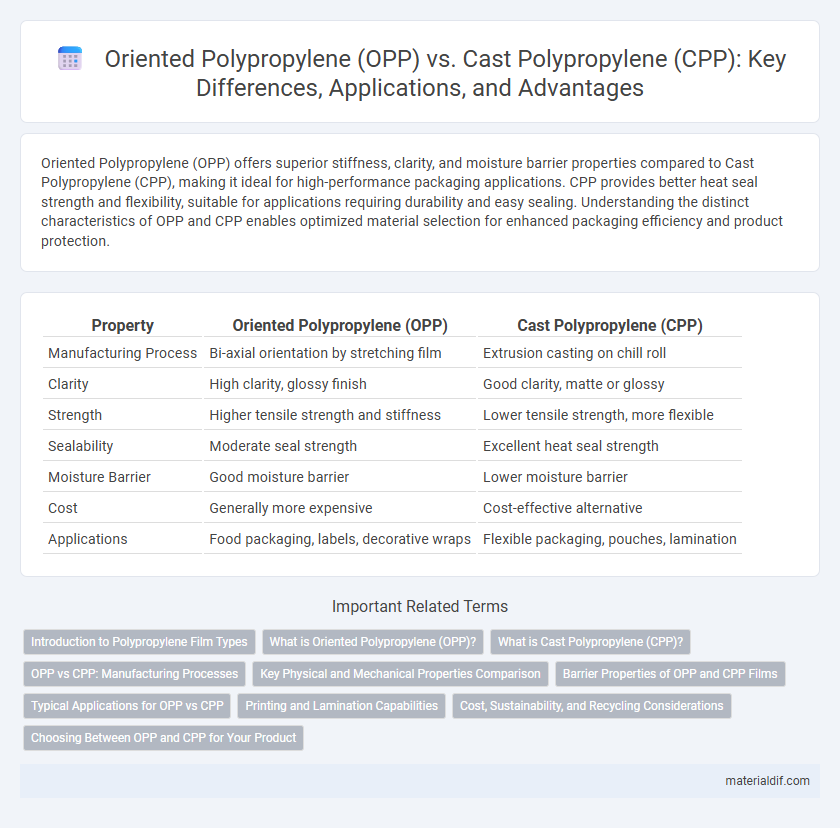

Oriented Polypropylene (OPP) offers superior stiffness, clarity, and moisture barrier properties compared to Cast Polypropylene (CPP), making it ideal for high-performance packaging applications. CPP provides better heat seal strength and flexibility, suitable for applications requiring durability and easy sealing. Understanding the distinct characteristics of OPP and CPP enables optimized material selection for enhanced packaging efficiency and product protection.

Table of Comparison

| Property | Oriented Polypropylene (OPP) | Cast Polypropylene (CPP) |

|---|---|---|

| Manufacturing Process | Bi-axial orientation by stretching film | Extrusion casting on chill roll |

| Clarity | High clarity, glossy finish | Good clarity, matte or glossy |

| Strength | Higher tensile strength and stiffness | Lower tensile strength, more flexible |

| Sealability | Moderate seal strength | Excellent heat seal strength |

| Moisture Barrier | Good moisture barrier | Lower moisture barrier |

| Cost | Generally more expensive | Cost-effective alternative |

| Applications | Food packaging, labels, decorative wraps | Flexible packaging, pouches, lamination |

Introduction to Polypropylene Film Types

Oriented Polypropylene (OPP) and Cast Polypropylene (CPP) are two primary types of polypropylene films widely used in packaging. OPP films exhibit biaxial orientation, resulting in higher tensile strength, clarity, and stiffness, making them ideal for high-quality labeling and flexible packaging applications. CPP films are produced through a cast extrusion process, delivering superior sealability, softness, and impact resistance, which suits them for applications requiring heat sealing and enhanced durability.

What is Oriented Polypropylene (OPP)?

Oriented Polypropylene (OPP) is a type of polypropylene film that is stretched in one or two directions to enhance its strength, clarity, and barrier properties. This biaxial or uniaxial orientation aligns the polymer molecules, resulting in improved tensile strength and stiffness compared to Cast Polypropylene (CPP). OPP is widely used in packaging applications where high transparency and printability are essential, such as food wrapping and labels.

What is Cast Polypropylene (CPP)?

Cast Polypropylene (CPP) is a versatile polypropylene film produced by extruding the molten polymer onto a chill roll, resulting in a thicker, softer, and more flexible material compared to Oriented Polypropylene (OPP). CPP films exhibit excellent heat sealability, moisture resistance, and high clarity, making them ideal for food packaging, labeling, and lamination applications. Its non-oriented structure provides superior impact strength and elongation, enhancing durability and performance in packaging solutions.

OPP vs CPP: Manufacturing Processes

Oriented Polypropylene (OPP) is produced by stretching polypropylene film in both the machine and transverse directions, enhancing its strength, clarity, and barrier properties. Cast Polypropylene (CPP) is manufactured by extruding molten polymer onto a chill roll, rapidly solidifying the film without orientation, resulting in a thicker, more flexible film with excellent heat resistance. The biaxial orientation in OPP improves tensile strength and stiffness, while the cast process for CPP offers superior sealing properties and elongation.

Key Physical and Mechanical Properties Comparison

Oriented Polypropylene (OPP) exhibits superior tensile strength and clarity compared to Cast Polypropylene (CPP), making it ideal for packaging applications requiring high durability and visual appeal. OPP films typically have higher stiffness and better dimensional stability, while CPP offers greater toughness and elongation at break, enhancing flexibility and resistance to impact. Both materials differ in crystallinity and molecular orientation, directly influencing properties such as barrier performance, seal strength, and moisture resistance critical for food packaging.

Barrier Properties of OPP and CPP Films

Oriented Polypropylene (OPP) films exhibit superior barrier properties against moisture and oxygen compared to Cast Polypropylene (CPP) films, making them ideal for packaging applications requiring extended shelf life. OPP films demonstrate higher tensile strength and better clarity, enhancing product protection and visual appeal, whereas CPP films offer better heat sealability but lower moisture barrier efficiency. The improved barrier performance of OPP is attributed to its biaxial orientation process, which aligns polymer chains and reduces permeability.

Typical Applications for OPP vs CPP

Oriented Polypropylene (OPP) is commonly used in packaging applications such as snack wrappers, labels, and tape due to its high tensile strength, clarity, and moisture resistance. Cast Polypropylene (CPP) is favored in flexible packaging for food products, medical supplies, and lamination films because of its excellent heat sealability, softness, and clarity. Both materials serve key roles in packaging, with OPP excelling in rigidity and printability while CPP provides superior flexibility and seal performance.

Printing and Lamination Capabilities

Oriented Polypropylene (OPP) offers superior print clarity and surface gloss, making it ideal for high-quality packaging graphics and detailed designs. Cast Polypropylene (CPP) provides better lamination properties due to its softer texture and lower melting point, enabling stronger bonds with other substrates and flexible films. OPP's enhanced dimensional stability supports precise printing processes, whereas CPP's lamination flexibility suits multi-layer packaging applications requiring durability and seal strength.

Cost, Sustainability, and Recycling Considerations

Oriented Polypropylene (OPP) typically offers lower cost per unit due to its high-speed production process, whereas Cast Polypropylene (CPP) involves higher energy consumption but provides superior barrier properties, influencing overall sustainability profiles. OPP's mono-material structure enhances recyclability compared to the multi-layered CPP films often laminated with other plastics, complicating recycling streams. Despite CPP's higher tensile strength and heat resistance, OPP films generally contribute to reduced environmental impact through easier separation and lower resource intensity in recycling programs.

Choosing Between OPP and CPP for Your Product

Choosing between Oriented Polypropylene (OPP) and Cast Polypropylene (CPP) depends on product requirements such as clarity, strength, and flexibility. OPP offers excellent tensile strength and high clarity, making it ideal for packaging that demands visual appeal and protection. CPP provides superior flexibility and heat resistance, suitable for products requiring durability and easy sealing.

Oriented Polypropylene (OPP) vs Cast Polypropylene (CPP) Infographic

materialdif.com

materialdif.com