Filled polypropylene incorporates additives such as glass fibers, calcium carbonate, or talc to enhance mechanical strength, stiffness, and heat resistance compared to unfilled polypropylene. Unfilled polypropylene offers greater flexibility, impact resistance, and is easier to process, making it suitable for lightweight applications. The choice between filled and unfilled polypropylene depends on the specific requirements for durability, weight, and cost efficiency in end-use products.

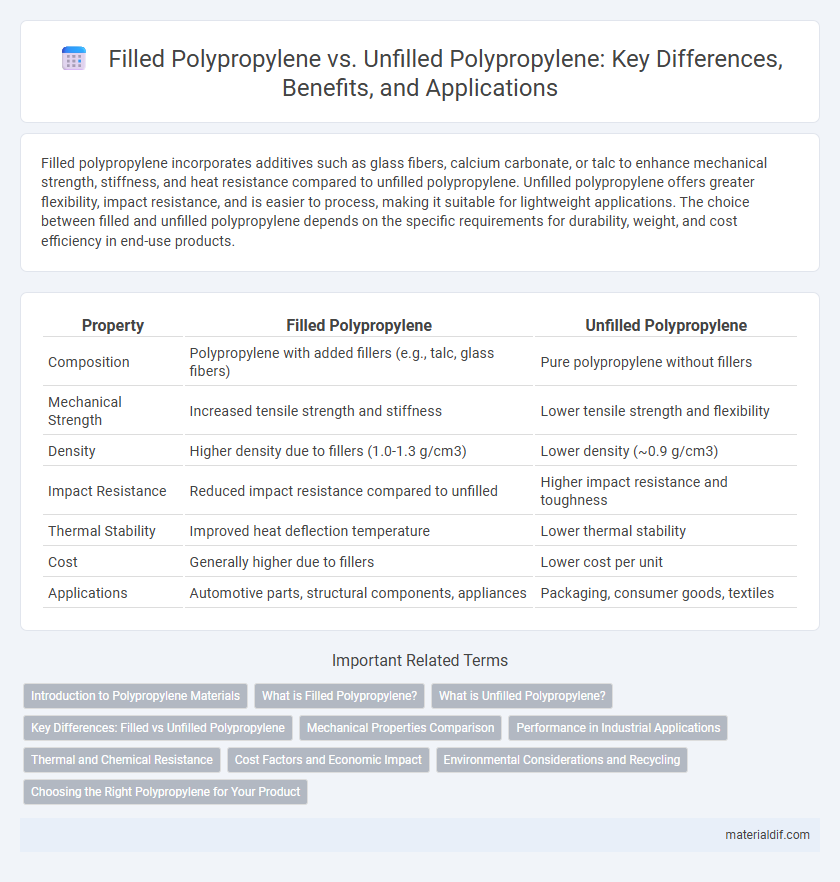

Table of Comparison

| Property | Filled Polypropylene | Unfilled Polypropylene |

|---|---|---|

| Composition | Polypropylene with added fillers (e.g., talc, glass fibers) | Pure polypropylene without fillers |

| Mechanical Strength | Increased tensile strength and stiffness | Lower tensile strength and flexibility |

| Density | Higher density due to fillers (1.0-1.3 g/cm3) | Lower density (~0.9 g/cm3) |

| Impact Resistance | Reduced impact resistance compared to unfilled | Higher impact resistance and toughness |

| Thermal Stability | Improved heat deflection temperature | Lower thermal stability |

| Cost | Generally higher due to fillers | Lower cost per unit |

| Applications | Automotive parts, structural components, appliances | Packaging, consumer goods, textiles |

Introduction to Polypropylene Materials

Filled polypropylene incorporates additives like glass fibers or talc to enhance mechanical strength, thermal resistance, and dimensional stability compared to unfilled polypropylene. Unfilled polypropylene offers excellent chemical resistance, flexibility, and cost-effectiveness but has lower rigidity and heat resistance. Choosing between filled and unfilled polypropylene depends on application requirements such as durability, weight, and environmental exposure.

What is Filled Polypropylene?

Filled polypropylene is a composite material where additives like glass fibers, talc, or calcium carbonate are incorporated into the polypropylene matrix to enhance mechanical properties such as stiffness, tensile strength, and dimensional stability. These fillers improve heat resistance and reduce shrinkage, making filled polypropylene suitable for automotive parts, construction, and industrial applications. Unlike unfilled polypropylene, which is pure and more flexible, filled polypropylene offers increased rigidity and durability tailored for demanding environments.

What is Unfilled Polypropylene?

Unfilled polypropylene is a thermoplastic polymer composed solely of the base polypropylene material without any added fillers or reinforcements. It offers excellent chemical resistance, flexibility, and ease of processing, making it suitable for injection molding and extrusion applications. Unfilled polypropylene is widely used in packaging, automotive parts, and consumer goods where high impact strength and lightweight properties are essential.

Key Differences: Filled vs Unfilled Polypropylene

Filled polypropylene contains additives such as glass fibers, talc, or calcium carbonate to enhance mechanical properties like stiffness, impact resistance, and thermal stability, while unfilled polypropylene offers greater flexibility and is more cost-effective. Filled polypropylene typically exhibits improved dimensional stability and higher tensile strength, making it suitable for automotive and industrial applications, whereas unfilled polypropylene is preferred for packaging and consumer goods due to its lighter weight and ease of processing. The choice between filled and unfilled polypropylene depends on the specific performance requirements, including strength, durability, and cost considerations.

Mechanical Properties Comparison

Filled polypropylene exhibits enhanced mechanical properties compared to unfilled polypropylene, including increased tensile strength, stiffness, and dimensional stability due to the incorporation of fillers such as glass fibers or talc. Unfilled polypropylene, while having lower strength and rigidity, offers greater impact resistance and flexibility, making it suitable for applications requiring toughness. The choice between filled and unfilled polypropylene depends on specific performance requirements, balancing mechanical strength with impact resilience.

Performance in Industrial Applications

Filled polypropylene exhibits enhanced mechanical strength, improved dimensional stability, and increased resistance to wear and heat compared to unfilled polypropylene. Industrial applications benefit from filled variants, particularly in automotive and construction sectors, where load-bearing capacity and durability are critical. Unfilled polypropylene offers superior flexibility and chemical resistance, making it suitable for applications requiring lightweight and corrosion-resistant materials.

Thermal and Chemical Resistance

Filled polypropylene exhibits enhanced thermal stability and improved resistance to chemical degradation compared to unfilled polypropylene, due to the addition of fillers such as glass fibers or mineral additives. These fillers increase the material's heat deflection temperature and improve dimensional stability under thermal stress, making filled polypropylene suitable for higher temperature applications. Unfilled polypropylene, while offering good chemical resistance to acids, bases, and solvents, generally has lower thermal resistance and may deform under prolonged exposure to elevated temperatures.

Cost Factors and Economic Impact

Filled polypropylene typically incurs higher material costs due to the addition of reinforcements like talc, glass fibers, or calcium carbonate, which improve mechanical properties but increase production expenses. Unfilled polypropylene offers lower raw material costs and simpler processing, making it economically advantageous for applications where enhanced strength is not critical. The choice between filled and unfilled polypropylene significantly impacts overall manufacturing cost, influencing product pricing and profitability depending on performance requirements and volume.

Environmental Considerations and Recycling

Filled polypropylene often contains additives like glass fibers or mineral fillers that improve mechanical properties but complicate recycling due to the need for separation and potential contamination of recycling streams. Unfilled polypropylene, being pure polymer, offers easier recyclability with fewer processing challenges and lower environmental impact during reprocessing. Environmental considerations favor unfilled polypropylene for circular economy practices, whereas filled grades require advanced recycling technologies to mitigate waste and pollution.

Choosing the Right Polypropylene for Your Product

Filled polypropylene offers enhanced mechanical properties such as increased stiffness, impact resistance, and thermal stability compared to unfilled polypropylene, making it suitable for applications requiring durability and structural integrity. Unfilled polypropylene provides greater flexibility, lower density, and improved processability, ideal for products that prioritize lightweight design and easier fabrication. Selecting the right polypropylene depends on the specific performance requirements of the product, balancing factors like strength, weight, and cost-effectiveness.

Filled Polypropylene vs Unfilled Polypropylene Infographic

materialdif.com

materialdif.com