or toughness.

Design Flexibility and Complex Geometries

Injection molded polypropylene offers superior design flexibility and the ability to create highly complex geometries due to the precision of mold cavities and consistent flow of molten polymer. Extruded polypropylene is better suited for simpler, continuous cross-sectional profiles but lacks the capacity to produce intricate shapes or variable wall thicknesses found in injection molding. The choice between injection molding and extrusion depends on the required complexity, detail, and customization of the polypropylene part.

Surface Finish and Aesthetic Qualities Comparison

Injection molded polypropylene typically exhibits a smoother and more refined surface finish due to the high pressure and precise cavity filling during molding, enabling intricate textures and glossy appearances. Extruded polypropylene often has a more uniform but less detailed surface, with a matte or slightly textured finish influenced by the die and cooling methods. The aesthetic quality of injection molded parts is superior for applications requiring fine details and visual appeal, while extruded polypropylene is ideal for consistent, large-scale profiles with moderate surface requirements.

Applications Best Suited for Each Process

Injection molded polypropylene is ideal for producing complex, high-precision components such as automotive parts, medical devices, and consumer goods requiring detailed features and tight tolerances. Extruded polypropylene, on the other hand, is best suited for continuous profiles like sheets, films, pipes, and packaging materials where uniform thickness and length consistency are essential. Each process leverages polypropylene's chemical resistance and durability tailored to specific manufacturing demands and end-use applications.

Cost Considerations: Injection Molding vs Extrusion

Injection molded polypropylene generally incurs higher initial tooling costs due to the complexity of mold design, making it more suitable for high-volume production runs to offset expenses. Extruded polypropylene features lower startup costs and faster production rates, offering cost-effective solutions for continuous profiles and simpler shapes. Material waste is typically lower in extrusion processes, enhancing overall cost efficiency compared to injection molding.

Environmental Impact and Recyclability

Injection molded polypropylene typically generates less material waste due to precise mold control and shorter cycle times, resulting in lower environmental impact compared to extruded polypropylene, which may produce more scrap during trimming processes. Both forms of polypropylene are highly recyclable, with injection molded parts often easier to collect and reprocess because of their defined shapes and consistent material composition. Recycling facilities efficiently handle polypropylene resins, reducing landfill dependency and supporting circular economy initiatives in both injection molding and extrusion applications.

Injection Molded Polypropylene vs Extruded Polypropylene Infographic

materialdif.com

materialdif.com